Organic compound taking fluorene as core and application of organic compound to organic light-emitting device

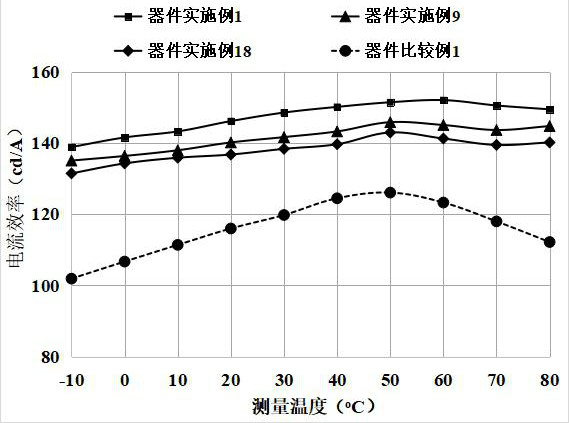

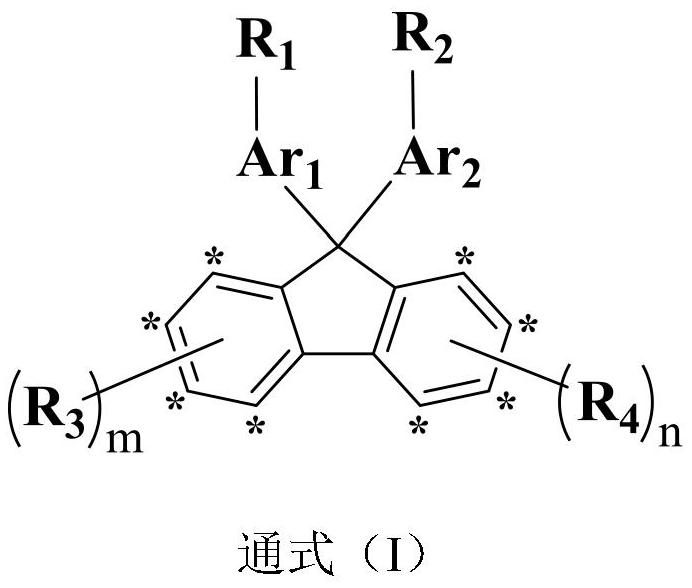

A technology of electroluminescent devices and organic compounds, applied in organic chemistry, electric solid devices, electrical components, etc., can solve the problems of different performances, and achieve the effects of not easy to aggregate, good film formation, improved current efficiency and lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: the synthesis of intermediate Q

[0053]

[0054] (1) In a 250ml four-necked flask, under a nitrogen atmosphere, add 0.05mol raw material A and 0.055mol Mg powder, 60ml tetrahydrofuran (THF), heat and reflux for 4 hours, the reaction is complete, and Grignard reagent M is generated;

[0055] (2) Weigh 0.05mol raw material B and dissolve it in 50mL tetrahydrofuran (THF), add dropwise 0.075mol Grignard reagent M, react at 60°C for 24 hours, a large amount of white Grignard salt precipitates, add saturated NHCl 4 solution until the precipitation disappears, and the Grignard salt is converted into a tertiary alcohol; after the reaction is completed, extract with 100ml ether, dry the extract with anhydrous sodium sulfate, and remove the solvent by rotary evaporation until there is no fraction, and use a mixed solvent of petroleum ether and dichloromethane (Volume ratio 3:2) was purified by a neutral silica gel column as the eluent to obtain a slightly yellow...

Embodiment 2

[0062] Embodiment 2: the synthesis of compound 2

[0063]

[0064] In a 250ml three-neck flask, under the protection of nitrogen, add 0.01mol intermediate Q-1, 0.012mol raw material D-1, 150ml toluene and stir to mix, then add 5×10 -5 mol Pd 2 (dba) 3 , 5×10 -5 mol of tri-tert-butylphosphine, 0.03mol of sodium tert-butoxide, heated to 105°C, refluxed for 24 hours, sampling plate, showed no remaining bromide, and the reaction was complete; naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated until there was no distillate , through a neutral silica gel column to obtain the target product with a purity of 99.8% and a yield of 75.6%.

[0065] Elemental analysis structure (molecular formula C 49 h 43 N): theoretical value C, 91.12; H, 6.71; N, 2.17; test value: C, 91.08; H, 6.72; N, 2.20. ESI-MS (m / z) (M+): The theoretical value is 645.89, and the measured value is 646.21.

Embodiment 3

[0066] Embodiment 3: the synthesis of compound 7

[0067]

[0068] The synthesis steps of compound 7 are similar to those of compound 2, except that raw material D-1 is replaced by raw material D-2;

[0069] Elemental analysis structure (molecular formula C 51 h 43 NO): Theoretical C, 89.31; H, 6.32; N, 2.04; O, 2.33; Tested: C, 89.26; H, 6.33; N, 2.06; ESI-MS (m / z) (M+): The theoretical value is 685.91, and the measured value is 686.37.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com