Phospholipid-like amphiphilic block copolymer-based ultrasonic contrast agent and preparation method thereof

A technology of amphiphilic block and ultrasound contrast agent, which can be applied in echo/ultrasonic imaging agent, analysis of solids with sound wave/ultrasonic wave/infrasonic wave, material analysis with sound wave/ultrasonic wave/infrasonic wave, etc. It can solve problems such as shell rupture, To achieve the effect of long duration, enhanced image effect and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. The preparation of phospholipid-like amphiphilic block copolymer-based ultrasound contrast agent, the specific steps are as follows:

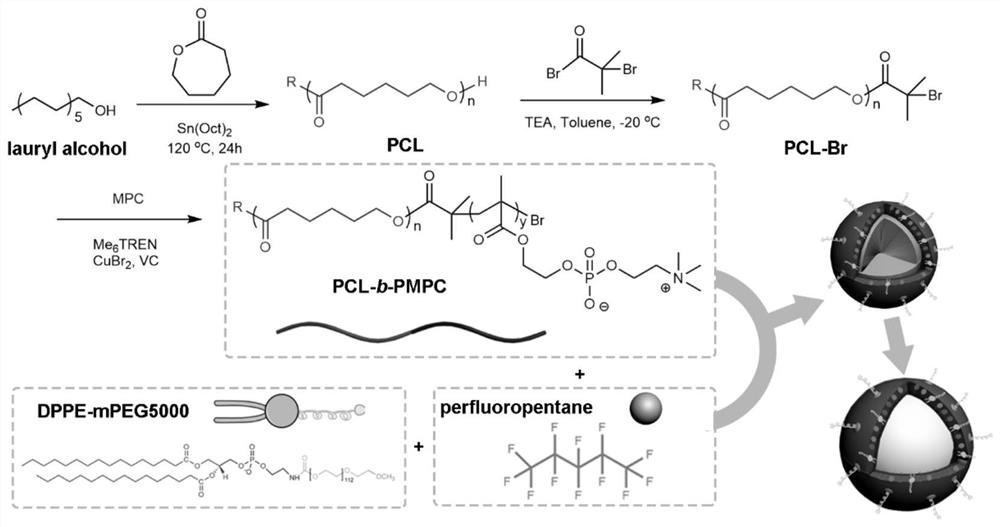

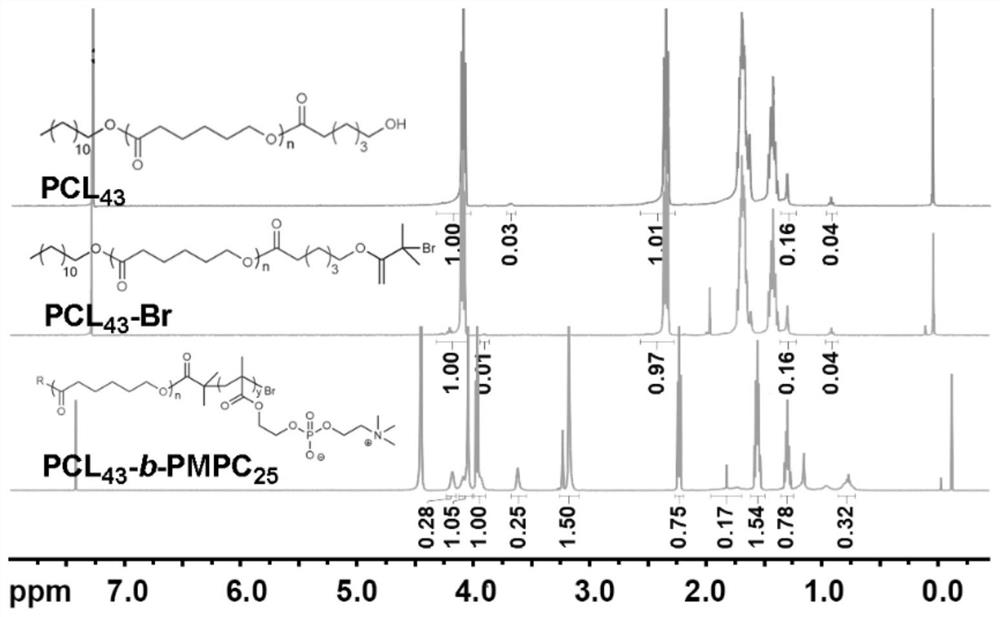

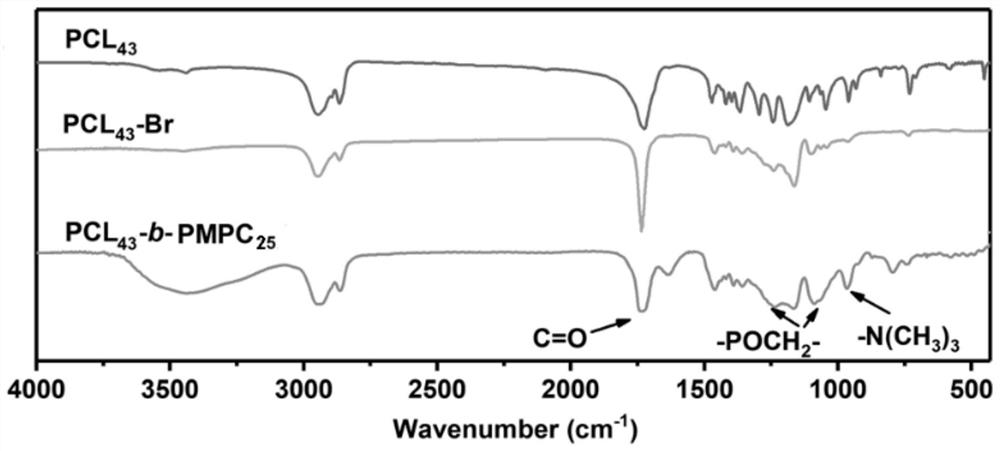

[0056] 1) Preparation of amphiphilic block copolymer polymer PCL 43 -b-PMPC 25 :

[0057] ①Preparation of PCL first: lauryl alcohol (0.82g, 0.004mol), ε-CL (10.13g, 0.089mol) and Sn(Otc) 2 (4.05 g, 0.01 mol) was added to the reaction vessel. remove the O 2 and residual water. The reaction was carried out under vacuum at 120°C for 24 hours. Dissolve the crude product in CH 2 Cl 2 , and purified by cold methanol precipitation to obtain PCL.

[0058] ②Prepare PCL-Br next: Dissolve the PCL-OH (7.00g, 0.002mol) and triethylamine (0.96mL, 0.007mmol) obtained in ① in tetrahydrofuran (THF); 2 In an atmosphere of 2-bromoisobutyryl bromide (0.85mL, 0.0069mmol) was added dropwise to the above solution at -20°C; the reaction was carried out at room temperature for 48-72 hours, and passed through a column of neutral alumina to remove Qua...

Embodiment 2

[0074] The PCL-b-PMPC contrast agent was prepared by a shearing method different from that in Example 1.

[0075] The specific preparation process of PCL-b-PMPC phospholipid block polymer nano-ultrasound contrast agent prepared by shearing method is as follows:

