a kind of al 2 o 3 -b 2 o 3 -sio 2 Composite sol, activated carbon fiber with core-shell structure and preparation method thereof

A technology of activated carbon fiber and core-shell structure, applied in the field of activated carbon fiber, can solve the problem of low inherent strength of activated carbon fiber, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

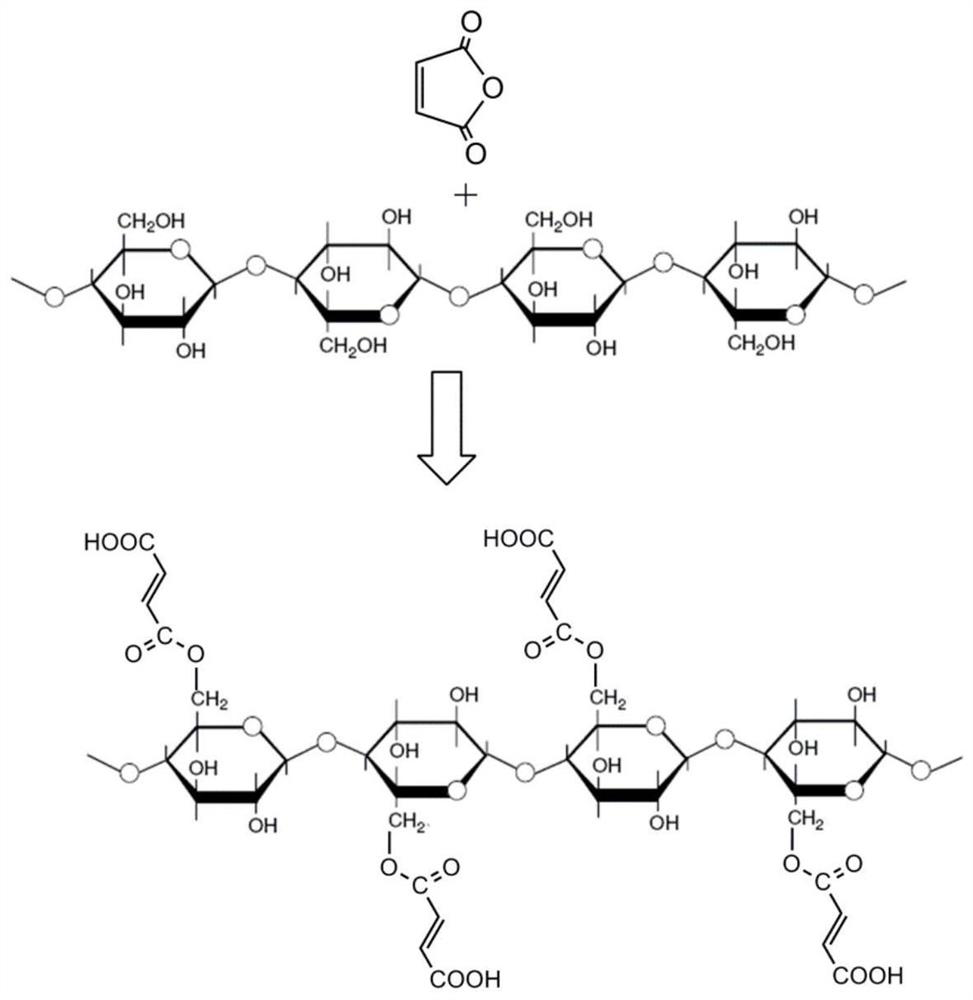

[0039] The preparation material of core-shell structure activated carbon fiber provided by the invention comprises: regenerated cellulose rayon, surface modification molecule maleic anhydride and Al 2 o 3 -B 2 o 3 -SiO 2 Composite sol mixture.

[0040] In the prior art, both maleic anhydride and polycarboxylic acid are used to modify the surface of cellulose fibers, mainly to anchor dye molecules. In this application, a maleic anhydride-modified surface was used to anchor Al 2 o 3 -B 2 o 3 -SiO 2 sol mixture shell, thus forming Al 2 o 3 -B 2 o 3 -SiO 2 The core-shell structure activated carbon fiber of composite oxide ceramic shell layer 1.

