Method for preparing monoatomic cluster Fe-N co-doped single-walled carbon nanotube electro-catalytic membrane electrode

A technology of single-walled carbon nanotubes and carbon nanotube films, applied in the field of preparing single-atom cluster Fe-N co-doped single-walled carbon nanotube electrocatalytic thin film electrodes, can solve the problem of carbon nanotube-based electrocatalysts relying on organic bonding Agents and other issues, to achieve the effect of excellent performance, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

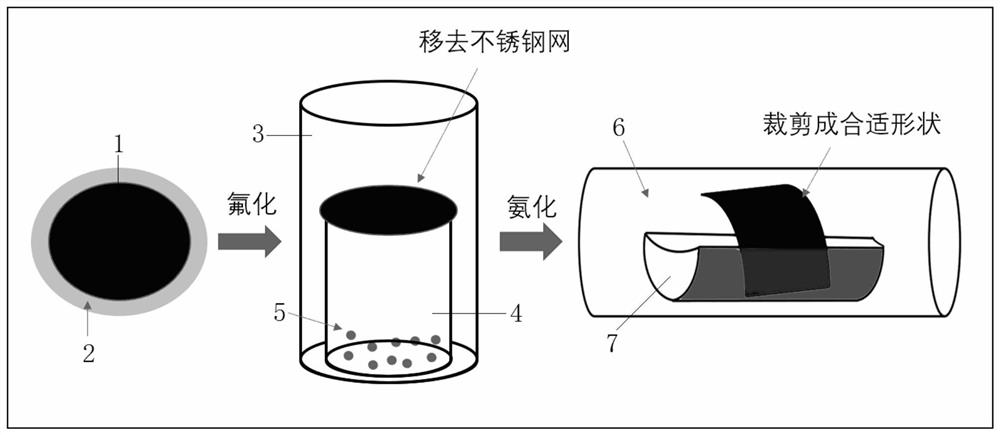

[0041] In this embodiment, the method for preparing a monoatomic cluster Fe-N co-doped single-walled carbon nanotube electrocatalytic thin film electrode comprises the following steps:

