Fe-N-C catalyst, method of preparation and uses thereof

A technology of application and catalytic material, applied in the field of catalysts for CO2 electroreduction, can solve the problems of low partial current density and low CO generation rate, and achieve the effect of reducing production costs and avoiding regeneration requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

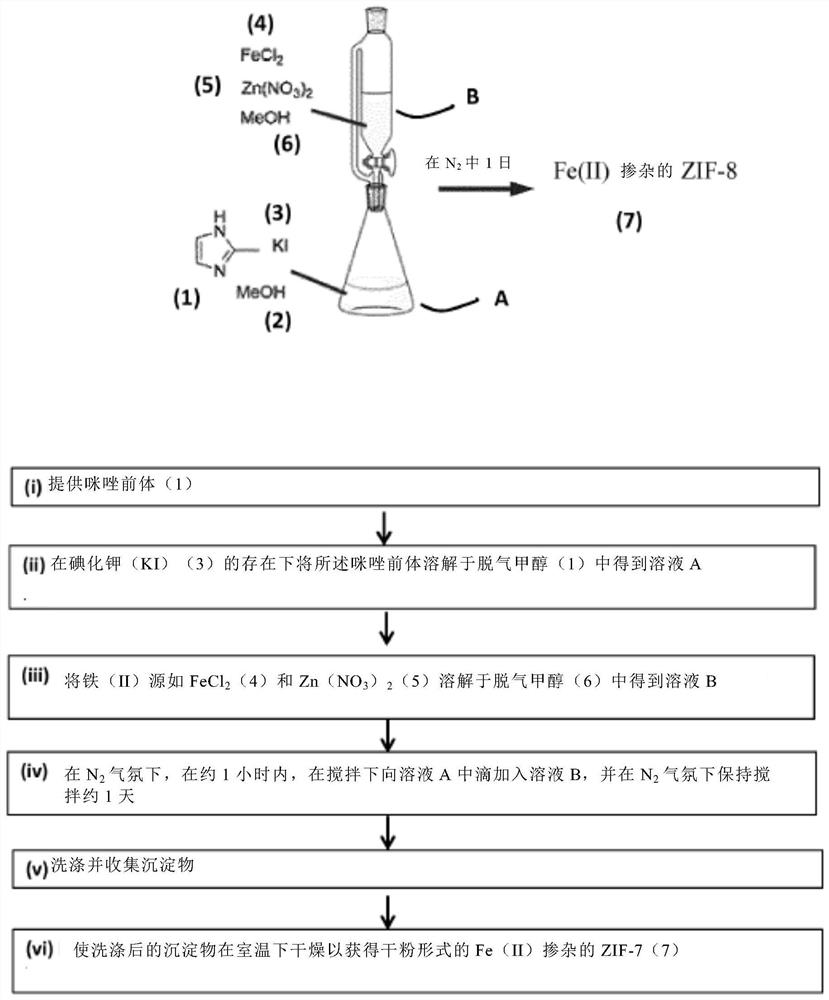

[0107] Embodiment 1: the preparation of the Zn-ZIF precursor of Fe (II) doping

[0108] The inventive method for preparing Fe(II)-doped Zn-zeolite imidazole frameworks (ZIFs) according to the invention is as Figure 1B shown for Fe(II)-doped zinc imidazole (ZIF-8). In order to prevent the oxidation of Fe(II) species during the reaction, before use by bubbling N 2 The reaction medium, i.e. methanol (MeOH) or ethanol, was degassed, and the Fe(II)-doped Zn-ZIF-8 material was synthesized in a glove box as follows:

[0109] The imidazolate precursor is provided to prepare Solution A:

[0110] First, 1.314 g of 2-methylimidazole (2-mIm) was provided as an imidazolate precursor, and 0.076 g of potassium iodide (KI) was dissolved in 15 mL of MeOH to form solution A.

[0111] Iron(II) chloride is supplied to prepare solution B:

[0112] 0.080 g FeCl 2 4H 2 O or 0.063 g FeCl 2 As Fe(II) precursor and 1.190 g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 25 mL of MeOH to form solution B...

