Zirconium-modified aluminum oxide material

A technology of alumina modification, which is applied in the field of alumina material preparation, can solve problems such as poor corrosion resistance and oxidation resistance, shortened service life of alumina materials, and insufficient stability of performance, so as to achieve stable performance and improve oxidation resistance , high hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

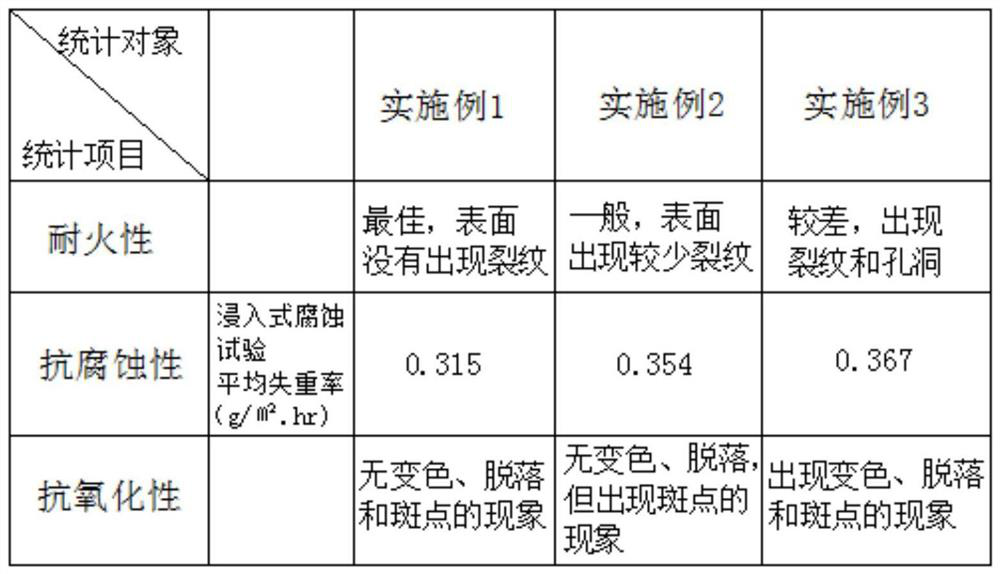

Examples

Embodiment 1

[0027] S1. First select 45 parts of alumina, 25 parts of zirconia, 15 parts of deionized water and 8 parts of modifier and put them into the reactor. The modifier is titanate. Start the reactor. The temperature of the reactor is 55°C. The stirring speed of the reactor is 200 rpm, and the stirring time is 25 minutes, and the reactor is evenly stirred for its mixture;

[0028] S2, then choose 3 parts of ferric oxide, 2 parts of chromium oxide, 20 parts of silicon dioxide, 10 parts of rare earth elements, 7 parts of chromium ore, 5 parts of magnesia and 0.6 part of compatibilizer and drop into the reactor, the rare earth elements It is the combination of lanthanum and cerium, the compatibilizer is the combination of magnesium hydroxide and talcum powder, the stirring speed of the reactor is 250 rpm, and the stirring time is 20 minutes. After mixing evenly, finally mix 4 parts of antioxidant and 0.3 part of Put the defoamer into the reactor for mixing, the defoamer is tributyl pho...

Embodiment 2

[0031] S1. First select 40 parts of alumina, 20 parts of zirconia, 10 parts of deionized water and 6 parts of modifier and put them into the reactor. The modifier is phosphate. Start the reactor. The temperature of the reactor is 50°C. The stirring speed of the kettle is 150 rpm, and the stirring time is 20 minutes, and the reaction kettle is evenly stirred for its mixture;

[0032] S2, then choose 2 parts of ferric oxide, 1 part of chromium oxide, 15 parts of silicon dioxide, 8 parts of rare earth elements, 5 parts of chromium ore, 3 parts of magnesia and 0.5 part of compatibilizer and drop into the reactor, the rare earth elements It is yttrium, the compatibilizer is calcium carbonate, the stirring speed of the reactor is 200 rpm, and the stirring time is 15 minutes. After mixing evenly, finally 3 parts of antioxidant and 0.2 part of defoamer are dropped into the reactor and mixed. Antifoaming agent is phosphoric acid ester, and antioxidant is 4,4'-bis(2,2-dimethylbenzyl) di...

Embodiment 3

[0035] S1. First select 50 parts of alumina, 30 parts of zirconia, 20 parts of deionized water and 10 parts of modifier and put them into the reactor. The modifier is silane. Start the reactor. The temperature of the reactor is 60°C. The stirring speed is 250 rpm, and the stirring time is 30 minutes, and the reaction kettle is evenly stirred for its mixture;

[0036]S2, then choose 4 parts of ferric oxide, 3 parts of chromium oxide, 25 parts of silicon dioxide, 12 parts of rare earth elements, 9 parts of chromium ore, 7 parts of magnesia and 0.7 part of compatibilizer and drop into the reactor, the rare earth elements It is the combination of neodymium, europium and yttrium, and the compatibilizer is the combination of talcum powder, calcium carbonate and barium sulfate. The stirring speed of the reactor is 300 rpm, and the stirring time is 25 minutes. The oxidizing agent and 0.4 parts of defoaming agent are put into the reactor for mixing, the antioxidant is N-phenyl-N'-isopr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com