Uniform and high-strain two-dimensional molybdenum disulfide material and preparation method thereof

A molybdenum disulfide, high-strain technology, applied in the fields of molybdenum sulfide, chemical instruments and methods, polycrystalline material growth, etc., can solve the problems of unrealized potential, achieve easy large-scale preparation, enhance controllability and uniformity , the effect of strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

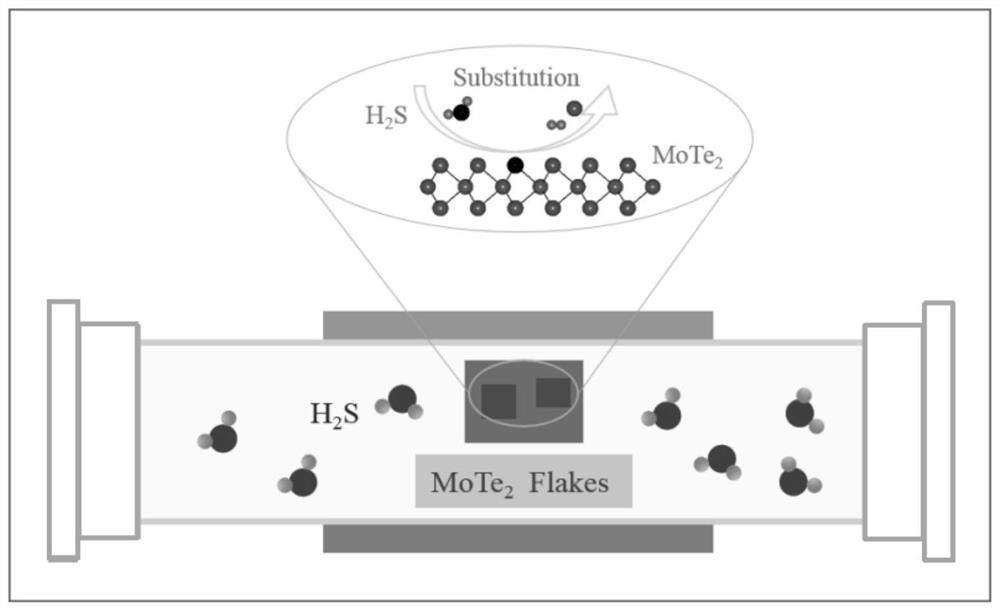

[0027] A method for preparing a uniform and high-strain two-dimensional molybdenum disulfide material provided in an embodiment of the present invention, adopts such as figure 1 The shown device is prepared, comprising the steps of:

[0028] Two-dimensional molybdenum ditelluride with the same crystal structure is used as a precursor, placed in a hydrogen sulfide atmosphere, and at a reaction temperature above 600°C, the controllable tellurium element is produced between molybdenum ditelluride and hydrogen sulfide and sulfur element replacement, thereby converting molybdenum ditelluride into two-dimensional molybdenum disulfide, such as Figure 7 As shown, since the lattice constant of molybdenum disulfide is 11.6% larger than that of molybdenum disulfide, molybdenum disulfide tends to maintain the lattice of molybdenum disulfide during the replacement process, so that the generated molybdenum disulfide maintains the strain.

[0029] Preferably, a mixed gas with a concentrati...

Embodiment 1

[0036] Two-dimensional molybdenum ditelluride with different thicknesses prepared by mechanical exfoliation method was transferred to a silicon oxide substrate and placed in a horizontal quartz tube; the quartz tube was flushed with argon, the air was exhausted, and then a sulfide solution with a concentration of 5% was introduced. The mixed gas of hydrogen and argon until the pressure in the quartz tube reaches 0.7 atmospheres; the quartz tube is closed, and heating is started, and the temperature is raised to 600 °C at a heating rate of 20 °C / min and then kept for 10 minutes; then the quartz tube is naturally cooled to room temperature, After absorbing hydrogen sulfide gas with sodium hydroxide solution, the sample was taken out to complete the preparation of two-dimensional molybdenum disulfide.

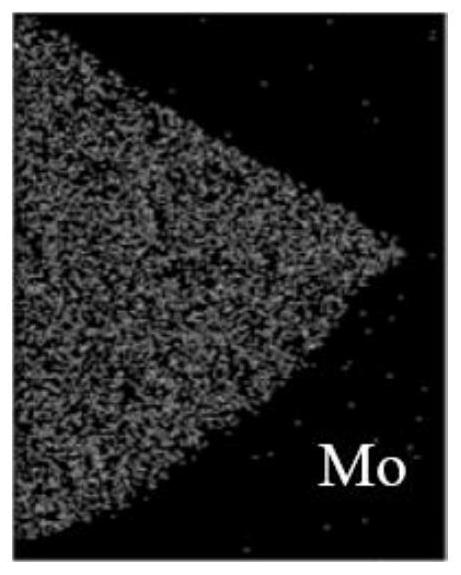

[0037] Elemental analysis (for tellurium, molybdenum, and sulfur, respectively) of partially replaced samples using energy-dispersive X-ray spectroscopy in a transmission electron ...

Embodiment 2

[0041]Two-dimensional molybdenum ditelluride with different thicknesses prepared by mechanical exfoliation method was transferred to a silicon oxide substrate and placed in a horizontal quartz tube; the quartz tube was flushed with argon, the air was exhausted, and then a sulfide solution with a concentration of 5% was introduced. The mixed gas of hydrogen and argon until the pressure in the quartz tube reaches 0.7 atmospheres; the quartz tube is closed, and heating is started, and the temperature is raised to 680 °C at a heating rate of 20 °C / min and then kept for 10 minutes; then the quartz tube is naturally cooled to room temperature, After absorbing hydrogen sulfide gas with sodium hydroxide solution, the sample was taken out to complete the preparation of two-dimensional molybdenum disulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com