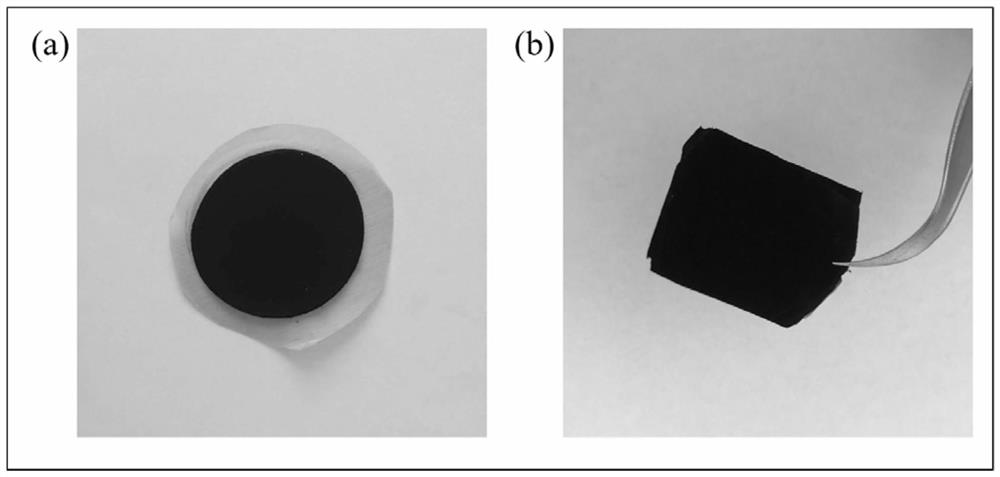

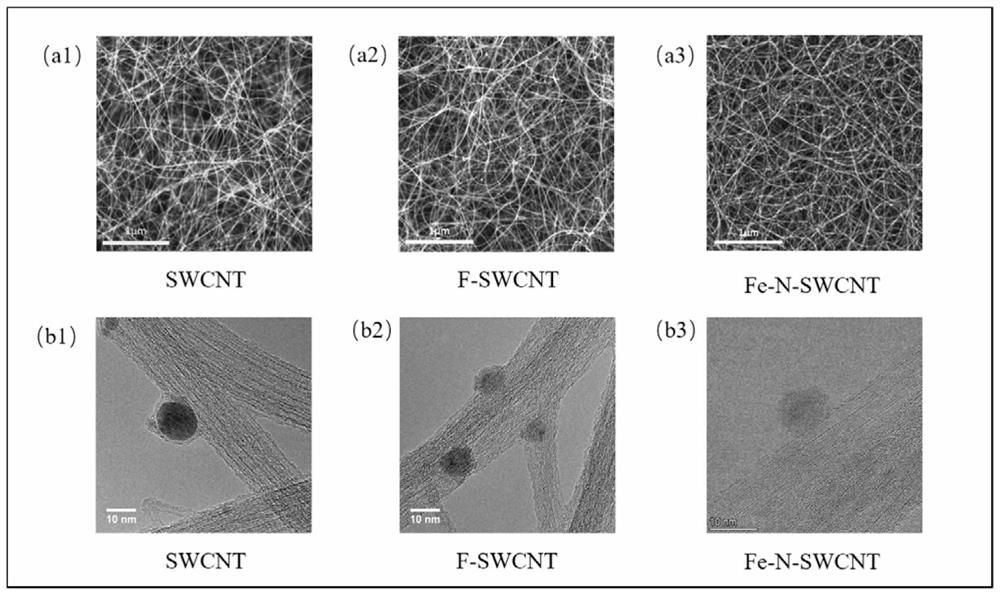

[0042] 1. If figure 2 As shown, a high-purity single-walled carbon nanotube film was prepared by floating catalyst chemical vapor deposition, and a single-walled carbon nanotube film with a thickness of 250 microns and a G / D ratio of 120 was obtained by adjusting the collection time; It can be seen that the single-walled carbon nanotubes are mainly intertwined in the form of tube bundles to form a self-supporting carbon nanotube film, and a large number of microporous structures are formed between the intertwined tube bundles, which is beneficial to the material transport during the reaction process. From the transmission electron microscope photos, it can be seen that the Fe nanoparticle catalyst used to grow carbon nanotubes is covered by carbon layers and embedded in the tube bundles. The...

Embodiment 2

[0047] In this embodiment, the difference from Embodiment 1 is:

[0048] (1) Using the same preparation and collection method of the single-wall carbon nanotube film as in Example 1, by adjusting the collection time, a single-wall carbon nanotube film with a thickness of 100 microns was obtained. Using the same fluorination and ammoniation treatment methods as in Example 1, the single-walled carbon nanotube film was subjected to gas phase treatment. The fluorination temperature is 150° C. and the time is 6 hours, and the fluorine / carbon molar ratio of the fluorinated carbon nanotube film is 14.9%. The ammoniation temperature is 700° C., the time is 0.5 h, the flow rate of ammonia gas is 50 sccm, and after ammonia treatment, the molar ratio of nitrogen / carbon in the carbon nanotube film is 3.3%.

[0049] (2) Same as Step 2 of Example 1, the oxygen reduction performance test was carried out on the treated single-walled carbon nanotube film. The obtained oxygen reduction curve ...

Embodiment 3

[0051] In this embodiment, the difference from Embodiment 1 is:

[0052] (1) Using the same preparation and collection method of the single-walled carbon nanotube film as in Example 1, by adjusting the collection time, a single-walled carbon nanotube film with a thickness of 500 microns was obtained. Using the same fluorination and ammoniation treatment methods as in Example 1, the single-walled carbon nanotube film was subjected to gas phase treatment. The fluorination temperature is 220° C., the time is 18 hours, and the fluorine / carbon molar ratio of the fluorinated carbon nanotube film is 25.4%. The ammoniation temperature was 750° C., the time was 2 hours, and the flow rate of ammonia gas was 200 sccm. After ammonia gas treatment, the molar ratio of nitrogen / carbon in the carbon nanotube film was 5.6%.

[0053] (2) Same as Step 2 of Example 1, the oxygen reduction performance test was carried out on the treated single-walled carbon nanotube film. The obtained oxygen red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com