Method for immobilizing MXene by covalent bonding of ionic liquid and product thereof

An ionic liquid and covalent bonding technology, applied in the direction of nitrogen compounds, carbon compounds, chemical instruments and methods, etc., can solve the problems of easy redeposition of MXene materials, high energy consumption of modification methods, and few active sites, etc., to achieve Achieve large-scale industrial production, long reaction time, and low loss of ionic liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

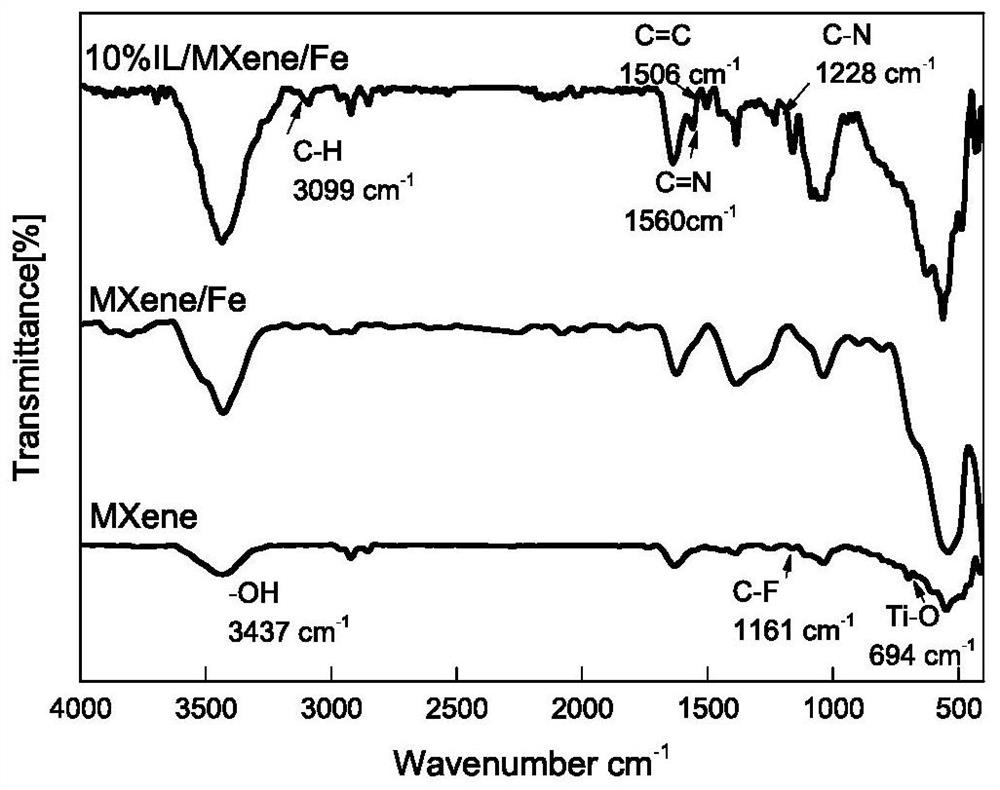

[0028] The present invention provides a preparation method of MXene covalently bonded and immobilized by ionic liquid, which includes the following steps:

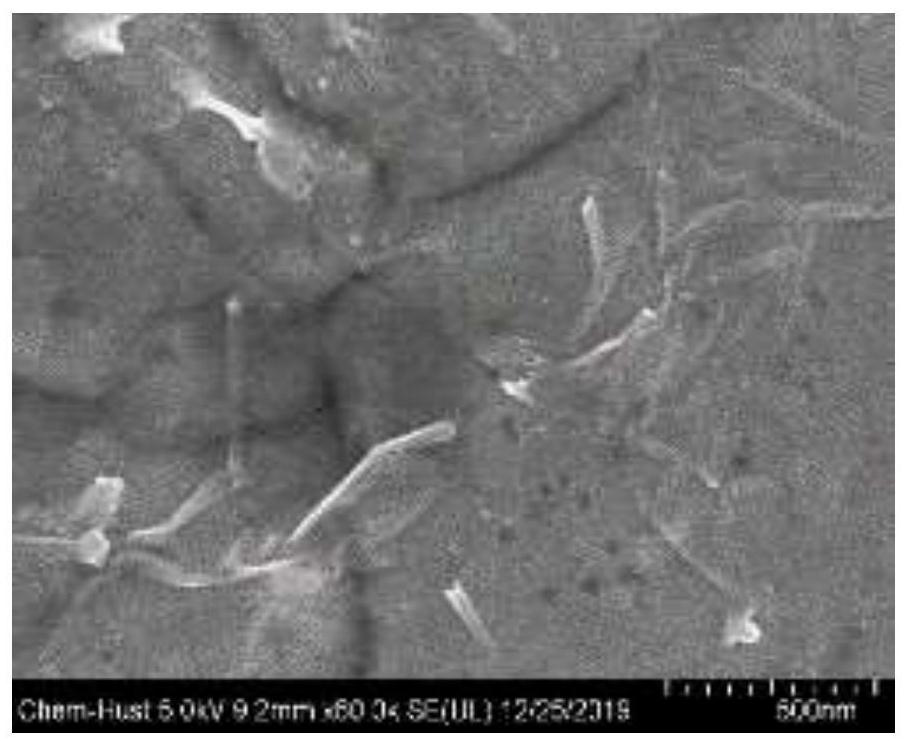

[0029] Step 1: Preparation of MXene nanosheets: adding MAX phase material into a fluorine-containing solution for etching and ultrasound to obtain a dispersion of MXene nanosheets.

