Preparation method and photocatalysis effect of La0.7Sr0.3MnO3/alpha-Fe2O3

A -fe2o3, accurate technology, applied in the field of preparation of La0.7Sr0.3MnO3/α-Fe2O3 and its photocatalysis, can solve the problems of unsatisfactory photocatalysis effect, high recombination rate of photogenerated electrons and holes, and difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is realized through the following examples, but the conditions and results described in the implementation do not limit the content and rights of the invention.

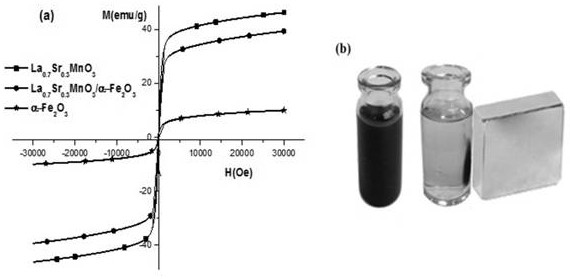

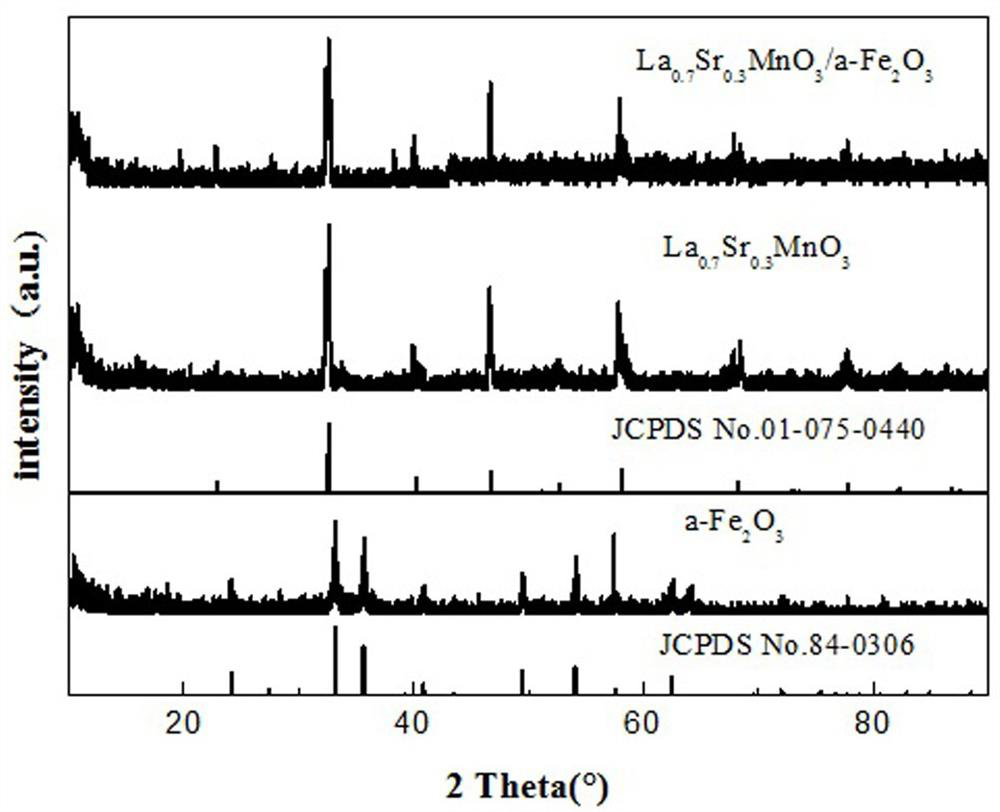

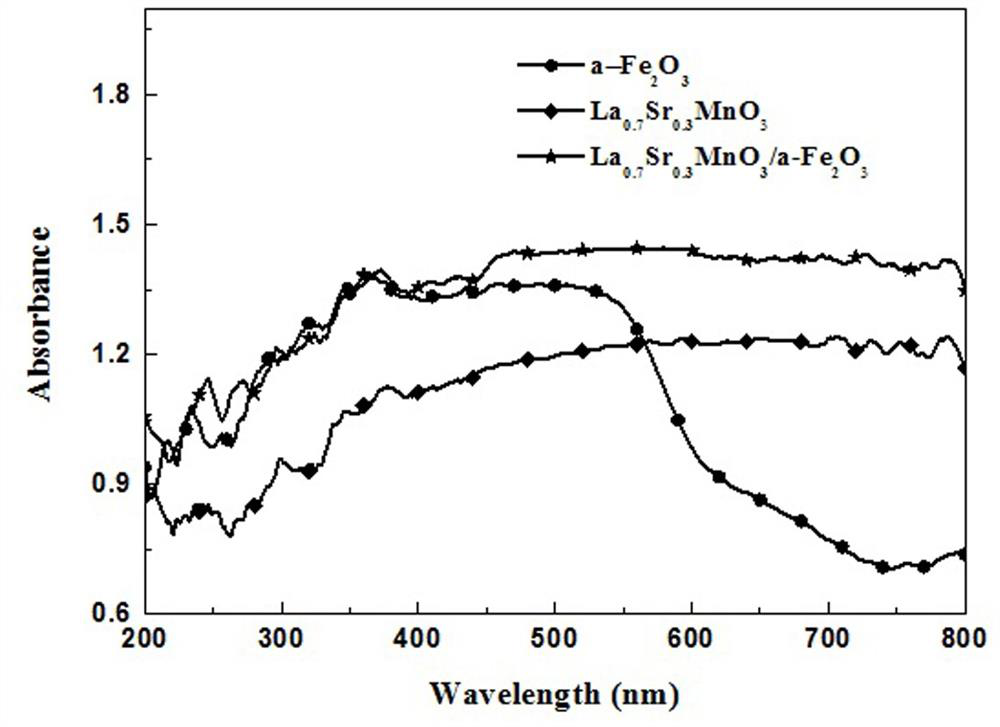

[0022] 1. p-n heterojunction magnetic composite oxide La 0.7 Sr 0.3 MnO 3 / α-Fe 2 o 3 preparation

[0023] 1.1 La 0.7 Sr 0.3 MnO 3-δ Preparation: Accurately weigh lanthanum acetate, strontium acetate, and manganese acetate so that the molar ratio is 0.7:0.3:1, dissolve the weighed reactants in water five times the amount, and after complete dissolution, hydrolyze at 80°C , as the solvent water evaporates to a paste, add absolute ethanol to dehydrate and evaporate to dryness, then place it in a muffle furnace, gradually heat it up to 800°C and calcined for 1.5h to obtain La 0.7 Sr 0.3 MnO 3-δ Powder;

[0024] 1.2 p-n heterojunction La 0.7 Sr 0.3 MnO 3 / α-Fe 2 o 3 Preparation: Take 2.0 mmol of Fe(NO 3 ) 3 .9H 2 O was dissolved in 20.0ml of absolute ethanol to obtain ferri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com