Integrated skid-mounted complete device and treatment process thereof for treating sulfur-containing produced water of ultra-low permeability oil field

A technology of treatment process and complete set of equipment, which is applied in the field of integrated skid-mounted complete set of equipment for treatment of sulfur-containing produced water in ultra-low permeability oilfields and its treatment process, which can solve the problems of poor ground system support, difficult manual operation of treatment process, and scattered locations problems, to achieve the effect of compact integrated design, low labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

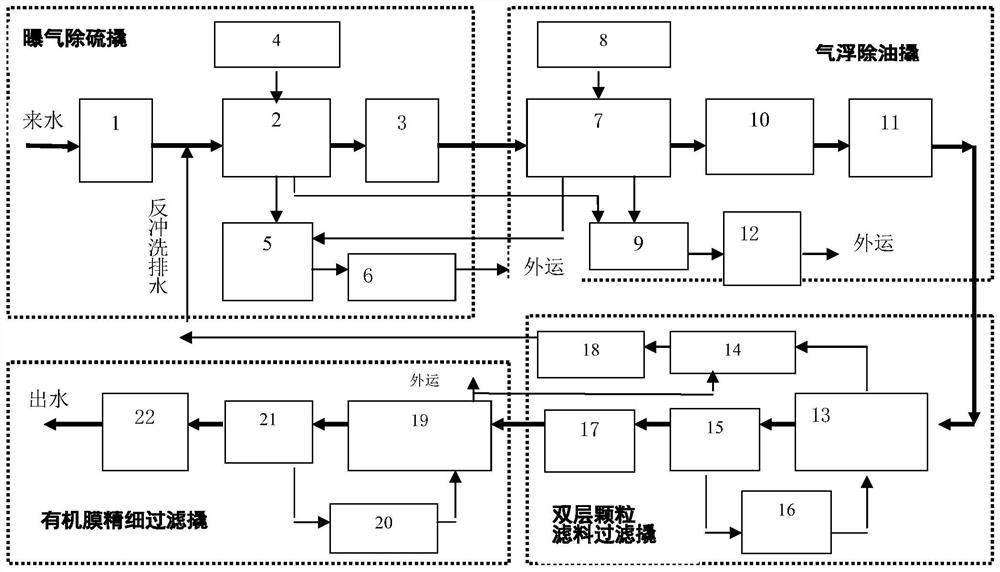

[0042] Such as figure 1 As shown, an integrated skid-mounted complete set of equipment for treatment of sulfur-containing produced water in ultra-low permeability oilfields is divided into four individual skids. The aeration and desulfurization skid includes: total incoming water lift pump 1, aeration and desulfurization tank 2. Air flotation lifting pump 3, Roots blower 4, dirty oil tank 5, dirty oil lifting pump 6; air flotation degreasing skid includes: dissolved air flotation device 7, dosing device 8, sludge tank 9, buffer water tank 10 , filter lift pump 11, sludge lift pump 12; double-layer particulate filter material filter skid includes: two-stage double-layer filter material filter device 13, recovery water tank 14, buffer water tank 15, backwash pump 16, membrane lift pump 17, Recycled water lifting pump 18; organic membrane fine filtration skid includes: membrane filter 19, membrane backwashing system 20, purified water tank 21, purified water lifting pump 22; The...

Embodiment 2

[0046] A process for treating sulfur-containing produced water from ultra-low permeability oilfields. The incoming water used in this example is the sulfur-containing produced water from the No. 10 Oil Production Plant of Daqing Oilfield. First, the water comes from the sewage settling tank of the oil station, and the water temperature is 28°C. pH is 7, treatment capacity is 9.7m 3 / h, oil content 269.6mg / L, suspended solids 124.3mg / L, median particle size 2.946μm, sulfide 43.5mg / L, incoming water enters aeration desulfurization tank 2 through lift pump 1, and Roots blower 4 passes through The silica gel aeration tube evenly distributes the air in the water body in the form of micro-bubbles. The ratio of sedimentation aeration gas to water: 7 / 1, plays a role in blowing off while oxygen oxidizes sulfur ions, and the purpose is to remove divalent sulfur ions in water , the floating oil on the top of the aeration desulfurization tank 2 flows into the dirty oil tank 5 by itself, a...

Embodiment 3

[0048] A process for treating sulfur-containing produced water from ultra-low permeability oilfields. The incoming water used in this example is the sulfur-containing and oily sewage from the No. 10 Oil Production Plant of Daqing Oilfield. First, the incoming water from the sewage settling tank of the oil station has a water temperature of 28°C. , pH is 7, treatment capacity is 11.5m3 / h, oil content is 270.8mg / L, suspended matter is 131.2mg / L, median particle size is 2.725μm, sulfide is 38.1mg / L, incoming water is aerated and desulfurized by lift pump 1 Tank 2 and Roots blower 4 distribute the air evenly in the form of micro-bubbles in the water body through the silica gel aeration tube. It is used to remove divalent sulfur ions in water, and the floating oil on the top of the aeration desulfurization tank 2 flows to the dirty oil tank 5 by itself, and the high and low liquid levels are set in the dirty oil tank 5, and the sewage oil lifting pump 6 is connected to the oil syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com