Metal-doped titanium dioxide photocatalytic degradation material for treating printing and dyeing wastewater and preparation method of metal-doped titanium dioxide photocatalytic degradation material

A metal-doped, titanium dioxide technology, applied in the field of photocatalytic degradation of colored pollution, can solve the problems of the need to improve the photodegradation rate and efficiency, the poor photodegradation effect of dye wastewater, and the limited photocatalytic ability, and achieve excellent photocatalytic ability, Improve photocatalytic ability, improve the effect of photocatalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

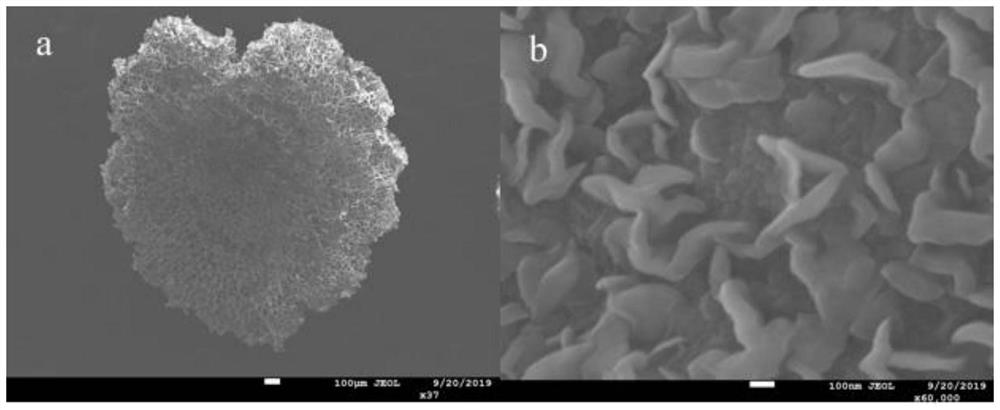

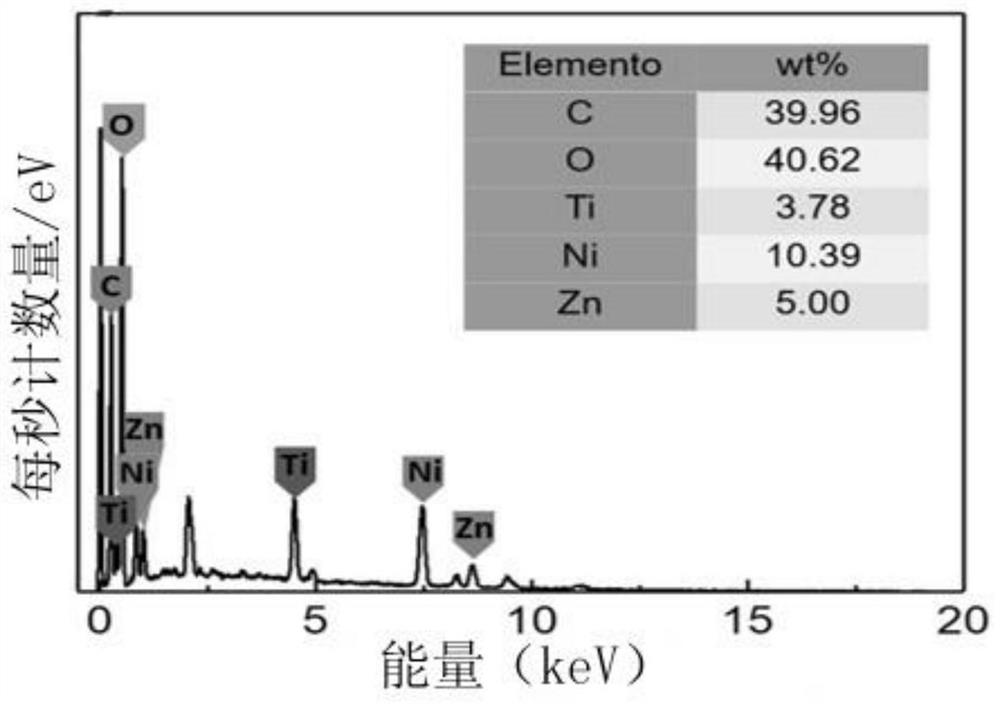

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a metal-doped titanium dioxide photocatalytic degradation material for treating printing and dyeing wastewater, comprising the following steps:

[0032] S1. Mix the alcoholic organic solvent and water uniformly according to a predetermined volume ratio to obtain a mixed solution; then place the surfactant in the mixed solution and stir to obtain a washing solution;

[0033] S2, placing the rush fiber in the washing solution obtained in step S1, and drying after washing to obtain the washed rush fiber;

[0034] S3. Mix nickel nitrate, zinc nitrate and urea according to a predetermined molar ratio and dissolve them in water to obtain solution A; disperse butyl titanate in ethanol to obtain solution B;

[0035]S4. Slowly add the solution A obtained in step S3 into the solution B, stir rapidly to obtain a mixed dispersion system; place the washed rush fiber obtained in step S2 in the mixed dispersion system, and After fully rea...

