Ultrathin micro-heat pipe with micro-channel capillary structure and preparation method thereof

A technology of capillary structure and microchannel, which is applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve problems such as difficult to use directly, and achieve the effect of avoiding small cavity diameter and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

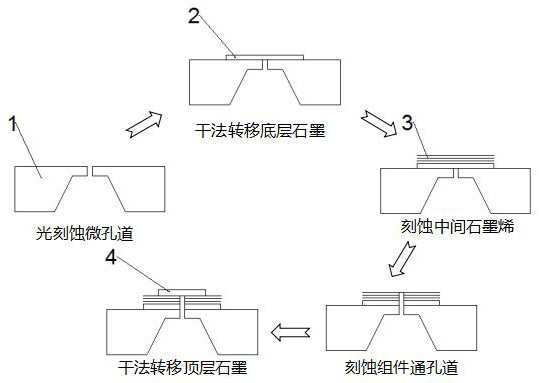

[0031] The preparation method steps are as follows:

[0032] Step a: using standard photolithography and reactive ion etching to etch a micron-scale rectangular channel in the middle of the silicon nitride wafer of the silicon nitride substrate 1 with a thickness of 90-120 μm;

[0033] Step b: Cover the channel obtained in step a with a layer of graphite with a thickness of 8-15 nm by dry transfer, which is marked as bottom graphite 2;

[0034] Step c: covering the bottom graphite 2 with graphene containing different layers and etched into equidistant strips by electron beam lithography and oxygen plasma, marking it as the middle layer graphene 3, and then covering it with dry transfer method The bottom graphite 2 surface and the long sides of the graphene are arranged vertically with the microchannels;

[0035] Step d: using the oxygen reactive ion etching process in step a to etch away the overlapped part of the bottom layer graphite 2 and the middle layer graphene 3 with t...

Embodiment 1

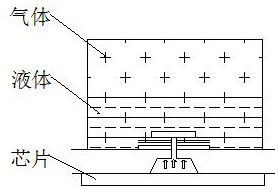

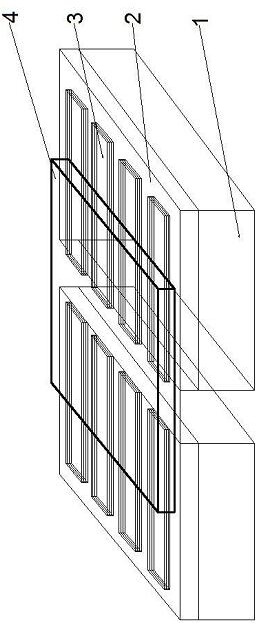

[0045] to combine figure 1 , the micro heat pipe capillary structure of the present invention comprises a silicon nitride substrate 1, a bottom graphite 2 arranged on a silicon nitride substrate 1, an intermediate layer of graphene 3 and a top layer of graphite 4, wherein the silicon nitride substrate 1 , the bottom layer of graphite 2 and the middle layer of graphene 3 have a microchannel structure with a width of 3 μm.

[0046] The preparation process of the micro heat pipe microchannel capillary structure of the present invention is as follows:

[0047] (1) Clean the silicon nitride wafer with a thickness of 100 μm in sequence with acetone, ethanol and deionized water, blow it dry with nitrogen and put it in an oven for 5 minutes; spin-coat photoresist on the surface of the silicon nitride wafer and put it in an oven at 100°C for drying Bake for 10 minutes; place a mask plate with 3×20 μm rectangular micro-holes on the silicon nitride wafer coated with photoresist, after c...

Embodiment 2

[0054] to combine figure 1 , the micro heat pipe capillary structure of the present invention comprises a silicon nitride substrate 1, a bottom graphite 2 arranged on a silicon nitride substrate 1, an intermediate layer of graphene 3 and a top layer of graphite 4, wherein the silicon nitride substrate 1 , the bottom layer of graphite 2 and the middle layer of graphene 3 have a microchannel structure with a width of 5 μm.

[0055] The preparation process of the micro heat pipe microchannel capillary structure of the present invention is as follows:

[0056] (1) Clean the silicon nitride wafer with a thickness of 100 μm in sequence with acetone, ethanol and deionized water, blow it dry with nitrogen and put it in an oven for 5 minutes; spin-coat photoresist on the surface of the silicon nitride wafer and put it in an oven at 100°C for drying Bake for 10 minutes; place a mask plate with 4×20 μm rectangular microholes on the silicon nitride wafer coated with photoresist, after ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com