[0076] Weigh 3 mg of PCL-b-PMPC copolymer and 1 mg of DPPE-mPEG 5000 and dissolve them in 567 μL of tetrahydrofuran (THF) and 283 μL of methanol (MeOH) (2:1, v / v). PBS buffer (0.01M, pH=7.4), and then 150 μL of perfluoropentane (PFP) was added. Under the condition of ice-water bath, add liquid perfluoropentane, adopt the electric internal cutting homogenization method, the homogenization speed is 12000-30000rpm, and the homogenization time is 1-3min. After homogenization, a milky white product wrapped with perfluoropentane Block polymer mixture.

[0077] The above mixed solution is phase-transformed with a therapeutic ultrasound instrument to form a PCL-b-PMPC phospholipid amphiphilic block copolymer-based ultrasoun...

Embodiment 3

[0078] Embodiment 3 freeze-drying method prepares PCL-b-PMPC contrast agent

[0079] The specific preparation process of the PCL-b-PMPC phospholipid amphiphilic block copolymer base ultrasound contrast agent prepared by freeze-drying method is as follows:

[0080] Weigh 3 mg of PCL-b-PMPC copolymer and 1 mg of DPPE-mPEG 5000 and dissolve them in 567 μL of tetrahydrofuran (THF) and 283 μL of methanol (MeOH) (2:1, v / v). PBS buffer (0.01M, pH=7.4), and then 150 μL of perfluoropentane (PFP) was added. Under the condition of ice-salt water bath, conduct ultrasonic vibration, probe frequency 24KHz, power 35W, ultrasonic on 3s, off 6s, act for 3min, form a milky white suspension, then centrifuge under 3000g centrifugal force for 5min, discard the supernatant, each Add 6 mL of 10 wt% sucrose solution for resuspension. 10mL vials were used, divided into 2mL volumes per bottle, pre-frozen in a -20°C refrigerator overnight, and freeze-dried in a freeze dryer for 24 hours, in which the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com