Red rice cake production process

A production process and technology of red rice, applied in food science and other directions, can solve the problems that affect the sensory quality of red rice cake, the powder of bride cake is hard and difficult to digest, etc., and achieves the effect of soft and tender taste, fine powder and good absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

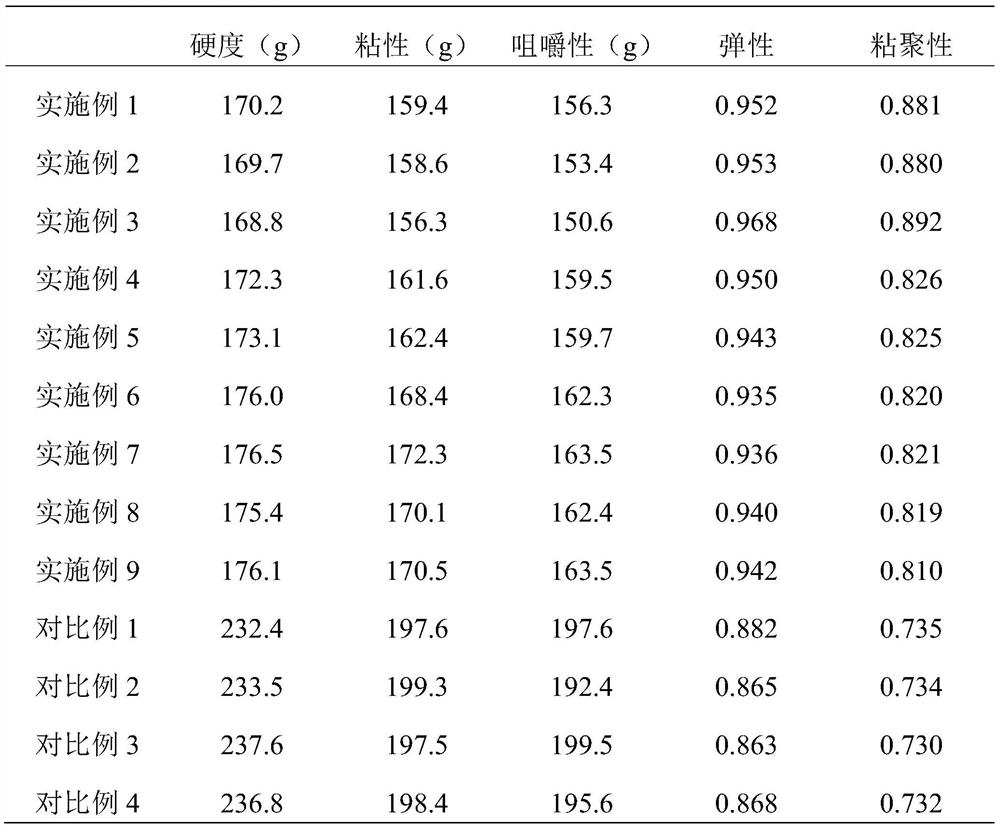

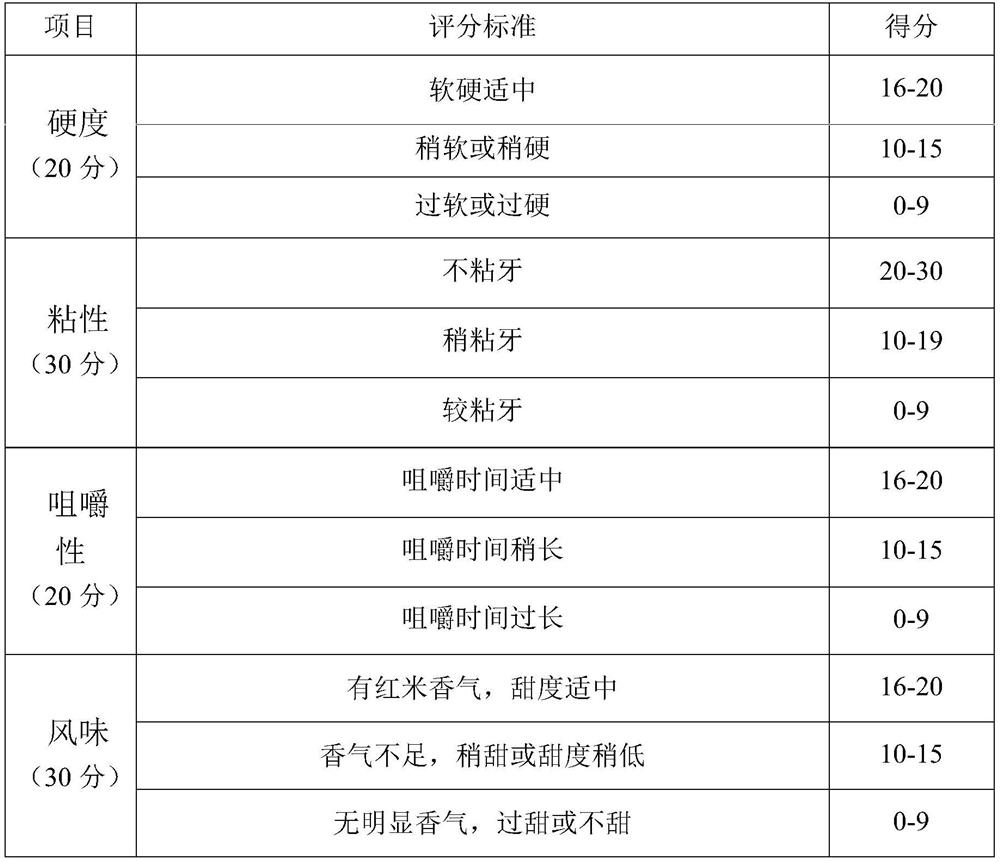

Examples

Embodiment 1

[0028] A kind of preparation technology of red rice cake, comprises the following steps:

[0029] S1, the red rice cake includes the following raw materials in parts by weight: 50 parts of red rice flour, 2 parts of white sugar;

[0030] S2. Enzymatic hydrolysis of red rice: After pretreatment of raw red rice, heat up to 30°C, add glucosidase with 0.12% weight of red rice while stirring for the first heat preservation enzymolysis for 2.5h, then heat up to 55°C, add The enzymolysis solution of 0.4% of the weight of red rice was subjected to the second heat preservation enzymolysis for 4h; As, the enzyme activity of the α-amylase is 10000u / g, the enzyme activity of Monascus esterase is 2000u / g, and the enzyme activity of catalase is 50000u / g;

[0031] S3. Preparation of red rice flour: after enzymatically deactivating the red rice at 100°C and milling, remove the rice skin, add 0.3 times its weight of water to the obtained brown rice, stir and infiltrate for 60 minutes, and the...

Embodiment 2

[0034] A kind of preparation technology of red rice cake, comprises the following steps:

[0035] S1, the red rice cake includes the following raw materials in parts by weight: 80 parts of red rice flour, 8 parts of white sugar;