Embodiment 2

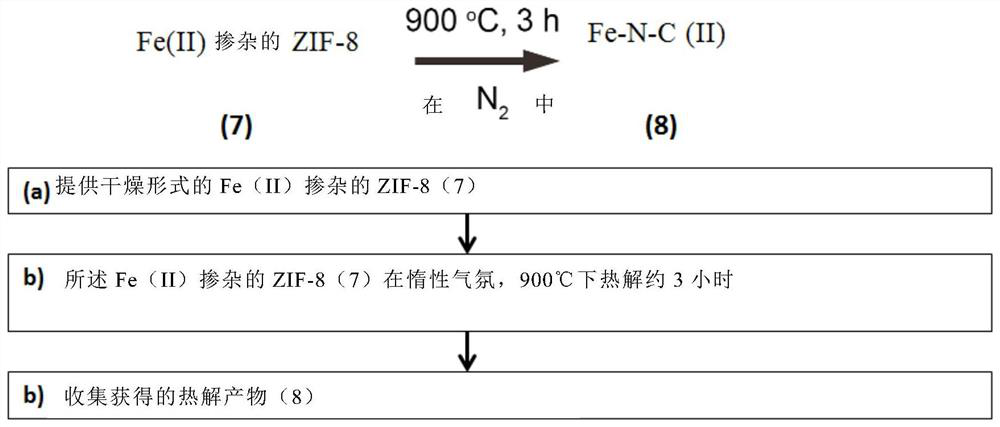

[0117] Embodiment 2: prepare catalytic material of the present invention by Fe (II) doped Zn-ZIF

[0118] exist Figure 1A The inventive process for the preparation of catalysts comprising Fe single atoms on N-doped carbon substrates obtained from Fe(II)-doped Zn-ZIFs according to the invention is described in , using the Fe obtained in Example 1 (II) Doped zinc imidazolium (ZIF-8) as a precursor for pyrolysis. During the transfer from the glove box to the tube furnace, the Fe(II)-doped zinc imidazolium (ZIF-8) precursor obtained in Example 1 was immersed in hexane to prevent possible exposure to air. oxidation. Then in a tube furnace at 900 °C at 100 mL min -1 N 2 Pyrolysis was carried out for 3 hours at the flow rate, and the heating rate was 5°C·min -1 . Catalytic material obtained by pyrolysis as black powder. The obtained yield was about 90% based on Fe.

Embodiment 3

[0119] Example 3: Characterization of Fe(II)-doped zinc imidazole (ZIF-8) precursor and its pyrolysis products

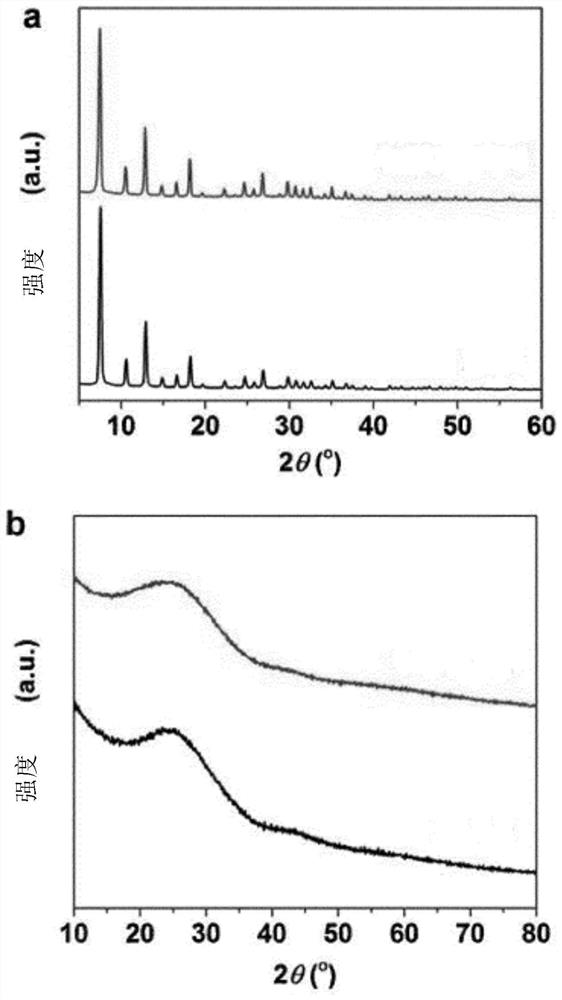

[0120] Such as figure 2 As reported on a, compared with the same method as in Example 1 in the absence of FeCl 2 or FeCl 2 4H 2 X-ray diffraction (XRD) patterns of undoped ZIF-8 and the Fe(II)-doped zinc imidazolium (ZIF-8) precursor of the present invention prepared in the presence of O. Such as figure 2 b, comparing the XRD patterns of the material obtained after pyrolysis of undoped ZIF-8 and Fe(II)-doped ZIF-8.

[0121] To prepare samples for XRD characterization, the material in solid form was first dispersed in a small amount of ethanol, dropped on a glass slide, and then dried naturally. XRD measurements on an XPert with monochromatic Cu Kα radiation and a fast Si-PIN multiband detector TM performed on a Philips diffractometer.

[0122] Such as figure 2 As shown in a, undoped ZIF-8 (top) and Fe(II)-doped ZIF-8 (bottom) have similar X-ray diffraction (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com