Standard brick preparation process and standard brick

A technology for preparing process, standard brick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

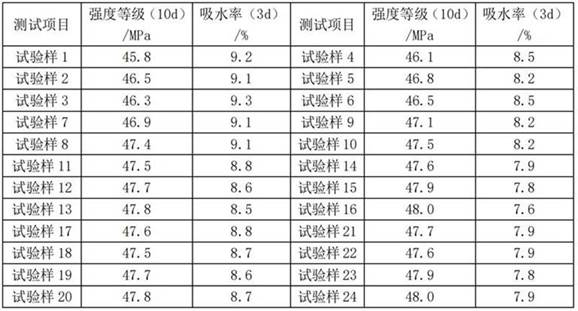

Embodiment 1-3

[0047] Embodiment 1-3 all relates to a kind of standard brick preparation process, and concrete process step is as follows:

[0048] 1. Preparation of brick mixture

[0049] ⑴Crushing of cinder, dry sludge and construction waste

[0050]First, crush cinders, dry sludge and construction waste, wherein the dry sludge is obtained from sewage treatment sludge after roasting at 500°C and cooling down. Construction waste can be waste concrete, waste mortar or a mixture of the two. Examples 1-3 All of them are waste concrete.

[0051] The crushing is divided into two stages. First, the jaw crusher is used for crushing, and the particle size after crushing is controlled at ≤20mm; then it is sent to the high-speed crusher for the second crushing, and after fine crushing, it passes through a 14-mesh sieve, and the particle size is controlled at ≤1.5mm .

[0052] ⑵ Mixing of raw materials

[0053] Weighing the crushed cinder, dry sludge and waste concrete according to the ratio, send...

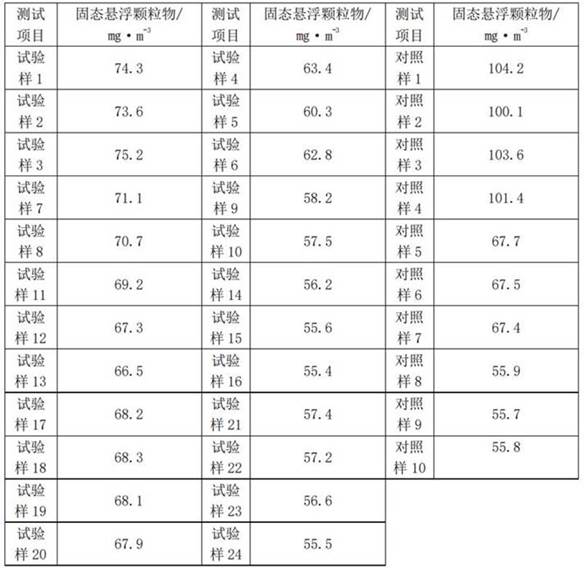

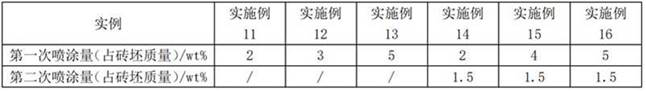

Embodiment 4-6

[0083] Embodiments 4-6 all relate to a standard brick preparation process, and are all based on Embodiment 2. The difference from Embodiment 2 is only in the specific process operation of the "spraying treatment liquid-drying" step, which is as follows:

[0084] Spray evenly the surface treatment solution accounting for 1-5wt% of the mass of the brick on the surface of the brick, and then send the brick to the drying room for drying at 70-90°C; again evenly spray the surface treatment of 1-2wt% on the surface of the brick liquid, and then dried at 70-90°C to obtain dried bricks.

[0085] The same surface treatment fluid was used for the two sprays. Specifically, the formula and spraying amount of the spray treatment liquid used in Examples 4-6 are shown in Table 3.

[0086] Table 3. Spray treatment liquid component distribution ratio and spray treatment liquid spray amount table in embodiment 4-6

[0087]

[0088] The inorganic mineral powder in Table 3 is made by mixing ...

Embodiment 7-10

[0091] Examples 7-8 all relate to a standard brick preparation process, all of which are based on Example 2, and differ from Example 2 only in that the raw material formula of the standard bricks is different, see Table 4 for details.

[0092] Examples 9-10 all relate to a standard brick preparation process, all of which are based on Example 5, and differ from Example 5 only in that the raw material formula of the standard bricks is different, see Table 4 for details.

[0093] Table 4. Standard brick raw material matching table in embodiment 7-10

[0094]

[0095] The glass fiber powders used in Examples 7-10 were all purchased from Sarn Chemical Technology (Shanghai) Co., Ltd., with a specification of 9-13 μM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com