Silicone polymer and its preparation method, adhesive and its application

An organosilicon compound and adhesive technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problem of poor storage stability, application limitations, slow initial curing speed of single-component dealcoholization, etc. problems, to achieve the effects of easy storage, improved initial bonding strength, and shortened packaging waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

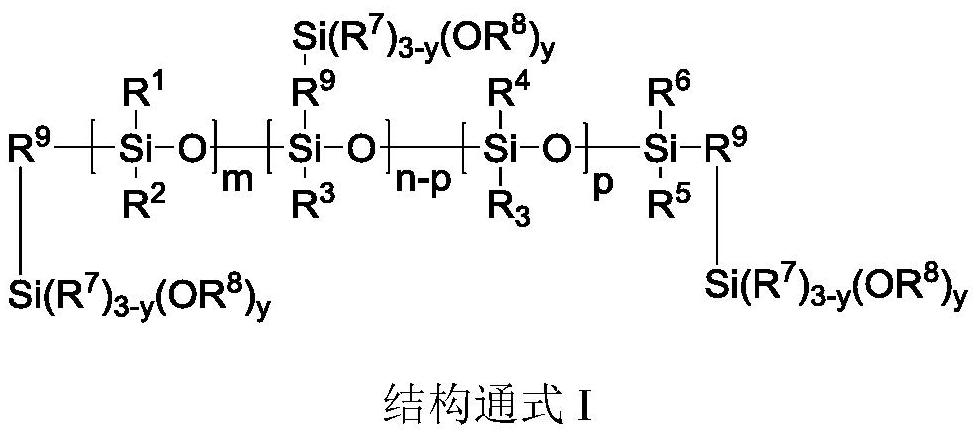

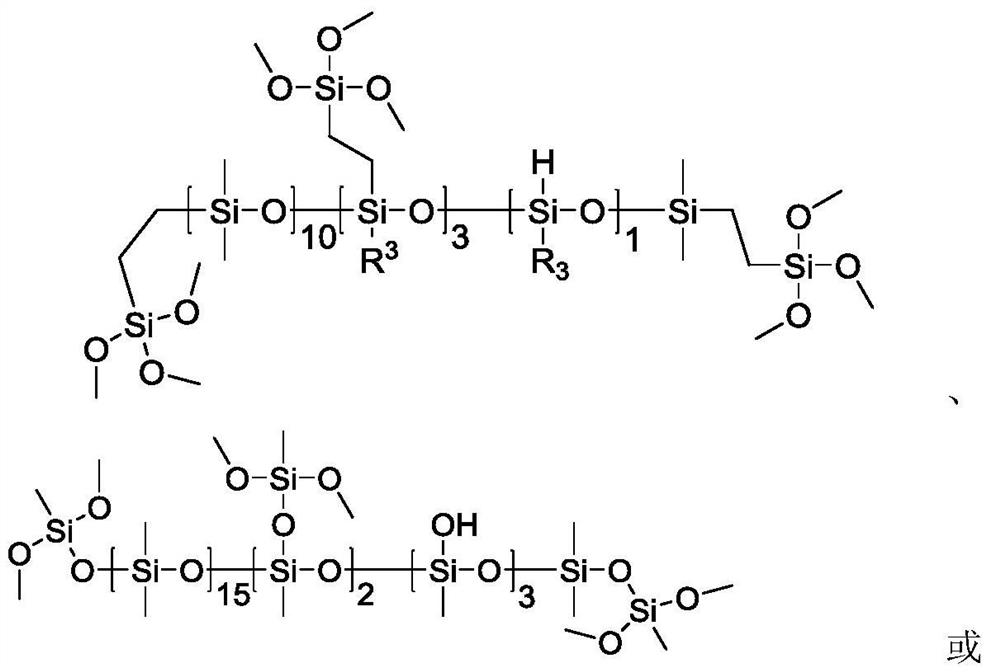

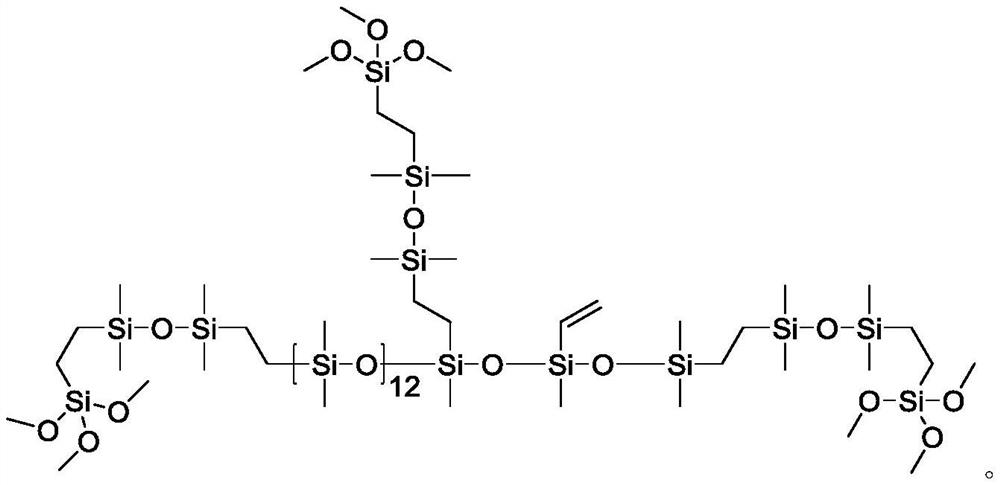

[0041] In another typical embodiment of the present application, a preparation method of the aforementioned organosilicon polymer is provided, characterized in that, the preparation method includes: step S1 , combining polysiloxane a with R 13 Si(R 7 ) 3-y (OR 8 ) y Carry out an addition reaction; or step S1', combine polysiloxane a with Si(R 7 ) 4-x (OR 8 ) x Condensation reaction is carried out under alkaline conditions to obtain the organosilicon polymer whose general structural formula is I; the general structural formula of above-mentioned polysiloxane a is as follows: where R 13 is H or vinyl, R 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 , R 8 , m, n, p, y, z are the same as R in the general formula I 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 , R 8 , m, n, p, y, z, in step S1, R 12 When H, R 4 is vinyl; R 12 When vinyl, R 4 is H; in step S1', R 4 is hydroxyl.

[0042]In order to facilitate those skilled in the art to synthesize the above-mentioned or...

Embodiment 1