[0036] S2. Enzymolysis of red rice: After pretreatment of raw red rice, heat up to 50°C, add glucosidase with 2% weight of red rice while stirring for the first heat preservation enzymolysis for 4 hours, then heat up to 75°C, add red rice The enzymolysis solution with 2.6% rice weight was subjected to the second heat preservation enzymolysis for 8 hours; the enzymolysis solution was mixed by α-amylase, monascus esterase and catalase in a mass ratio of 1:3:0.5 , the enzyme activity of the α-amylase is 20000u / g, the enzyme activity of monascus esterase is 3000u / g, and the enzyme activity of catalase is 80000u / g;

[0037] S3. Preparation of red rice flour: the enzymatically hydrolyzed red rice is inactivated at 120° C. and milled, then the skin of the ...

Embodiment 3

[0040] A kind of preparation technology of red rice cake, comprises the following steps:

[0041] S1, the red rice cake includes the following raw materials in parts by weight: 70 parts of red rice flour, 5 parts of white sugar;

[0042] S2. Enzymatic hydrolysis of red rice: after pretreatment of raw red rice, heat up to 40°C, add glucosidase of 0.16% by weight of red rice while stirring for the first heat preservation enzymolysis for 3.2h, then heat up to 60°C, add The enzymolysis solution with 1.5% weight of red rice was subjected to the second heat preservation enzymolysis for 6 hours; As, the enzyme activity of the α-amylase is 150000u / g, the enzyme activity of Monascus esterase is 2500u / g, and the enzyme activity of catalase is 70000u / g;

[0043] S3. Preparation of red rice flour: after enzymatically deactivating the red rice at 110°C and grinding it, removing the rice skin, adding 0.9 times its weight of water to the obtained brown rice, stirring and infiltrating for 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap