Outer-soft inner-rigid downstream face waterproof material and preparation method and application thereof

A technology that is soft on the outside and rigid on the inside, and a waterproof material. It is applied to building insulation materials, asphalt coatings, and building components. It can solve problems such as difficulties and achieve the effects of regulating the setting time, accelerating early hydration, and improving impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

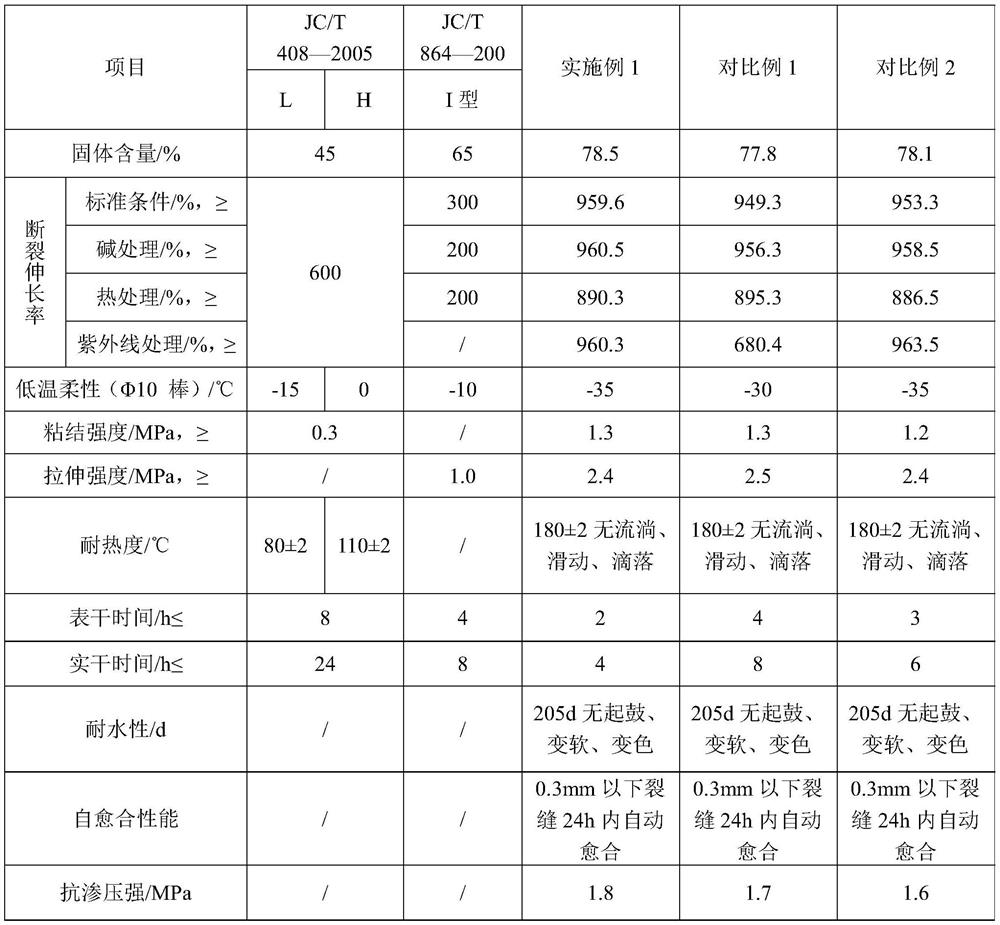

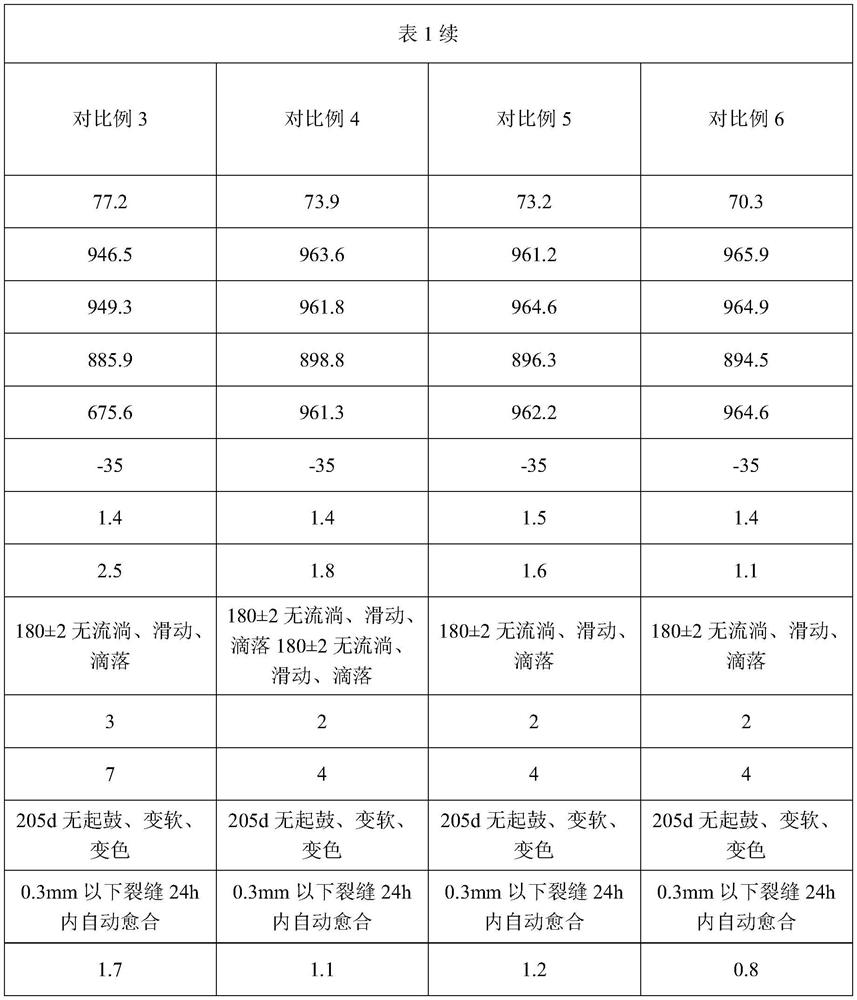

Examples

Embodiment 1

[0067]A water-proof material for the backwater surface that is soft on the outside and rigid on the inside, and the components are calculated by parts by weight:

[0068] Component A: 70 parts of anionic emulsified asphalt, 70 parts of acrylate emulsion, 1.75 parts of alkali-swellable thickener, 0.5 parts of polyurethane thickener, 1.25 parts of dispersant, 0.5 parts of pH regulator, 0.75 parts of defoamer, bactericidal 0.5 part of agent, 70 parts of heavy calcium carbonate powder, 30 parts of bentonite, 50 parts of organic silicon water-repellent agent with solid content of 25% sodium methyl silicate solution, 40 parts of solid content of 25% sodium silicate aqueous solution, photoinitiator 2 , 0.625 parts of 2-dimethoxy-phenylacetophenone, 0.574 parts of methyltrimethoxysilane as a crosslinking agent, and 45 parts of water.

[0069] Component B: 45 parts of sulfoaluminate cement, 6 parts of gypsum, 7.5 parts of silica fume, 25 parts of mineral powder, 7.5 parts of fly ash, 0...

Embodiment 2

