Preparation method of high-purity white crystalline aluminum chloride

A technology for crystallizing aluminum chloride and aluminum chloride, which is applied in the direction of aluminum chloride and aluminum halide, can solve problems such as incapable of large-scale industrial production, achieve resource reuse, realize large-scale production, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

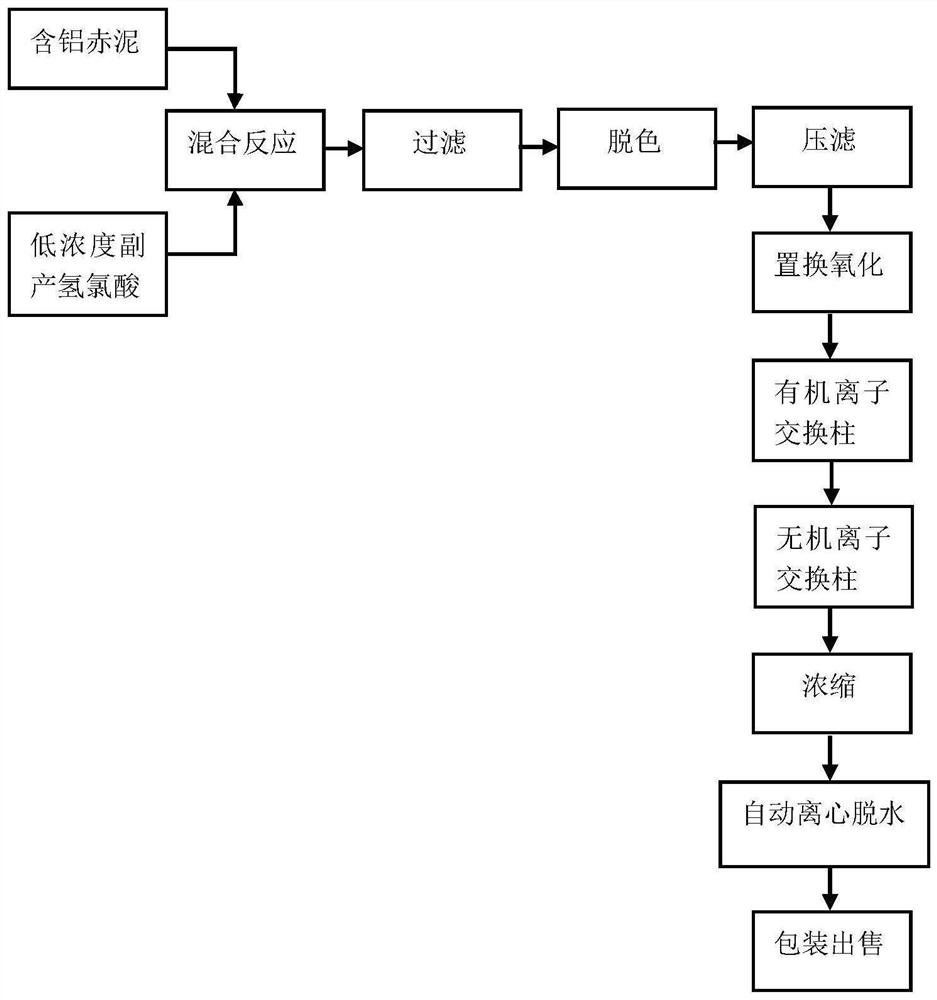

Image

Examples

Embodiment 1

[0016] S1. Add aluminum-containing red mud (the content of aluminum oxide in the aluminum-containing red mud is 10% by mass) as a by-product of chemical enterprises and metallurgical enterprises, add hydrochloric acid with a mass concentration of 20%, and mix and react to make an unsaturated solution of aluminum chloride , and then undergo filtration, dehydration, and filter press impurity removal processes to make the solution clear and transparent;

[0017] S2, add 1% by mass percentage of aluminum particles to the solution for replacement reaction, replace metals whose activity is lower than that of aluminum in the solution, then add 0.5% by mass of strong oxidizing agent to reduce the iron in the solution, and then remove organic matter by organic ion exchange resin Solvent; then remove iron through macroporous adsorption resin ion exchange column, exchange other metal ions (copper, magnesium, arsenic, etc.) High-purity aluminum chloride solution;

[0018] S3. Concentrate...

Embodiment 2

[0020] S1, the by-product aluminum-containing red mud of chemical enterprises and metallurgical enterprises (aluminum oxide content is 15% by mass in the aluminum-containing red mud), add the hydrochloric acid of concentration 25%, mix reaction and make aluminum chloride unsaturated solution, Then, after filtration, dehydration, and pressure filtration to remove impurities, the solution is clear and transparent;

[0021] S2, add 2% by mass percentage of aluminum chips to the solution for replacement reaction, replace metals with lower activity than aluminum in the solution, then add 1% by mass of strong oxidizing agent to reduce iron in the solution, and then remove organic Solvent; then remove iron through macroporous adsorption resin ion exchange column, exchange other metal ions (copper, magnesium, arsenic, etc.) High-purity aluminum chloride solution;

[0022] S3. Concentrate and crystallize the aluminum chloride solution, and then perform centrifugal dehydration with a f...

Embodiment 3

[0024] S1, the by-product aluminum-containing red mud of chemical enterprises and metallurgical enterprises (aluminum oxide content is 20% by mass in the aluminum-containing red mud), add the hydrochloric acid of concentration 25%, mixed reaction makes aluminum chloride unsaturated solution, Then, after filtration, dehydration, and pressure filtration to remove impurities, the solution is clear and transparent;

[0025] S2. Add 5% by mass of aluminum powder to the solution for substitution reaction, replace metals with lower activity than aluminum in the solution, then add 1% by mass of strong oxidizing agent to reduce iron in the solution, and then remove organic Solvent; then remove iron through macroporous adsorption resin ion exchange column, exchange other metal ions (copper, magnesium, arsenic, etc.) High-purity aluminum chloride solution;

[0026] S3. Concentrate and crystallize the aluminum chloride solution, and then use a fully automatic titanium twisted cage for ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com