Preparation method of Gd < 3 + > doped BiOBr photocatalytic material

A photocatalytic material, the technology of cetyl trimethyl ammonium bromide, is applied in the field of preparation of BiOBr photocatalytic materials, and achieves the effects of simple method, avoiding a large reduction in photocatalytic efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

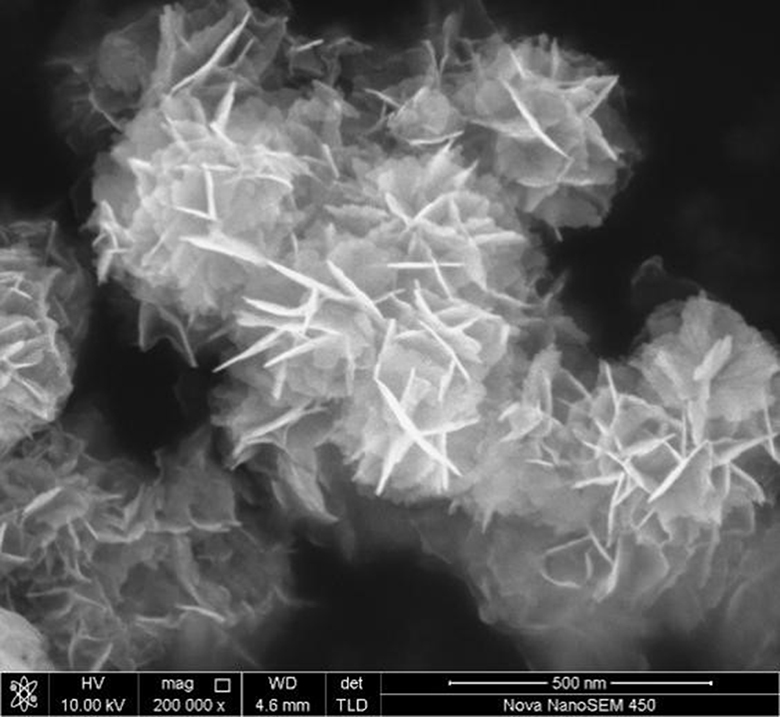

Image

Examples

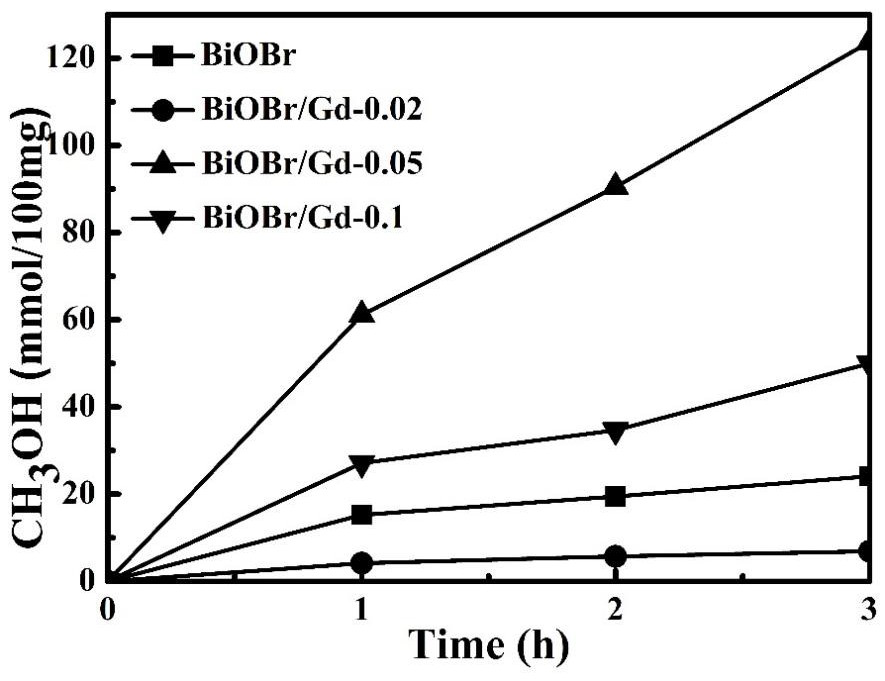

Embodiment 1

[0027] BiOBr / Gd composites were prepared according to the following steps:

