Standard brick preparation process and standard brick

A technology for preparing and standard bricks, which is applied in clay products, applications, household appliances, etc., can solve the problems that the performance cannot reach the level of fired bricks, the environmental pressure and economic pressure are high, and it is not suitable for large-scale promotion and application. Good physical and mechanical properties, reducing the emission of solid particles, and improving the effect of high temperature resistance and air flow erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0047] Embodiment 1-3 all relates to a kind of standard brick preparation process, and concrete process step is as follows:

[0048] 1. Preparation of brick mixture

[0049] ⑴ Crushing of cinder, dry sludge and construction waste

[0050]First, crush cinders, dry sludge and construction waste, wherein the dry sludge is obtained from sewage treatment sludge after roasting at 500°C and cooling down. Construction waste can be waste concrete, waste mortar or a mixture of the two. Examples 1-3 All of them are waste concrete.

[0051] The crushing is divided into two stages. First, the jaw crusher is used for crushing, and the particle size after crushing is controlled at ≤20mm; then it is sent to the high-speed crusher for the second crushing, and after fine crushing, it passes through a 14-mesh sieve, and the particle size is controlled at ≤1.5mm .

[0052] ⑵ Mixing of raw materials

[0053] Weighing the crushed cinder, dry sludge and waste concrete according to the ratio, sen...

Embodiment 4-6

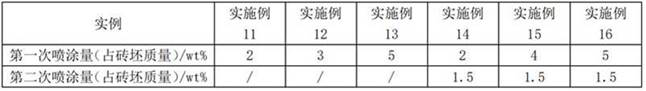

[0083] Embodiments 4-6 all relate to a standard brick preparation process, and are all based on Embodiment 2. The difference from Embodiment 2 is only in the specific process operation of the "spraying treatment liquid-drying" step, which is as follows:

[0084] Spray evenly the surface treatment solution accounting for 1-5wt% of the mass of the brick on the surface of the brick, and then send the brick to the drying room for drying at 70-90°C; again evenly spray the surface treatment of 1-2wt% on the surface of the brick liquid, and then dried at 70-90°C to obtain dried bricks.

[0085] The same surface treatment fluid was used for the two sprays. Specifically, the formula and spraying amount of the spray treatment liquid used in Examples 4-6 are shown in Table 3.

[0086] Table 3. Spray treatment liquid component distribution ratio and spray treatment liquid spray amount table in embodiment 4-6

[0087]

[0088] The inorganic mineral powder in Table 3 is made by mixing ...

Embodiment 7-10

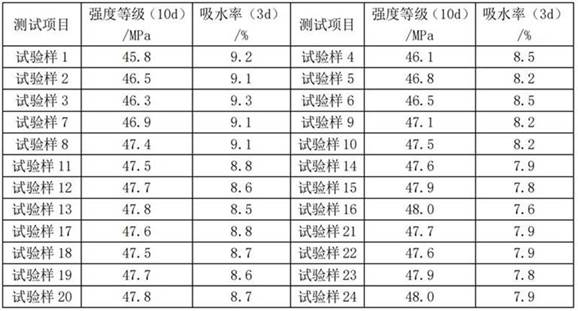

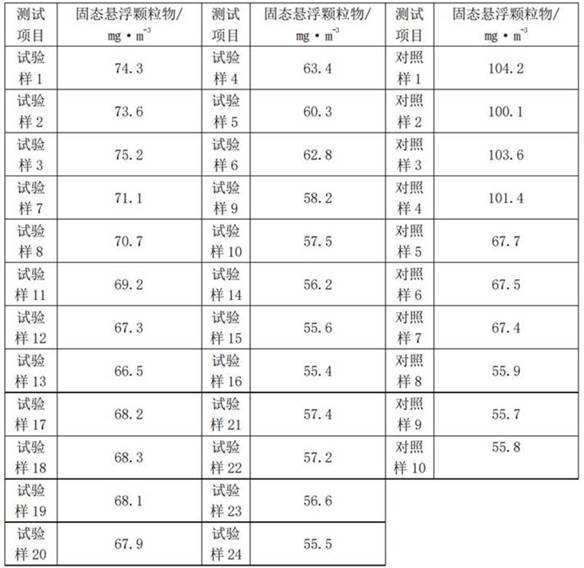

[0091] Examples 7-8 all relate to a standard brick preparation process, all of which are based on Example 2, and differ from Example 2 only in that the raw material formula of the standard bricks is different, see Table 4 for details.

[0092] Examples 9-10 all relate to a standard brick preparation process, all of which are based on Example 5, and differ from Example 5 only in that the raw material formula of the standard bricks is different, see Table 4 for details.

[0093] Table 4. Standard brick raw material matching table in embodiment 7-10

[0094]

[0095] The glass fiber powders used in Examples 7-10 were all purchased from Sarn Chemical Technology (Shanghai) Co., Ltd., with a specification of 9-13 μM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com