Composite material laminated board and preparation method thereof

A technology of composite material layer and composite substrate, which is applied in the field of building decoration materials, can solve problems such as inability to directly bond with thermosetting resins, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

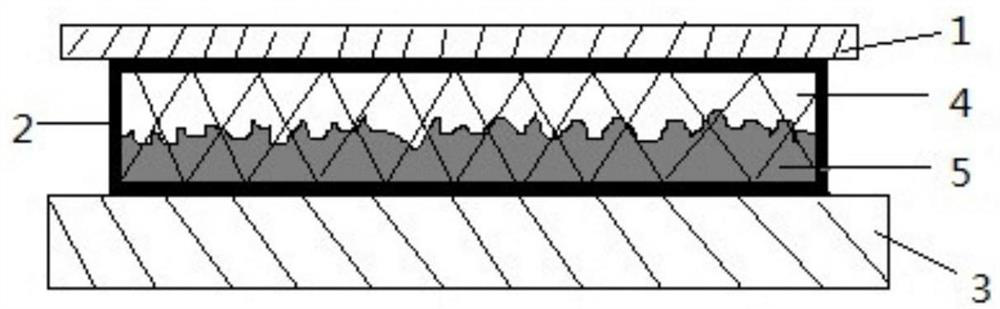

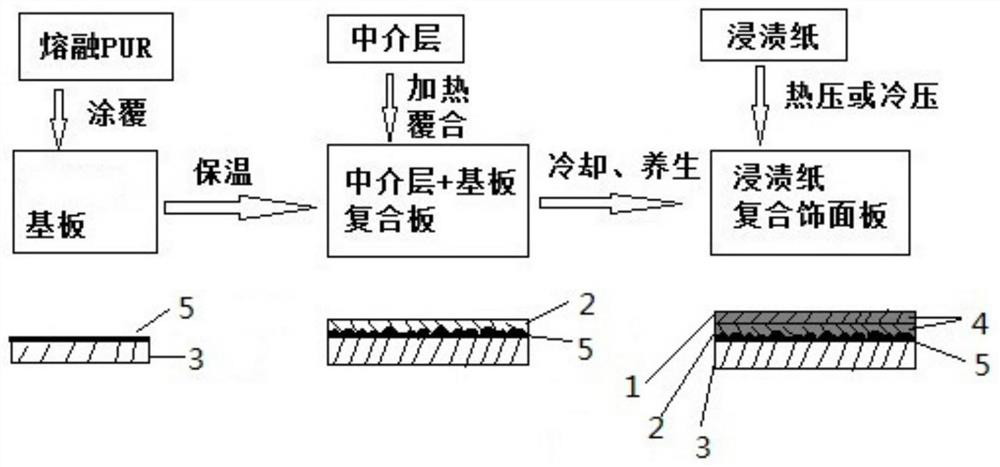

[0023] The composite laminate structure of the present embodiment is as figure 1 As shown, the impregnated paper layer 1 comprising the cured melamine formaldehyde resin impregnated on the upper layer, and the intermediate layer sheet 2 located in the middle have a gram paper weight of 20-40g / m 2 The base paper and the substrate 3 located in the lower layer are SPC sheets (boards extruded with PVC resin as the base material and calcium carbonate as filler). The sizing amount of impregnated paper impregnated with melamine formaldehyde resin is more than 130%, and the volatile matter is more than 6.0%. PVC resin in SPC substrate: calcium carbonate (weight ratio) is 1:3. There is a PUR hot-melt adhesive layer between the interposer sheet and the substrate. The interposer sheet is a fiber that can be penetrated and wetted by molten PUR hot-melt adhesive and thermosetting resin. The thermosetting resin 4 is penetrated and cured near the impregnated paper layer. The substrate laye...

Embodiment 2

[0027] The structure and preparation method of this embodiment are the same as those of the first embodiment, except that the substrate material can be replaced by a substrate WPC which is a mixture of PVC and wood flour in different proportions. Inorganic gel materials (such as silicate, gypsum, etc.) can also be used as substrates, and substrates made of other fillers (which can be wood fibers) are added. This kind of substrate has good heat resistance. In the second step, the low-pressure short-cycle lamination method can be used, that is, the lamination can be realized within 1 minute of the hot-pressing temperature at a hot-pressing temperature of 160-190°C. The laminate produced was of the same quality as Example 1.

Embodiment 3

[0029] The structure and preparation method of this embodiment are the same as those of Embodiment 1, except that the interlayer sheet material used is made of wood fiber, plant fiber or glass fiber, etc., which can be infiltrated and compatible with PUR hot melt adhesive and thermosetting resin respectively. The material is prepared as a thin sheet with a thickness of less than 2 mm. Such as other types of paper, wood veneer, glass fiber cloth, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com