Preparation method of composite-metal-coated foam metal material

A technology of metal foam and composite metal, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of material failure and other problems, and achieve the effect of controllable metal content, simple overall process and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

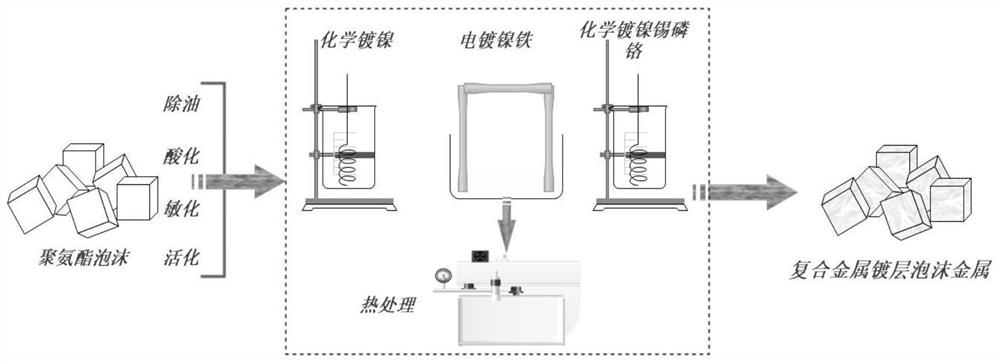

[0035] Such as figure 1 Shown, a kind of preparation method of composite metal coating foam metal material may further comprise the steps:

[0036] (1) Degreasing, acidifying, sensitizing and activating the polyurethane foam (15cm×10cm×1cm) to obtain the modified polyurethane foam; wherein, the degreasing treatment is to remove the polyurethane foam with a potassium hydroxide solution with a concentration of 50g / L The oil pollution, the degreasing time is 20min, and the temperature is 70°C. Acidification treatment is to treat the polyurethane foam after degreasing in 1g / L oxalic acid solution for 20min, and then wash it to neutral with deionized water to obtain the polyurethane foam after pickling; sensitization treatment is to treat the polyurethane foam after pickling Treat it in a mixed solution of stannous chloride 5g / L and hydrochloric acid 5ml / L for 15 minutes, and then wash it with deionized water until neutral to obtain a sensitized polyurethane foam; The final polyure...

Embodiment 2

[0044] A method for preparing a composite metal-coated metal foam material, comprising the following steps:

[0045] (1) Degreasing, acidifying, sensitizing and activating the polyurethane foam (15cm×10cm×1cm) to obtain the modified polyurethane foam; wherein, the degreasing treatment is to remove the polyurethane foam with a potassium hydroxide solution with a concentration of 100g / L The oil pollution, the degreasing time is 10min, and the temperature is 70°C. Acidification treatment is to treat the polyurethane foam after degreasing in 3g / L oxalic acid solution for 20min, and then wash it to neutral with deionized water to obtain the polyurethane foam after pickling; sensitization treatment is to treat the polyurethane foam after pickling Treat it in a mixed solution of stannous chloride 8g / L and hydrochloric acid 10ml / L for 10 minutes, then wash it with deionized water until neutral to obtain a sensitized polyurethane foam; The final polyurethane foam was processed in 100m...

Embodiment 3

[0053] A method for preparing a composite metal-coated metal foam material, comprising the following steps:

[0054] (1) Degreasing, acidifying, sensitizing and activating the polyurethane foam (15cm×10cm×1cm) to obtain the modified polyurethane foam; wherein, the degreasing treatment is to remove the polyurethane foam with a potassium hydroxide solution with a concentration of 120g / L The oil stain, the degreasing time is 5min, and the temperature is 75°C. Acidification treatment is to treat the polyurethane foam after degreasing in 5g / L oxalic acid solution for 10min, and then wash it to neutral with deionized water to obtain the polyurethane foam after pickling; sensitization treatment is to treat the polyurethane foam after pickling Treat it in a mixed solution of stannous chloride 10g / L and hydrochloric acid 10ml / L for 10 minutes, then wash it with deionized water until neutral to obtain a sensitized polyurethane foam; The final polyurethane foam was processed in 200mg / mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com