Dielectric electrolyte, lithium ion battery and preparation method of lithium ion battery

An electrolyte and dielectric technology, which is applied in the field of dielectric electrolyte preparation, can solve the problems of insignificant improvement of charge and discharge efficiency, growth of lithium dendrites, easy combustion of electrolyte, and achieves unaffected cycle and rate performance and high room temperature conductivity. And the effect of good temperature resistance and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

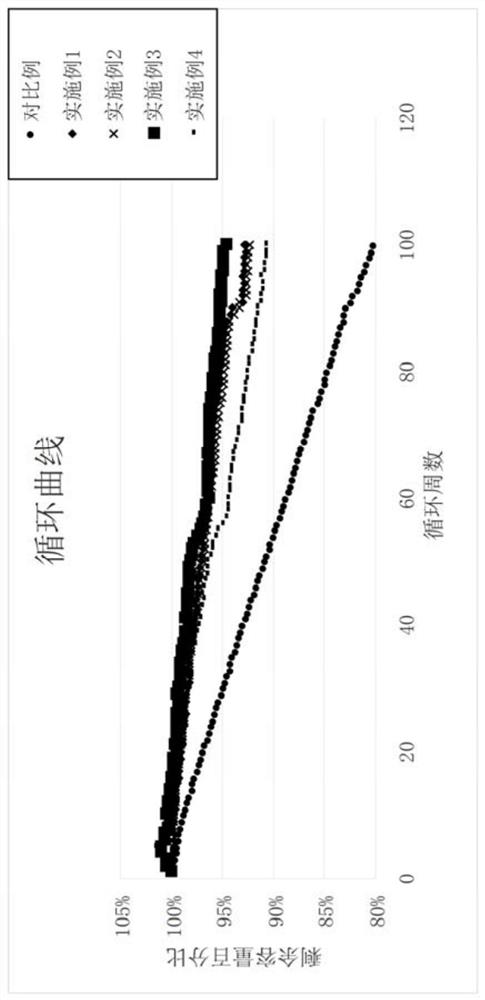

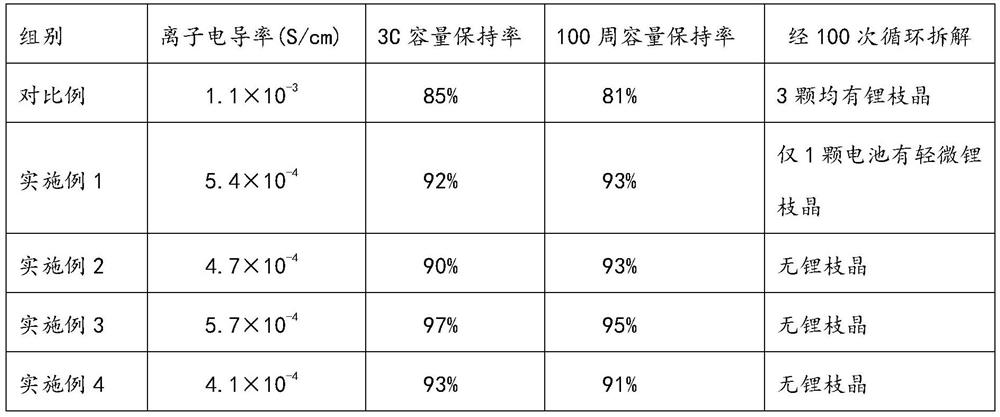

[0039] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples. In this embodiment, the high-nickel material 811 is used for the positive electrode, which can be replaced by other materials. Different material systems have different energy densities, but this does not affect the experimental rules. Lithium metal is used for the negative electrode.

[0040] The electrolyte formula adopts the conventional formula: the solvent component of the electrolyte is 0.2 mol / L of fluorinated diether, EC: EMC = 1:1, the amount of additive is 0.1-0.3 mol / L; the lithium salt is LiPF 6 , the addition amount is 1-1.5mol / L; the choice of electrolyte only affects the conductivity of the liquid system, and has no effect on the performance of the medium electrolyte;

[0041] The quasi-solid electrolyte uses methyl methacrylate-LAGP-ZMS-5, and the specific preparation method is as follows:

[004...

Embodiment 2

[0053] The main difference between this embodiment and embodiment 1 is:

[0054] Polyethylene oxide is selected as the polymer electrolyte matrix; ethylene carbonate is selected as the plasticizer; the raw material ratio of the dielectric electrolyte is: polyethylene oxide 80%, LAGP 15%, propylene carbonate 5%; 4 times.

Embodiment 3

[0056] The main difference between this embodiment and embodiment 1 is:

[0057] Polymethyl methacrylate is selected as the polymer electrolyte matrix; ethyl methyl carbonate is selected as the plasticizer; the raw material ratio of the dielectric electrolyte: 90% polymethyl methacrylate, 6% LAGP, 4% propylene carbonate; the thickness of the dielectric electrolyte layer is 4um , Acetonitrile consumption is 4 times of raw material quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com