[0028] (1) Weigh 1.45g cetyltrimethylammonium bromide and put it into boiled 18ml ethylene glycol as solution A, weigh 1.9414g bismuth nitrate pentahydrate and add it to 12ml glycerol, then add 0.036 g hydrated nitric acid solution, as solution B. Both solution A and solution B were stirred for 30 minutes, then solution B was slowly added dropwise to the beaker containing solution A, and the mixture of the two solutions was ultrasonically treated for 30 minutes to obtain a suspension;

[0029] (2) Transfer the suspension obtained in step (1) to a 50ml steel reaction kettle, put the reaction kettle in an oven, and heat the oven to 160 degrees Celsius for 12 hours;

[0030] (3) Transfer the reaction solution obtained in step (2) to a 50ml centrifuge tube, centrifuge to obtain the precipitate, and wash with deionized water and absolute ethanol three times respectively;

[0031] (4) Put the precipitate ...

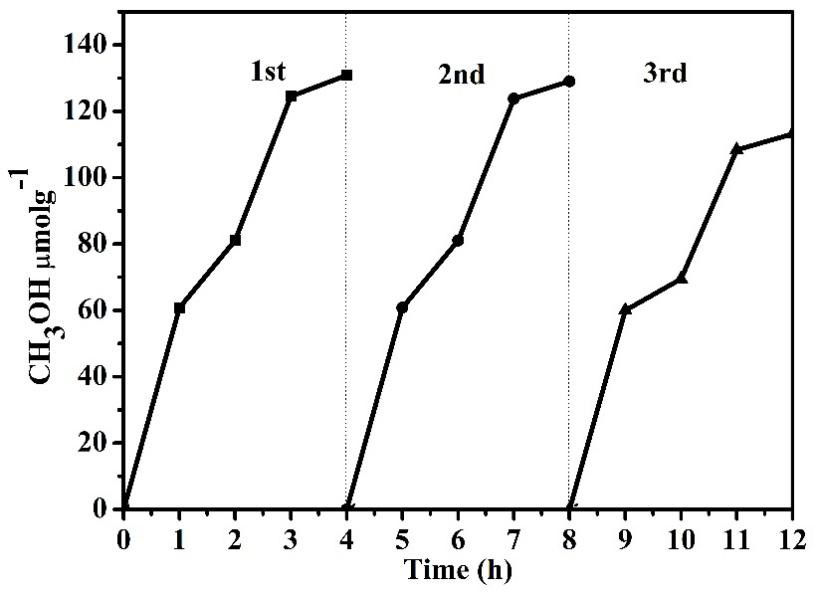

Embodiment 2

[0033] Gd / BiOBr composites were prepared according to the following steps:

[0034] (1) Weigh 1.45g of cetyltrimethylammonium bromide and put it into boiled 18ml of ethylene glycol as solution A, weigh 1.9414g of bismuth nitrate pentahydrate and add it to 12ml of glycerol, then add 0.090 g of hydrated nitric acid was used as solution B. Both solution A and solution B were stirred for 30 minutes, then solution B was slowly added dropwise to the beaker containing solution A, and the mixture of the two solutions was ultrasonically treated for 30 minutes;

[0035] (2) Transfer the suspension obtained in step (1) to a 50ml steel reaction kettle, put the reaction kettle in an oven, and heat the oven to 160 degrees Celsius for 12 hours;

[0036] (3) Transfer the reaction solution obtained in step (2) to a 50ml centrifuge tube, centrifuge to obtain the precipitate, and wash with deionized water and absolute ethanol three times respectively;

[0037] (4) Put the precipitate obtained ...

Embodiment 3

[0039] Gd / BiOBr composites were prepared according to the following steps:

[0040] (1) Weigh 1.45g of cetyltrimethylammonium bromide and put it into boiled 18ml of ethylene glycol as solution A, weigh 1.9414g of bismuth nitrate pentahydrate and add it to 12ml of glycerol, then add 0.18 g of hydrated nitric acid was used as solution B. Both solution A and solution B were stirred for 30 minutes, then solution B was slowly added dropwise to the beaker containing solution A, and the mixture of the two solutions was ultrasonically treated for 30 minutes;

[0041] (2) Transfer the suspension obtained in step (1) to a 50ml steel reaction kettle, put the reaction kettle in an oven, and heat the oven to 160 degrees Celsius for 12 hours;

[0042] (3) Transfer the suspension obtained in step (2) to a 50ml centrifuge tube, centrifuge to obtain the precipitate, and wash with deionized water and absolute ethanol three times respectively;

[0043] (4) Put the precipitate obtained after wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com