Battery material and preparation method thereof

A technology for battery materials and electrode materials, which is applied in the preparation/purification of battery electrodes, lithium batteries, and carbon, can solve problems such as structural damage, reduction in electrical conductivity, and limit the rate performance of battery materials, to avoid oxidation and structural damage, Simple and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

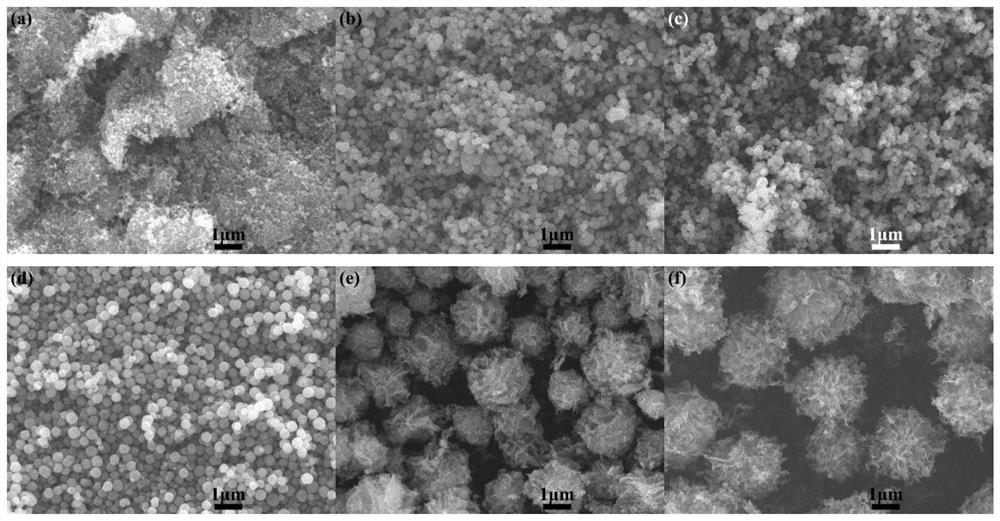

[0045] Step 1: Using iron salt and alcohol solution as raw materials, prepare C-Fe by solvothermal method 3 o 4 particles;

[0046] Step 1-1: Add 0.1 mmol of iron salt to 50 ml of ethylene glycol solution, and magnetically stir at 600 rpm / min for 60 min until the solution is transparent; then, at the same magnetic stirring speed, add 1.5 g of non-ionic polymer surface Active agent, continue to stir for 2h; then add 24mmol of amine, continue to stir at the same magnetic stirring speed for 30min, to obtain a transparent solution;

[0047] Step 1-2: Move the transparent solution finally obtained in step 1-1 into a reaction kettle and seal it, and keep it warm at 200°C for 2 hours to obtain a reaction product;

[0048] Step 1-3: Use deionized water and absolute ethanol to alternately wash the reaction product obtained in step 1-2 for 6 times, then place the washed reaction product in a vacuum drying oven, and heat it at 80°C for 24 hours to dry dry, prepared 20nm C-Fe 3 o 4 p...

Embodiment 2

[0056] Step 1: Using iron salt and alcohol solution as raw materials, prepare C-Fe by solvothermal method 3 o 4 particles;

[0057] Step 1-1: Add 0.1 mmol of iron salt to 50 ml of ethylene glycol solution, and magnetically stir at 600 rpm / min for 60 min until the solution is transparent; then, at the same magnetic stirring speed, add 1.4 g of non-ionic polymer surface Active agent, continue to stir for 2h; then add 20mmol of amine, continue to stir at the same magnetic stirring speed for 30min, to obtain a transparent solution;

[0058] Step 1-2: Move the transparent solution finally obtained in step 1-1 into a reaction kettle and seal it, and keep it warm at 180°C for 6 hours to obtain a reaction product;

[0059] Step 1-3: Use deionized water and absolute ethanol to alternately wash the reaction product obtained in step 1-2 for 6 times, then place the washed reaction product in a vacuum drying oven, and heat it at 80°C for 24 hours to dry Dry, prepared to obtain 100nm C-F...

Embodiment 3

[0066] Step 1: Using iron salt and alcohol solution as raw materials, prepare C-Fe by solvothermal method 3 o 4 particles;

[0067] Step 1-1: Add 0.1 mmol of iron salt to 50 ml of ethylene glycol solution, and magnetically stir at 600 rpm / min for 60 min until the solution is transparent; then, at the same magnetic stirring speed, add 1.25 g of non-ionic polymer surface Active agent, continue to stir for 2h; then add 17.5mmol of amine, continue to stir at the same magnetic stirring speed for 30min, to obtain a transparent solution;

[0068] Step 1-2: Move the transparent solution finally obtained in step 1-1 into a reaction kettle and seal it, and keep it warm at 170°C for 10 hours to obtain a reaction product;

[0069] Step 1-3: Use deionized water and absolute ethanol to alternately wash the reaction product obtained in step 1-2 for 6 times, then place the washed reaction product in a vacuum drying oven, and heat it at 80°C for 24 hours to dry dry, prepared 200nm C-Fe 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com