Nano iron sulfide with dual functions of inhibiting bacteria and slowly releasing hydrogen sulfide as well as preparation method and application thereof

An iron sulfide and nanotechnology, applied in the field of nanomaterials, can solve the problems of product instability, poor biocompatibility, single antibacterial function, etc., and achieve the effects of stable properties, good dispersibility, and wound healing promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

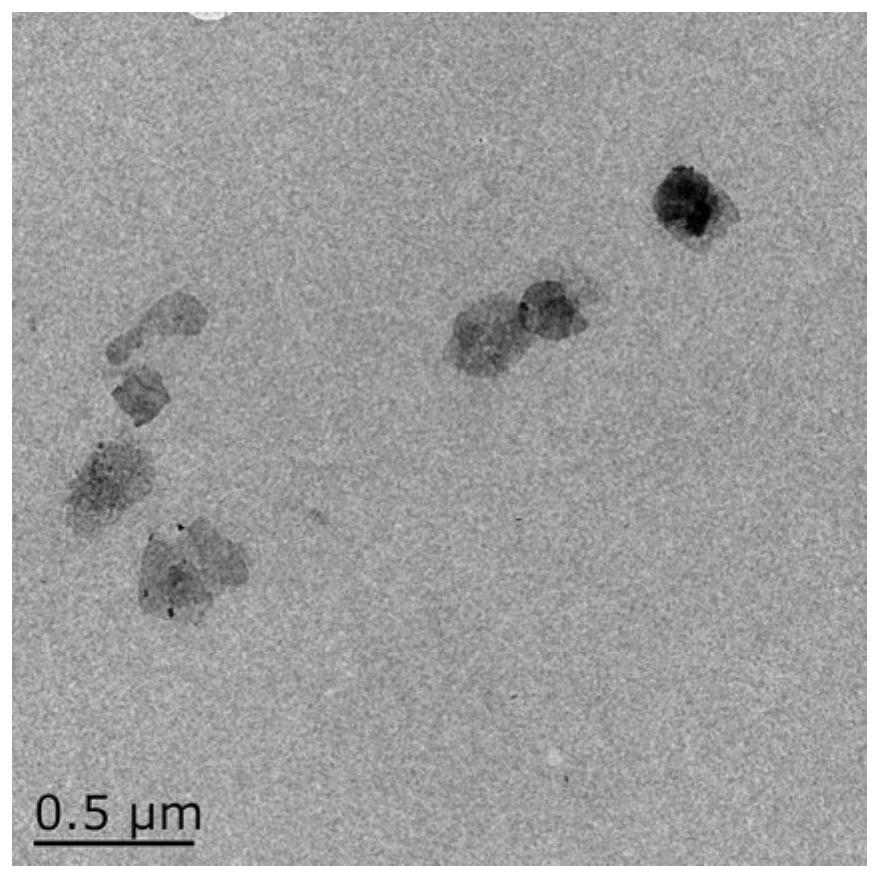

[0031] Preparation and characterization of nano-iron sulfide Example 1: Dissolve 0.5g of polyvinylpyrrolidone (molecular weight: 10,000) in 20mL of ethylene glycol, and add 0.2g of FeCl after fully dissolved 3 .6H 2 O, 3.6g of sodium acetate solution (0.1M, pH4.5), and 1g of L-cysteine, stirred evenly by magnetic force. All the reaction solution was poured into a 50 ml polytetrafluoroethylene reactor, transferred to an oven, and reacted at 200° C. for 16 hours. After the reaction product is naturally cooled to room temperature, it is centrifuged, washed three times with absolute ethanol, freeze-dried in a vacuum, and finally obtains nanometer iron sulfide. Scanning electron microscope (SEM), transmission electron microscope (TEM) characterizes product (see figure 1 ).

Embodiment 2

[0033] Preparation and characterization example 2 of nano-iron sulfide: Dissolve 1.0g of polyvinylpyrrolidone (molecular weight: 10,000) in 20mL of ethylene glycol, and add 0.2g of FeCl after fully dissolved 3 .6H 2 O, 3.6g of sodium acetate solution (0.1M, pH4.5), and 0.5g of L-cysteine, stirred evenly by magnetic force. All the reaction solution was poured into a 50 ml polytetrafluoroethylene reactor, transferred to an oven, and reacted at 200° C. for 24 hours. After the reaction product is naturally cooled to room temperature, it is centrifuged, washed three times with absolute ethanol, freeze-dried in a vacuum, and finally obtains nanometer iron sulfide.

Embodiment 3

[0035] Preparation and characterization of nano-iron sulfide Example 3: Dissolve 0.5g of polyvinylpyrrolidone (molecular weight: 10,000) in 20mL of ethylene glycol, and add 0.2g of FeCl after fully dissolved 3 .6H 2 O, 3.6g of sodium acetate solution (0.1M, pH4.5), and 1g of thiourea, stirred evenly by magnetic force. All the reaction solution was poured into a 50 ml polytetrafluoroethylene reactor, transferred to an oven, and reacted at 200° C. for 16 hours. After the reaction product is naturally cooled to room temperature, it is centrifuged, washed three times with absolute ethanol, freeze-dried in a vacuum, and finally obtains nanometer iron sulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com