High-throughput electrochemical synthesis and testing all-in-one machine and using method thereof

An electrochemical and high-throughput technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of cumbersome refueling, single experimental results, and low work efficiency, so as to improve the screening quality, speed up the screening process, and facilitate use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

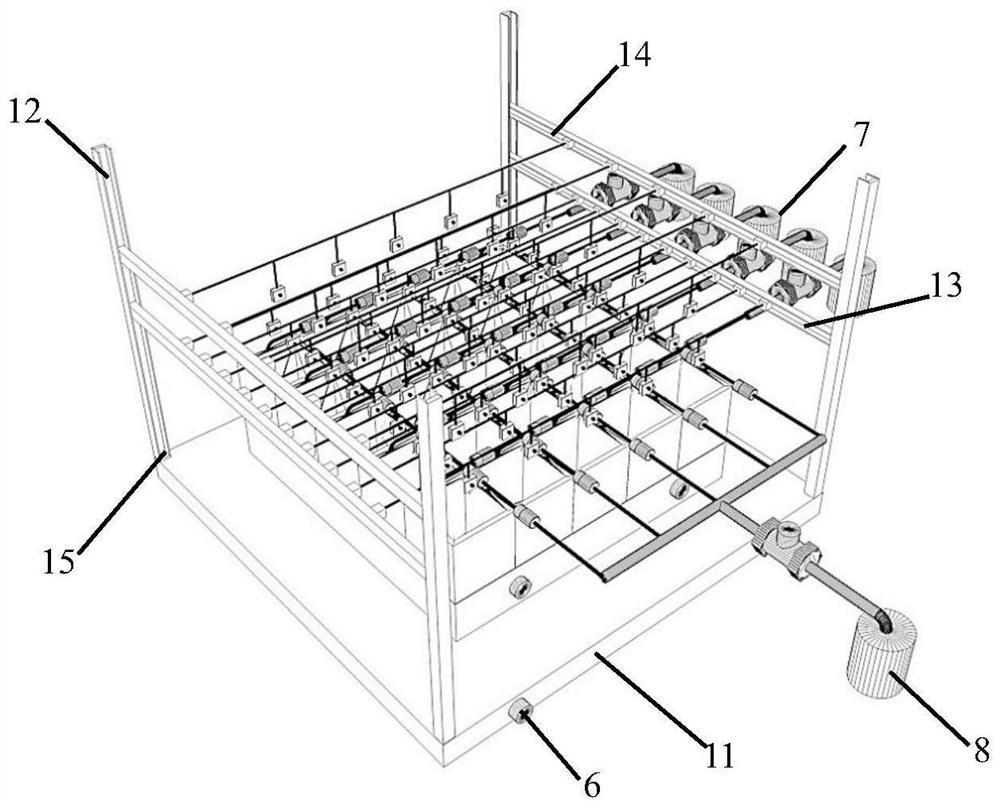

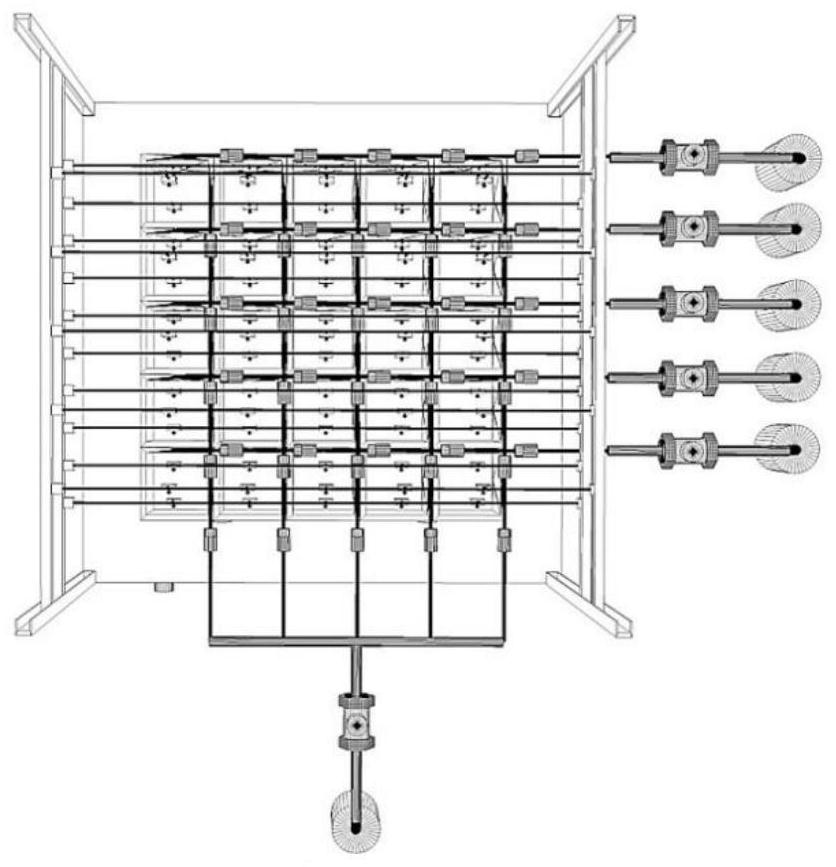

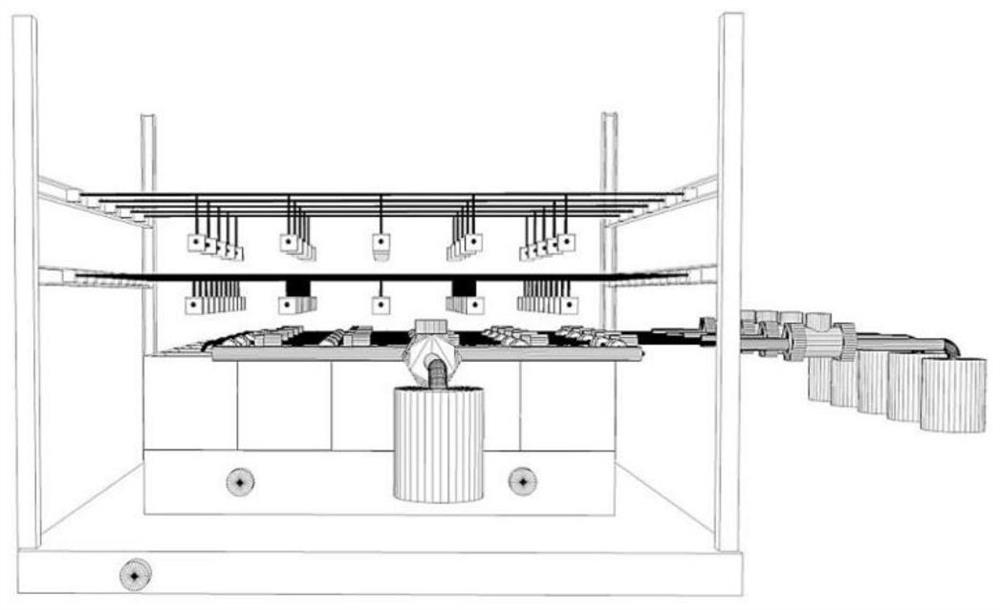

[0032] Such as Figure 1~4 As shown, the 3D automatic control high-throughput electrochemical synthesis and testing machine includes array liquid tank 1, electric pump 4, solenoid valve 9, feeding barrel 7, discharging barrel 8, magnetic stirrer 10, 3D mounting frame, anode Fixture 17, cathode fixture 18, such as Figure 5-7 As shown, the array liquid tank 1 has a length of 215mm, a width of 215mm, and a depth of 40mm. It is composed of 5×5 unit tanks, and each unit tank has two circular channels 2 that can communicate with the tank. , the unit tank is connected with a small feed tube and a small discharge tube through a circular hole 2, and an electric pump 4 is installed on the small feed tube and the small discharge tube in each unit tank, and the small discharge tube passes through a solenoid valve 9 is connected to the discharge pipe 6, the discharge pipe 6 is connected to the discharge barrel 8, the feed pipe 5 in the 5 unit tanks is connected to the respective feed bar...