Method and device for preparing nickel matte

A technology of nickel matte and spray drying method, which is applied in the field of preparation of nickel matte, can solve the problem of no harmless disposal of sulfur slag, and achieve the effects of low valuable metal content, good fluidity, and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

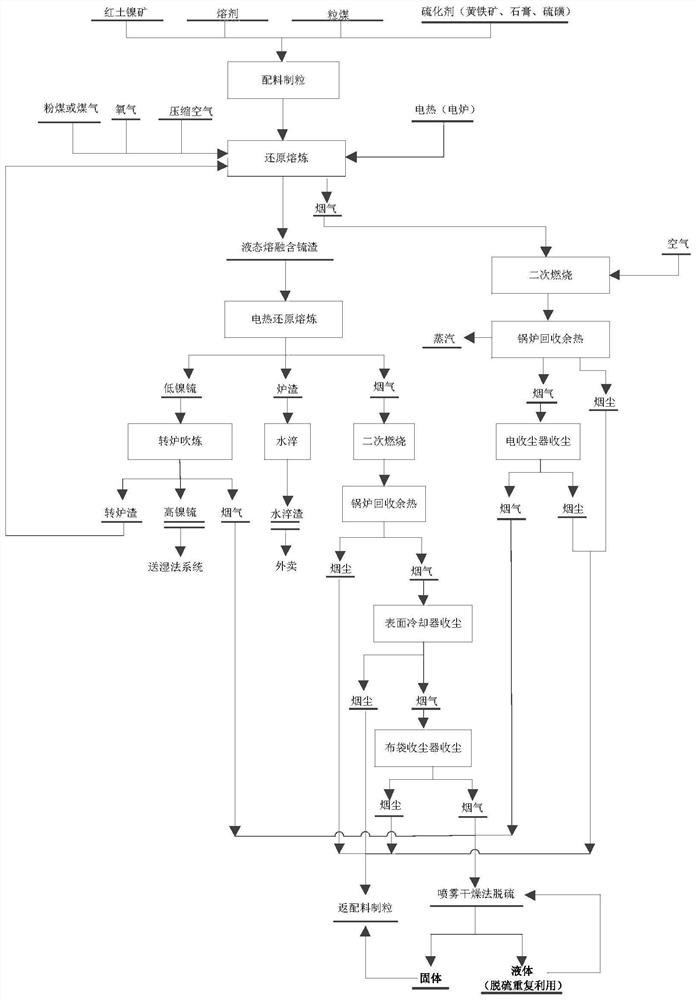

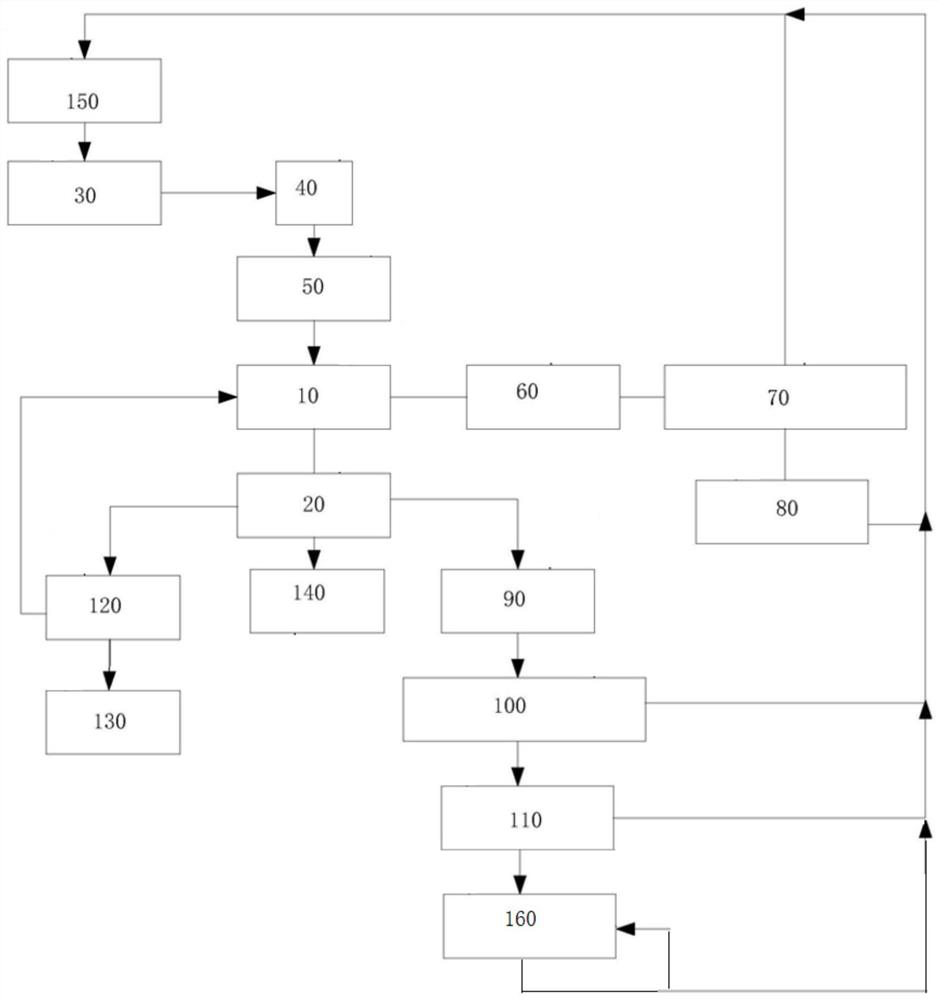

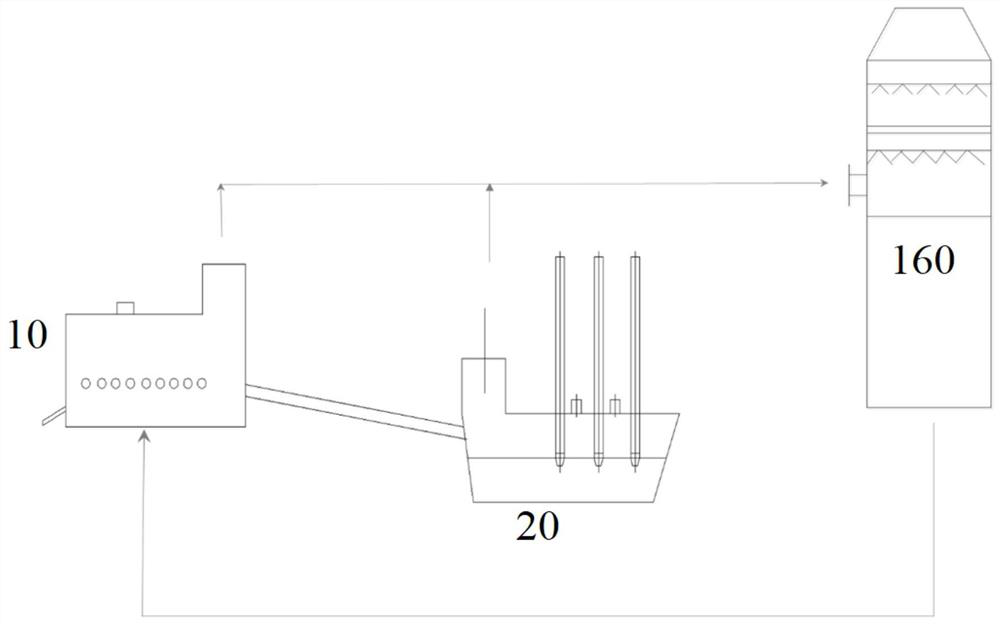

[0060] refer to figure 1

[0061] Top blowing pre-reduction stage

[0062] After the laterite nickel ore is dried in the sun, part of the free water is volatilized, and it is appropriate to loosen it moderately. Laterite nickel ore, reduced coal, vulcanizing agent (pyrite), and slagging flux (including desulfurization solid products) with suitable water content (water content 16-25%) are granulated by the disc granulator, and then sent by the belt conveyor The silo in front of the melting furnace is continuously fed into the melting furnace through a quantitative feeder and a mobile belt conveyor.

[0063] Oxygen-enriched air (~60%) and reducing gas are blown into the molten pool through the pulverized coal spray gun on the top of the furnace body, and the injection pressure of reducing gas and oxygen-enriched air is 0.2-0.8MPa. The combustion flame of the spray gun directly contacts the melt, and the combustion flue gas stirs the molten pool, which strengthens the mass tra...

Embodiment 2

[0073] Submerged electric furnace pre-reduction stage

[0074] After the laterite nickel ore is dried in the sun, part of the free water is volatilized, and it is appropriate to loosen it moderately. After the laterite nickel ore, reduced coal, vulcanizing agent (sulfur) and slagging flux (including desulfurization solid products) with suitable water content are granulated by the disc granulator, they are sent to the feeding bin of the electric furnace by the belt conveyor, and then passed through the quantitative feeder, The mobile belt conveyor continuously feeds into the electric furnace.

[0075] After adding the charge, start to melt with electricity. After the molten pool is formed, the stirring of the molten pool by the electric furnace itself strengthens the mass transfer of the molten pool, accelerates the reaction, and makes the lateritic nickel ore granular materials melt rapidly; lime and other fluxes are added from the feeding hole. Adjust the slag type and melti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com