[0057] Add 100 parts to a mixing vessel equipped with a stirring blade and the viscosity at 25°C is 3500mPa·s, the structural formula is (CH 2 =CH)[(CH 3 ) 2 SiO] 12 [(CH 2 =CH)(CH 3 )SiO] 2 Si(CH 3 ) 2 (CH=CH 2 ) of polydimethylsiloxane (vinyl content is 0.8wt%), 9 parts of trimethoxysilylethylenetetramethyldisiloxane, 0.01 part of platinum mass fraction of 0.7% platinum vinylsiloxane The oxane complex was stirred at 40 °C for 3 h to obtain the organosilicon polymer 1.

[0058] Put 100 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mpa·s at 25°C, 10 parts of dimethicone with a viscosity of 500mpa·s, and 100 parts of light calcium carbonate into the planetary agitator In the process, start stirring and dispersing, dehydrate at 120-140°C and -0.09--0.1MPa vacuum condition for 2-4 hours, and then cool down to below 50°C. Add 3.5 parts of methyltrimethoxysilane, add 3 parts of the above-mentioned silicone polymer 1, 3 parts of bis(ethyl acetoacetat...

Embodiment 2

[0060] Add 100 parts to a mixing vessel equipped with a stirring blade, the viscosity at 25°C is 300mPa·s, and the structural formula is (H)[(CH 3 ) 2 SiO] 10 [(CH 3 )(H)SiO] 4 Si(CH 3 ) 2 (H) polydimethylsiloxane (hydrogen content of 0.1 wt%), 16 parts of vinyltrimethoxysilane, 0.01 part of platinum-vinylsiloxane complex with a platinum mass fraction of 0.7%, in Stirring at 30-40°C for 2-3 h to obtain silicone polymer 2.

[0061] 100 parts of trimethoxysilane-terminated polydimethylsiloxane with a viscosity of 50,000 mpa·s at 25°C, 20 parts of dimethicone with a viscosity of 100 mpa·s, 80 parts of light calcium carbonate, and 80 parts of heavy calcium carbonate Put 40 parts into the planetary mixer, start stirring and dispersing, dehydrate at 120~140℃, -0.09~-0.1MPa vacuum condition for 2~4 hours, and then cool down to below 50℃. Add 3.5 parts of methyltrimethoxysilane, 1.5 parts of the above-mentioned organosilicon polymer 2, 3 parts of isopropyl titanate modified wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com