[0072] Component A: 60 parts of cationic emulsified asphalt, 60 parts of acrylate emulsion, 1.5 parts of alkali-swellable thickener, 0.25 part of polyurethane thickener, 1.0 part of dispersant, 0.25 part of pH regulator, 0.5 part of defoamer, bactericidal 0.25 parts of agent, 60 parts of heavy calcium carbonate powder, 20 parts of bentonite, 40 parts of organosilicon water-repellent solid content 25% potassium methyl silicate solution, 30 parts of solid content 25% sodium silicate aqueous solution, photoinitiator 2 , 0.25 parts of 2-dimethoxy-phenylacetophenone, 0.25 parts of double-ended acrylamidopropylpolysiloxane as a crosslinking agent, and 40 parts of water.

[0073] Component B: 40 parts of sulfoaluminate cement, 5 parts of gypsum, 5 parts of silica fume, 20 parts of mineral powder, 5 parts of fly ash, 0.25 parts of citric acid, 2 parts of magnesium fluorosilicate, 5 parts of magnesium oxide, powder 2 parts of sodium silicate, 0.25 parts of reinforcing components, and 0...

Embodiment 3

[0076] Component A: 80 parts of non-ionic emulsified asphalt, 80 parts of acrylate emulsion, 2 parts of alkali-swellable thickener, 0.75 parts of polyurethane thickener, 1.5 parts of dispersant, 0.75 parts of pH regulator, 1.0 part of defoamer, 0.75 parts of bactericide, 80 parts of heavy calcium carbonate powder, 30 parts of bentonite, 50 parts of organic silicon water repellent with 25% solid content of sodium methyl silicate solution, 40 parts of solid content of 25% sodium silicate aqueous solution, photoinitiator 0.75 parts of 2,2-dimethoxy-phenylacetophenone, 0.75 parts of crosslinking agent methyltrimethoxysilane, and 50 parts of water.

[0077] Component B: 50 parts of sulfoaluminate cement, 7 parts of gypsum, 10 parts of silica fume, 30 parts of mineral powder, 10 parts of fly ash, 10 parts of citric acid, 5 parts of magnesium fluorosilicate, 10 parts of magnesium oxide, powder 5 parts of sodium silicate, 1 part of reinforcing component, and 1 part of fumed silica.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com