[0041] Raw materials of regenerated cellulose man-made fibers include: Lyocell fiber (textile industry standard FZ / T52019-2011), modal fiber (textile industry standard FZ / T 52043-2016), bamboo viscose fiber (textile industry standard FZ / T52043-2016), bamboo viscose fiber (textile industry standard Standard FZ / T 52006-2006),...

Embodiment 1

[0067] The invention provides a method for preparing activated carbon fibers with a core-shell structure, comprising the steps of:

[0068] Step 1. 10 g of regenerated cellulose fiber raw material is impregnated with an acetone solution with a mass concentration of maleic anhydride of 3%, so that the loading of maleic anhydride is 1.5% of the mass of the regenerated cellulose man-made fiber. Afterwards, the fiber raw material adsorbed maleic anhydride was heated to 80° C. for 60 minutes. The purpose of heat treatment was to accelerate the esterification reaction between maleic anhydride and hydroxyl groups on the fiber surface.

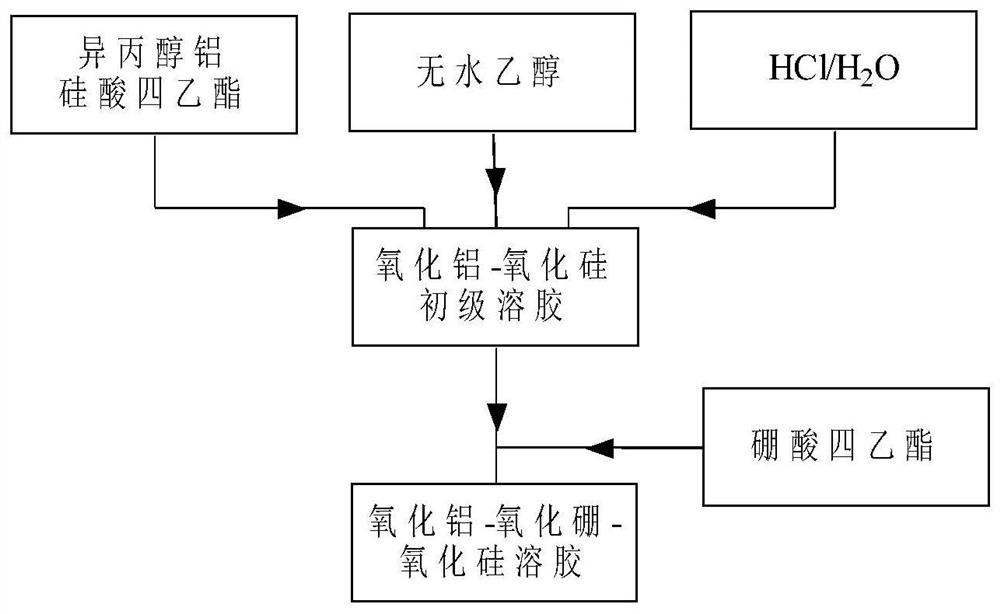

[0069] Step 2. Mix 12.25g (0.06mol) aluminum isopropoxide and 6.25g (0.03mol) tetraethyl silicate with 15.2g absolute ethanol evenly. Then add HCl (0.04g, 1.1mmol) / H 2 O (4.36g, 0.242mol), the mixture was stirred at room temperature for 20min to form an alumina-silica primary sol, then 2.92g (0.02mol) triethyl borate was added, and the mixture was he...

Embodiment 2

[0076] The invention provides a method for preparing activated carbon fibers with a core-shell structure, which is used to study Al 2 o 3 -B 2 o 3 -SiO 2 The influence of the aluminum-boron-silicon element ratio (as shown in Table 2) on the mechanical properties of the final core-shell structure activated carbon fiber in the composite sol specifically includes the following steps:

[0077] Step 1. 10 g of Lyocell fiber raw materials are impregnated with an acetone solution with a mass concentration of maleic anhydride of 3%, so that the loading of maleic anhydride is 1.5% of the mass of the regenerated cellulose rayon. Afterwards, the fiber raw material adsorbed maleic anhydride was heated to 80° C. for 60 minutes. The purpose of heat treatment was to accelerate the esterification reaction between maleic anhydride and hydroxyl groups on the fiber surface.

[0078] Step 2. Use Al 2 o 3 -B 2 o 3 -SiO 2 The total molar amount of the precursor raw materials composed of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com