Method for preparing chloramphenicol

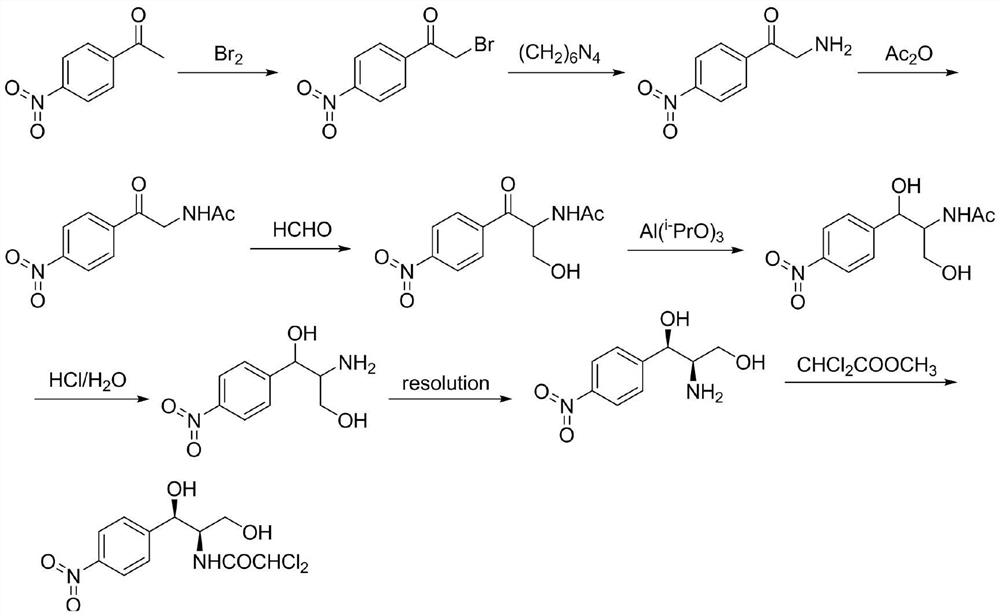

A technology of chloramphenicol and coenzyme, which is applied in the field of preparation of chloramphenicol, can solve the problems of high environmental hazards, cumbersome disassembly steps, and increased reaction steps, and achieve the effects of cost reduction, mild conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

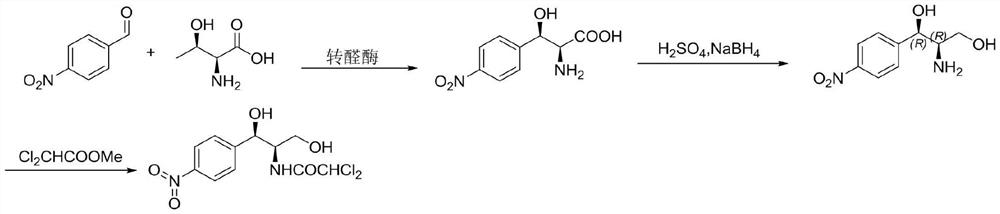

[0029] Embodiment 1: transaldolase catalyzed preparation of amino acid

[0030] Add 10g of p-nitrobenzaldehyde, 10g of L-threonine, 40mg of pyridoxal phosphate, 300mL of 100mM phosphate buffer (pH7.5) into a 500mL reaction bottle and heat to 30°C with magnetic stirring, then add 1g of transaldolase Enzyme powder (purchased from Suzhou Pilot Biotechnology Co., Ltd., product number is YH1062, here only provides one of the models of products to illustrate the effect of the present invention), start stirring reaction, after 20 hours, sampling HPLC detects that the conversion rate is 90% above. After the reaction was completed, the white solid was collected by filtration, and the white solid product was recrystallized with ethanol to obtain 9.4 g of the product, ee>99%, dr>99:1. .

Embodiment 2

[0032] Add 100 g of 100 mM phosphate buffer solution (pH=7.5) into a 250 mL reaction flask, add 10 g of p-nitrobenzaldehyde, 10 g of L-threonine and 12 g of glucose under stirring, and stir the system for 10 minutes. Use 3M sodium hydroxide to adjust the pH of the system to 7.5, control the temperature of the system to 35°C and stir evenly, then add 20 mg of pyridoxal phosphate, 20 mg of nicotinamide adenine dinucleotide, and 0.5 g of transaldolase enzyme powder (purchased from Suzhou Yinhang Biotechnology Co., Ltd., product number is YH1062), 0.5g acetaldehyde reductase enzyme powder (purchased from Suzhou Pivot Biotechnology Co., Ltd., product number is YH2012) and 0.5g glucose dehydrogenase enzyme powder (purchased from Suzhou Pivot Biotechnology Co., Ltd. (the product number is YH1901), started the stirring reaction, and kept the pH of the system at 7.5 with 3M NaOH during the reaction. After 20 hours, a sample was taken for HPLC detection, and the conversion rate was above...

Embodiment 3

[0034] Add 100 g of 100 mM phosphate buffer (pH=7.5) into a 250 mL reaction flask, add 10 g of p-nitrobenzaldehyde, 10 g of L-threonine and 10 g of isopropanol under stirring, and stir the system for 10 minutes. Use 3M sodium hydroxide to adjust the pH of the system to 7.5, control the temperature of the system to 35°C and stir evenly, then add 20 mg of pyridoxal phosphate, 20 mg of nicotinamide adenine dinucleotide, and 0.5 g of transaldolase enzyme powder (purchased from Suzhou Yinhang Biotechnology Co., Ltd., product number is YH1062), 0.5g acetaldehyde reductase enzyme powder (purchased from Suzhou Pivot Biotechnology Co., Ltd., product number is YH2012) and 0.5g alcohol dehydrogenase enzyme powder (purchased from Suzhou Pivot Biotechnology Co., Ltd., product number is YH2023), start stirring reaction, after 20 hours sampling HPLC detection, the conversion rate is more than 99%. After the reaction was completed, the white solid was collected by filtration, and the white so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com