Cyanide-free silver plating electroplating solution and preparation method

A cyanide-free silver plating and electroplating solution technology, applied in the field of electroplating technology, can solve the problems of wear resistance, poor corrosion resistance, rough coating, poor conductivity, etc., achieve good corrosion resistance, reduce pinholes in the coating, and good conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

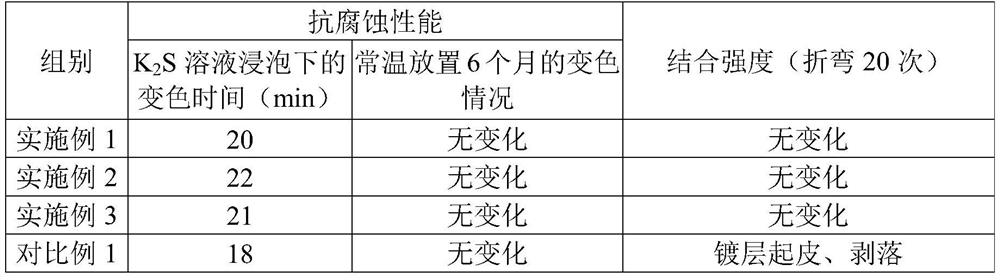

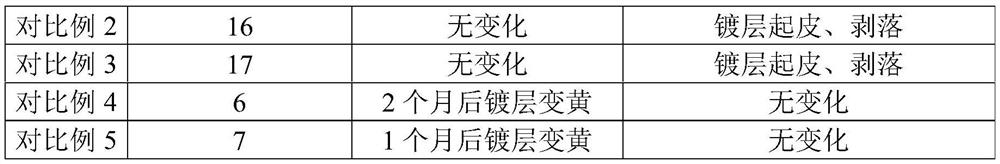

Examples

Embodiment 1

[0030] Among them, the reagents used in the present invention are commonly used reagents, which can be purchased from conventional reagent production and sales companies. Embodiment 1 A kind of copper plated piece that adopts cyanide-free silver-plating electroplating solution electroplating

[0031] Described cyanide-free silver plating electroplating solution, is made up of the component of following mass concentration:

[0032] Silver nitrate 30g / L, complexing agent 50g / L, sodium citrate 20g / L, potassium carbonate 5g / L, sodium lauryl sulfate 16g / L, disodium hydrogen phosphate 5g / L, brightener 5g / L, Ammonia water 15g / L.

[0033] The complexing agent is composed of aminoacetic acid, tryptophan and 2,2-bipyridine in a weight ratio of 5:4:3.

[0034] The brightener is composed of niacin and urea in a weight ratio of 8:3.

[0035] The preparation method of described cyanide-free silver plating electroplating solution, comprises the steps:

[0036] S1. Dissolve complexing age...

Embodiment 2

[0041] Clean the surface of the copper part, immerse it in the cyanide-free silver plating solution, use the copper plated part as the cathode, and the silver plate as the anode. After the silver plating is completed, take out the plated part from the electroplating solution, and clean the surface with distilled water. Cool air dry. The temperature during the electroplating is 20°C, and the current density is 0.5A / dm 2 , Plating time is 10min. Embodiment 2 A kind of copper plated piece that adopts cyanide-free silver-plating electroplating solution electroplating

[0042] Described cyanide-free silver plating electroplating solution, is made up of the component of following mass concentration:

[0043] Silver nitrate 35g / L, complexing agent 70g / L, sodium citrate 30g / L, potassium carbonate 14g / L, sodium lauryl sulfate 20g / L, disodium hydrogen phosphate 12g / L, brightener 20g / L, Potassium hydroxide 20g / L.

[0044] The complexing agent is composed of glycine, tryptophan and 2,...

Embodiment 3

[0052] Clean the surface of the copper part, immerse it in the cyanide-free silver plating solution, use the copper plated part as the cathode, and the silver plate as the anode. After the silver plating is completed, take out the plated part from the electroplating solution, and clean the surface with distilled water. Cool air dry. The temperature during the electroplating is 23°C, and the current density is 2.0A / dm 2 , Plating time is 10min. Embodiment 3 A kind of copper plated piece that adopts cyanide-free silver-plating electroplating solution electroplating

[0053] Described cyanide-free silver plating electroplating solution, is made up of the component of following mass concentration:

[0054] Silver nitrate 40g / L, complexing agent 100g / L, sodium citrate 40g / L, potassium carbonate 20g / L, sodium lauryl sulfate 25g / L, disodium hydrogen phosphate 18g / L, brightener 30g / L, Sodium hydroxide 25g / L.

[0055] The complexing agent is composed of aminoacetic acid, tryptophan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com