Dabigatran etexilate mesylate and preparation method thereof

A technology for dabigatran etexilate mesylate and aminobenzamidine dihydrochloride is applied in the field of chemical and pharmaceutical preparation, and can solve the problem of high raw material prices, unfavorable market promotion, and production of dabigatran etexilate mesylate. Low production rate and other problems, to achieve the effect of reducing production cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of dabigatran etexilate mesylate, is made by following steps:

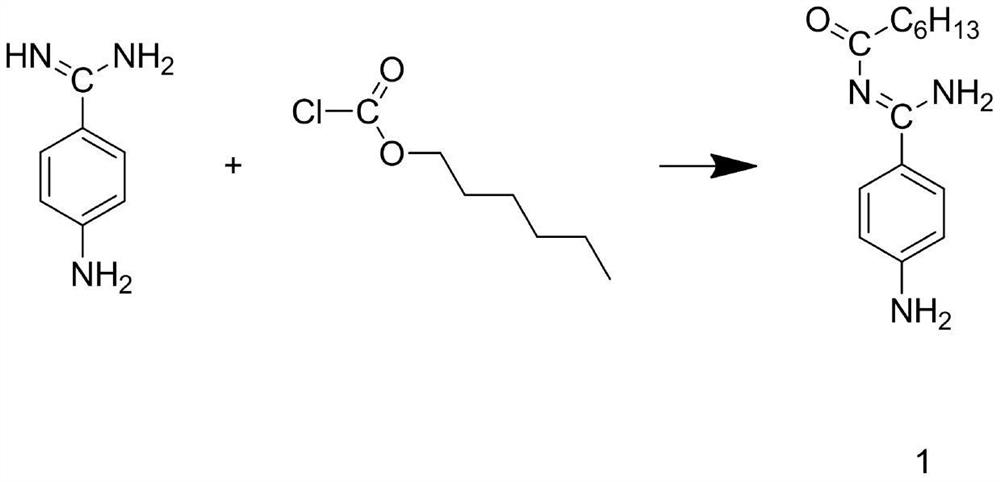

[0040] Step S1: Add 4-aminobenzamidine dihydrochloride, toluene, triethylamine, and deionized water into the reaction kettle, stir for 10 minutes at a rotation speed of 200r / min and a temperature of 25°C, and then cool down At a temperature of 5°C, n-hexyl chloroformate was added dropwise at a rate of 0.1 L / h, and the reaction was carried out for 1 hour. At a temperature of 120°C, toluene and water were distilled off to obtain intermediate 1;