Embodiment 1

[0047] This embodiment provides a method for preparing a metal-doped titanium dioxide photocatalytic degradation material for treating printing and dyeing wastewater, including the following steps:

[0048] S1, with ethanol as alcoholic organic solvent, ethanol and water are mixed uniformly by volume ratio 30%:70%, obtain mixed solution; Then use monolauryl phosphate as surfactant, place monolauryl phosphate in the In the mixed solution, the washing liquid is obtained after stirring evenly, and the concentration of monolauryl phosphate in the washing liquid is 0.3g / L;

[0049] S2, placing the rush fiber in the washing solution obtained in step S1 at a water bath ratio of 1:50, washing at 30°C for 30 minutes, and drying at 60°C for 40 minutes to obtain the washed rush fiber;

[0050] S3, take by weighing 1.746g nickel nitrate hexahydrate, 0.891g zinc nitrate hexahydrate and 1.08g urea, make the mol ratio of nickel nitrate, zinc nitrate and urea be 2:1:6, then mix it and dissolv...

Embodiment 2~11

[0060] Embodiments 2 to 11 provide a method for preparing a metal-doped titanium dioxide photocatalytic degradation material for treating printing and dyeing wastewater. Compared with Example 1, the difference is that nickel nitrate, zinc nitrate and urea in step S3 are changed. The molar ratio of butyl titanate, the mass fraction of butyl titanate or the molar ratio of titanate, nickel nitrate and zinc nitrate in the mixed dispersion system in step S4, the mass ratio of rush fiber to the mixed dispersion system, the rest of the steps are unchanged, and will not be described here. Let me repeat. The relevant parameter values in steps S3 and S4 of each embodiment are shown in Table 1.

[0061] Table 1 embodiment 2~11 in the relevant parameter value in step S3 and S4

[0062]

[0063]

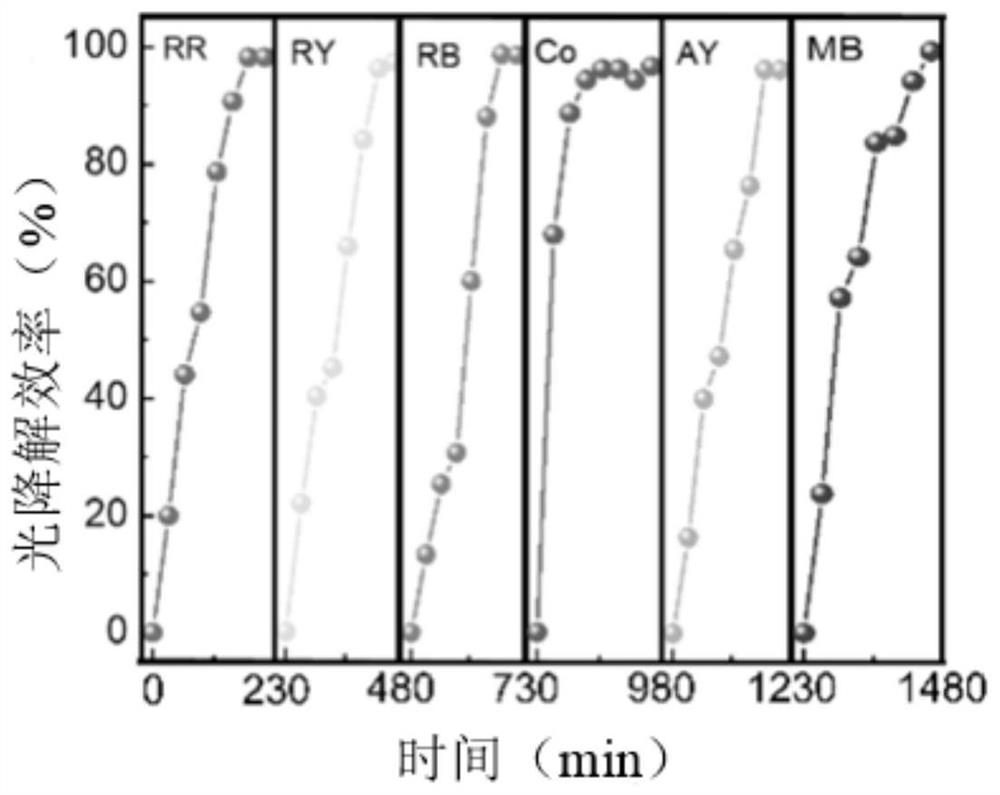

[0064] Taking the dye reactive red as an example, the photocatalytic degradation time and photocatalytic degradation efficiency of the metal-doped titanium dioxide photocatalytic degrada...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com