Preparation method of refined-TiC-particle-enhanced titanium-based composite material

A titanium-based composite material and particle reinforcement technology, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc. Controlled effect of applied pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

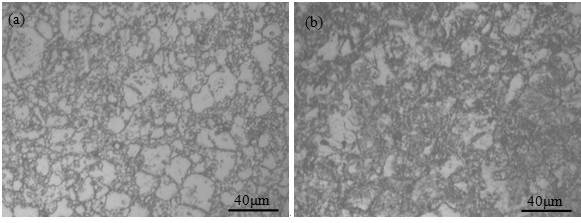

[0024] Embodiment 1: A kind of method of refinement TiC particle reinforced titanium-based composite material in this embodiment is carried out according to the following steps:

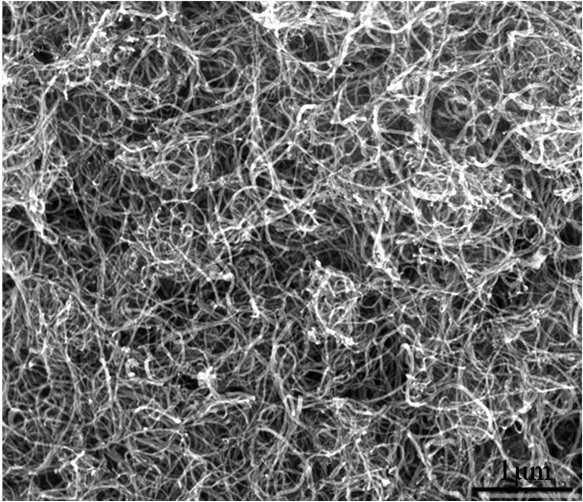

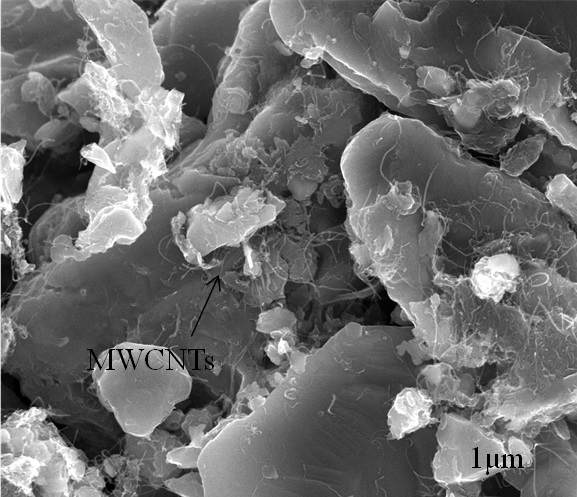

[0025] Step 1. Insulate 1g of carbon nanotubes at 300°C for 1h, cool to room temperature, take out, add 30ml of concentrated nitric acid, place in a hydrothermal reaction kettle, react at 150°C for 1h, cool to room temperature, take out, wash until neutral, and place in a vacuum Dry in a drying oven at 80°C for 6h.

[0026] Step 2: According to the weight ratio Ti:CNTs=98.5:1.5, add 40g of powder into the nodular ink tank, the ratio of ball to material is 1:5, the speed is 300r / min, add 30ml of absolute ethanol as the ball milling medium and mill for 4 hours, then use a vacuum of 60°C Dry in a drying oven for 10 hours, and then sieve through a 200-mesh sieve.

[0027] Step 3. Put the composite powder obtained in step 2 into a graphite mold of φ20×12, and obtain carbon nanotubes at a heating rate of ...

Embodiment 2

[0029] Embodiment 2: A kind of method of refinement TiC particle reinforced titanium-based composite material in this embodiment is carried out according to the following steps:

[0030] Step 1. Insulate 1g of carbon nanotubes at 400°C for 1h, cool to room temperature, take out, add 40ml of concentrated nitric acid and place in a hydrothermal reaction kettle, react at 180°C for 1h, cool to room temperature, take out, wash until neutral, and Dry in a vacuum oven at 80 °C for 6 h.

[0031] Step 2: According to the weight ratio Ti:CNTs=98.5:1.5, add 40g of powder into the nodular ink tank, the ratio of ball to material is 1:5, the speed is 200r / min, add 30ml of absolute ethanol as the ball milling medium and ball mill for 6h, then use a vacuum at 60°C Dry in a drying oven for 10 hours, and then sieve through a 200-mesh sieve.

[0032] Step 3. Put the composite powder obtained in step 2 into a graphite mold of φ20×12, and obtain carbon nanotubes at a heating rate of 100°C / min, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com