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is: put 10 pieces of carbon fiber cloth into the unit tank after pretreatment, select the copper sheet as the anode, and the graphite plate as the cathode, turn on the motor switch 16, and control the motor 15 to adjust the distance between the anode and the cathode. The distance between, plating solution comprises nickel chloride solution, sodium hypophosphite solution, boric acid, trisodium citrate, ferric chloride solution, is contained in 5 feed barrels 7 respectively, and wherein nickel chloride solution concentration is 0.08mol / L, the concentration of sodium hypophosphite solution is 0.2mol / L, the concentration of boric acid is 0.3mol / L, the concentration of trisodium citrate is 25g / L, and the concentration of ferric chloride solution is 0.1mol / L, and the electric pump 4 controls the flow rate and opening time control the concentration of ferric chloride solution in 10 unit tanks to be 0.03, 0.04, 0.05, 0.06,...

Embodiment 3

[0040] The difference between this embodiment and Embodiment 1 is that 25 pieces of carbon fiber cloth are put into the unit tank after pretreatment, copper sheet is selected as the cathode, platinum sheet is used as the anode, the distance between the cathode and the anode is adjusted, and the plating solution includes chlorine Nickel chloride solution, ferric chloride solution, boric acid, trisodium citrate, wherein the concentration of nickel chloride solution is 0.08mol / L, the concentration of ferric chloride solution is 0.2mol / L, the concentration of boric acid is 0.3mol / L, and the concentration of trisodium citrate is 0.08mol / L. The sodium concentration is 25g / L, the sodium hypophosphite solution concentration is 1mol / L, and the electric pump 4 controls the sodium hypophosphite solution concentration in the 25 unit tanks to be 0.06, 0.07, 0.08, 0.09, 0.1 respectively by controlling the flow rate and the opening time . Inject the volume of the plating solution, then turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com