Preparation method of annular radiation orientation magnet

A radiation orientation and ring technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of easy cracking, low magnet qualification rate, difficulty in improving the residual magnetism of radiation ring magnets, etc., and achieve heat resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

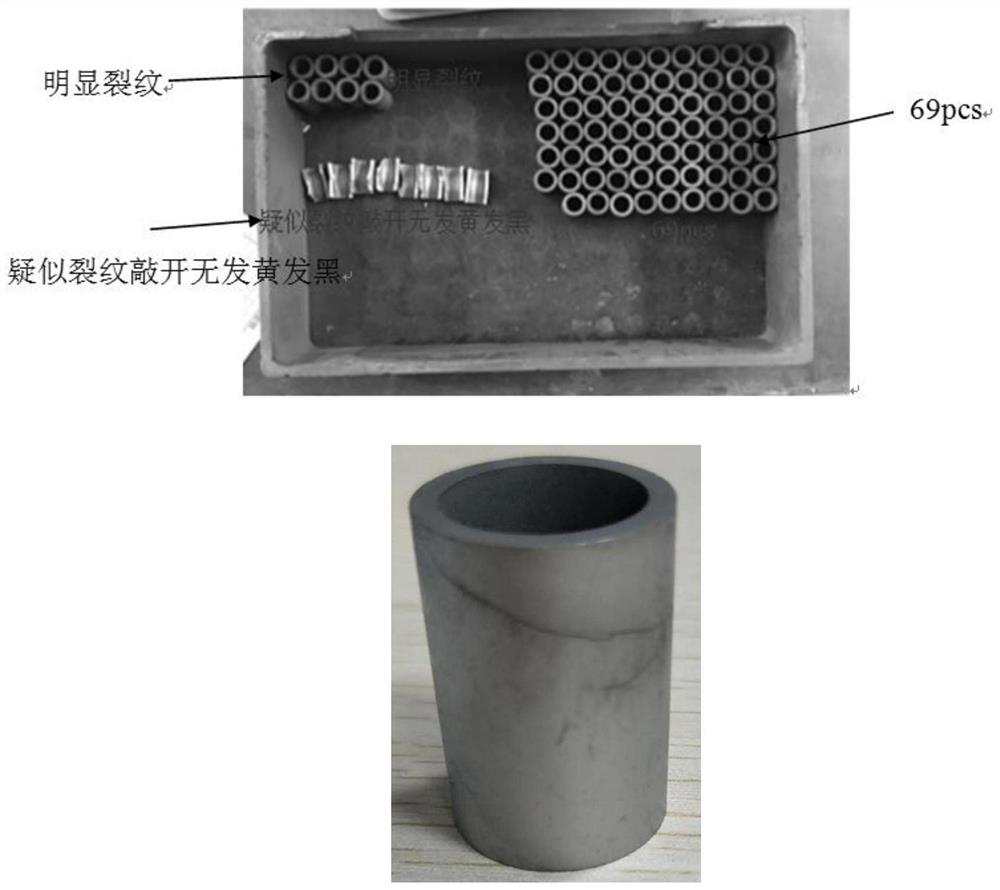

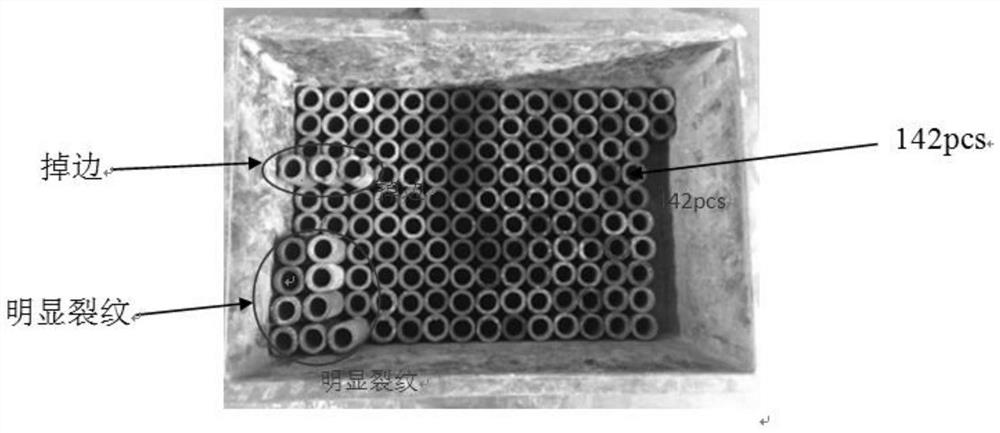

[0028] In the process of preparing the ring-shaped radiation orientation magnet, the applicant firstly prepared the radiation ring NdFeB blank. The preparation method of the radiation ring NdFeB blank is not particularly limited in this application, and is carried out according to the technical means well known to those skilled in the art. That is, as an example, it can be prepared in sequence according to the process of proportioning-smelting-milling-powder radiation orientation compression molding-vacuum sintering. The radiant ring NdFeB blank described in this application is the radiant ring NdFeB blank well known to those skilled in the art. In a specific embodiment, the specific composition of the radiant ring NdFeB blank includes: Pr-Nd: 28wt% ~33wt%; Nb: 0~5wt%; B: 0.5wt%~2.0wt%; Al: 0~3.0wt%; Cu: 0~2wt%; Co: 0~3wt%; Ga: 0~2wt%; Gd: 0-2wt%; Ho: 0-2wt%; Zr: 0-2wt%; the balance is Fe. In order to facilitate the diffusion of the radiant ring NdFeB blank, the present appli...

Embodiment 1

[0036] Prepare Tb80wt%-Al8wt%-Ga3.9wt%-Cu8wt%-H0.1wt% powder and add it to ethanol to form a suspension;

[0037] The 42SH magnet blank prepared by the steps of smelting, powder making, molding and sintering is processed into a semi-finished product of D22.5*d18.5*30.5, and the semi-finished product is processed and degreased to make the surface clean and smooth; The processed semi-finished product is soaked in the suspension and coated so that the surface is evenly coated with a layer of diffusion source, and then the semi-finished product is placed in the sintering box, and the sintering box with the semi-finished product is placed in the diffusion furnace and vacuumized to 10 -2 Below Pa, carry out in argon gas at a temperature of 700-950°C for 2-15 hours, and then perform a low-temperature tempering heat treatment at a temperature of 450-550°C for 3-7.5 hours to obtain an NdFeB magnet.

[0038] The preparation method of the 42SH magnet blank is as follows: Pr-Nd: 32.4%; B...

Embodiment 2

[0043] Prepare Tb90wt%-Al5wt%-Ga2.9wt%-Cu2wt%-H0.1wt% powder and add it to ethanol to form a suspension;

[0044] Preparation (45H raw material ratio): Pr-Nd: 31.5%; B: 0.98%; Zr: 0.15%; Cu: 0.1%; Co: 1%; Al: 0.35%; Ga: 0.1%; the balance is Fe. The 45H magnet blank prepared by smelting, powder making, molding, and sintering steps is processed into a semi-finished product of D22.5*d18.5*30.5, and the semi-finished product is processed and degreased to make the surface clean and smooth; then the pretreated The final semi-finished product is soaked in the suspension and coated so that the surface is evenly coated with a layer of diffusion source. Then the semi-finished product is placed in the sintering box, and the sintering box with the product is placed in the diffusion furnace. Vacuum to 10 -2 Below Pa, carry out in argon gas at a temperature of 700-950°C for 2-15 hours, and then perform a low-temperature tempering heat treatment at a temperature of 450-550°C for 3-7.5 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com