Energy-saving method for improving combustion process

A process and combustion pipeline technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of high chemical reaction temperature, low effective energy, slow reaction, etc., and achieve low chemical reaction temperature, accelerated reaction speed, atomization React discrete effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] "Composite polarization technology" is a high-tech technology integrating "nano-catalysis technology", "magnetic polarization technology" and "shielding technology". Under the premise of satisfying the "law of energy conversion and conservation", the process optimization technology proposed for the traditional combustion reaction process reaction process, that is, before the primary reaction of the fuel medium, it is superimposed by the "catalysis of nanomaterials" and "super-stacked polarization force". The formed ultra-high coercive force is excited to do work, and the fuel molecules instantly form a super-large paramagnetic molecule, which constitutes an extremely active T-state excited molecule. Because the super-large paramagnetic molecule carries huge and highly energy-rich molecules to participate in all levels of reactions , so that all reaction processes are less affected by temperature, and then the atomization reaction is more discrete, the gasification reacti...

Embodiment 2

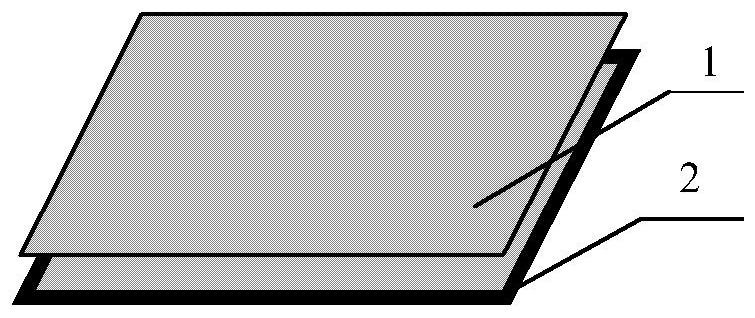

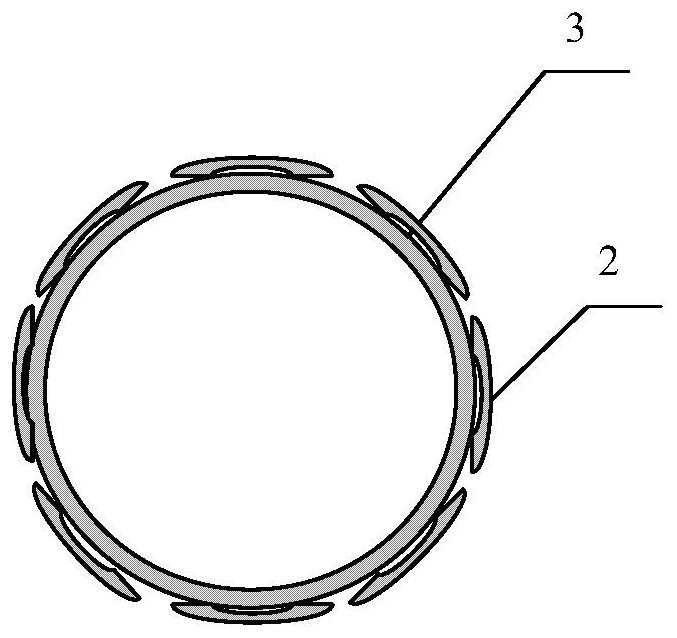

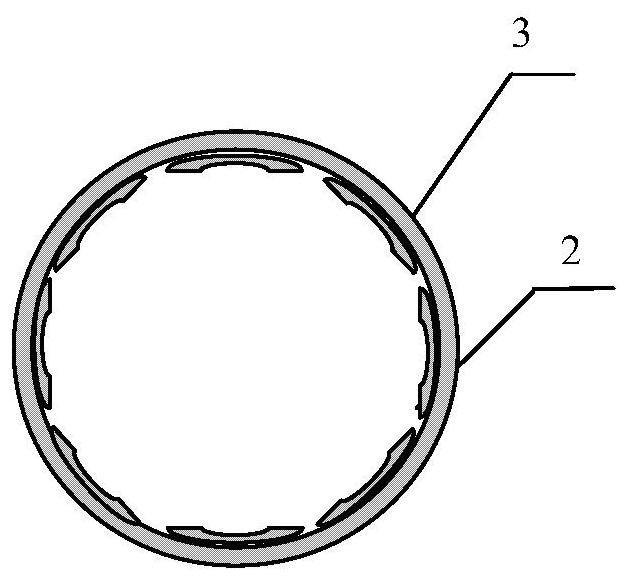

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an energy-saving method for improving the combustion process: at least one piece of composite magnetic graphene 1 corresponding to the same pole and the same direction is fixed on the soft board 2 in a horizontal tiled or vertically superimposed manner, and the magnetic graphene 1 is fixed The flexible board 2 is connected on the inner wall or outer wall of the combustion pipeline 3, and at least one composite magnetic graphene 1 is horizontally tiled to form a super-strong superimposed polar magnetic field, and the longitudinal superposition of at least one composite magnetic graphene 1 forms a super-strong magnetic field. The polar magnetic field is superimposed, and the circumferential surface of the combustion pipe 3 forms a ring-shaped homopolar structure. The superimposed superimposed polar magnetic field makes the electrons in the molecules or atoms of the combustion medium parallel to the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com