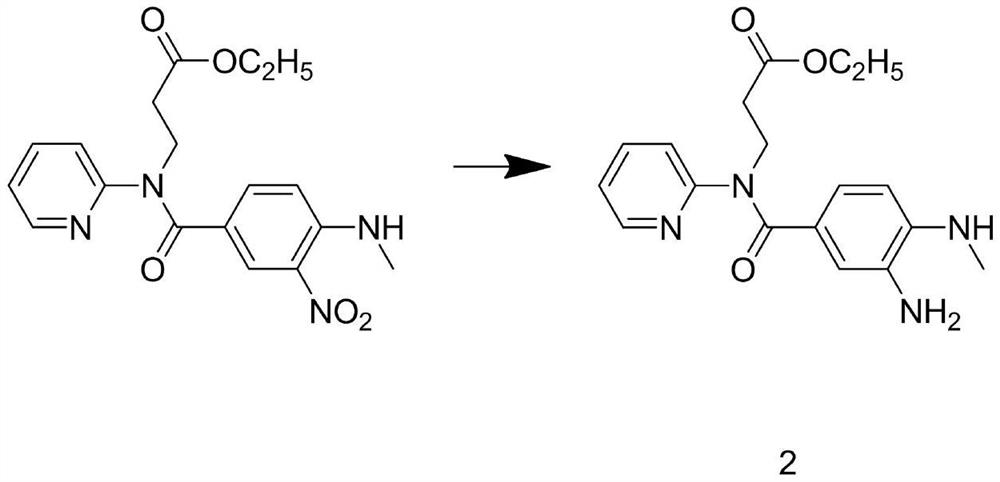

[0041] Step S2: Add ethyl 3-(4-(methylamino)-3-nitro-N-(pyridin-2-yl)benzamido)propionate, ethanol, tin powder and concentrated hydrochloric acid into the reaction kettle , at a rotation speed of 200r / min and a temperature of 95°C, reflux reaction was carried out for 30 minutes, cooled to a temperature of 25°C, and sodium hydroxide solution was added until the pH value was 8 to obtain intermediate 2;

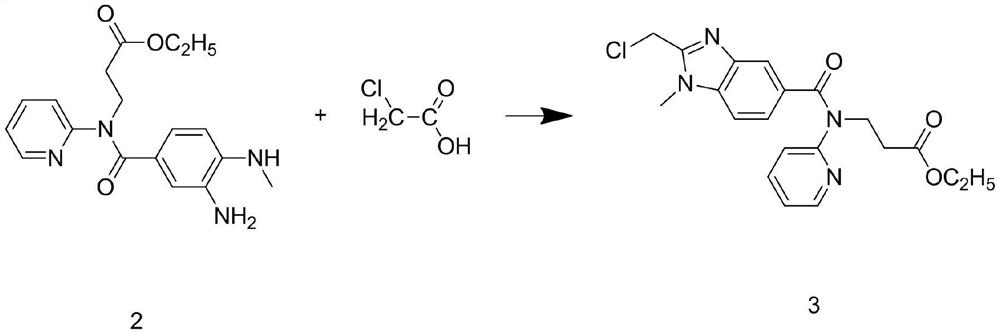

[0042]Step S3: Add chloroacetic acid to ethyl acetate, st...

Embodiment 2

[0046] A kind of dabigatran etexilate mesylate, is made by following steps:

[0047] Step S1: Add 4-aminobenzamidine dihydrochloride, toluene, triethylamine, and deionized water into the reaction kettle, stir for 13 minutes at a rotation speed of 250r / min and a temperature of 28°C, and then cool down At a temperature of 8°C, n-hexyl chloroformate was added dropwise at a rate of 0.15 L / h, and the reaction was carried out for 1.5 hours. At a temperature of 125°C, toluene and water were distilled off to obtain intermediate 1;

[0048] Step S2: Add ethyl 3-(4-(methylamino)-3-nitro-N-(pyridin-2-yl)benzamido)propionate, ethanol, tin powder and concentrated hydrochloric acid into the reaction kettle , at a rotation speed of 250r / min and a temperature of 98°C, reflux reaction was carried out for 35 minutes, cooled to a temperature of 28°C, and sodium hydroxide solution was added until the pH value was 8 to obtain intermediate 2;

[0049] Step S3: Add chloroacetic acid to ethyl acetat...

Embodiment 3

[0053] A kind of dabigatran etexilate mesylate, is made by following steps:

[0054] Step S1: Add 4-aminobenzamidine dihydrochloride, toluene, triethylamine, and deionized water into the reaction kettle, stir for 15 minutes at a rotation speed of 300r / min and a temperature of 30°C, and then cool down When the temperature is at 10°C, add n-hexyl chloroformate dropwise at a rate of 0.2 L / h, react for 1-2 hours, and at a temperature of 130°C, carry out distillation to remove toluene and water to obtain intermediate 1 ;

[0055] Step S2: Add ethyl 3-(4-(methylamino)-3-nitro-N-(pyridin-2-yl)benzamido)propionate, ethanol, tin powder and concentrated hydrochloric acid into the reaction kettle , at a rotation speed of 300r / min and a temperature of 100°C, reflux reaction was carried out for 40 minutes, cooled to a temperature of 30°C, and sodium hydroxide solution was added until the pH value was 9 to obtain intermediate 2;

[0056] Step S3: Add chloroacetic acid to ethyl acetate, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com