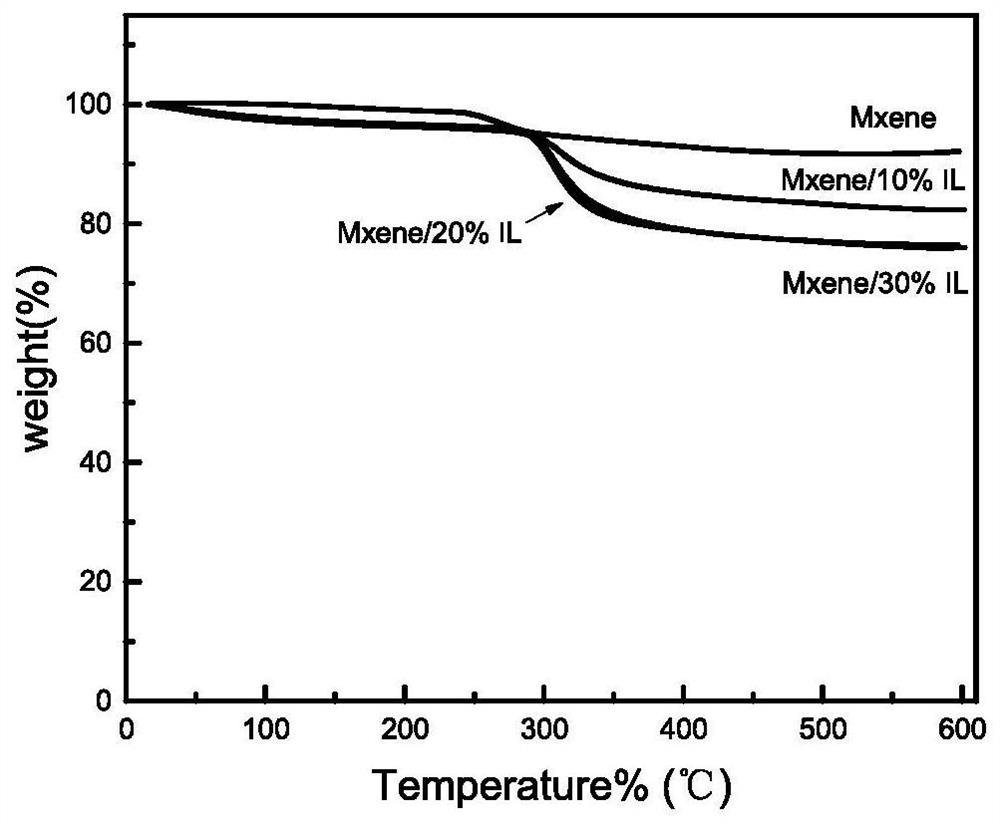

[0030] Step 2: Take a certain concentration of MXene nanosheet dispersion, ultrasonically disperse uniformly, pass in inert gas, seal, and add an ionic liquid monomer containing unsaturated double bonds to cause radiation grafting reaction with MXene.

[0031] In step three, the product obtained in step two is centrifuged and washed to obtain an ionic liquid covalently bonded and immobilized MXene material.

[0032] The general formula of MXene mentioned in step one is M n+1 X n T x (n=1-3), where M is an early transition metal (Sc, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, etc.), X is carbon and / or nitrogen, and Tx is a surface terminating group ( Such as OH, O...

Embodiment 1

[0045] The preparation method of ionic liquid covalently immobilized MXene includes the following steps:

[0046] Step 1. Preparation of MXene nanosheets: add 1g LiF to a 50mL PTFE container, add 20mL 9MHCl, and stir for 30min at room temperature to obtain a colorless and transparent solution. Weigh 1g Ti3AlC2 and slowly add it to the above solution in batches. Stir at °C for 48 hours, centrifuge the obtained reaction solution (3500 rpm, 5 min) and wash until the pH of the supernatant decanted after centrifugation is above 5, preferably the pH is 5-7, and the precipitate is taken. Add 80mL H2O for ice bath ultrasound (600W, 20min) to collect the upper layer of black rice dumpling liquid, which is a small layer of Ti3C2 Tx dispersion. In order to obtain more small layer of Ti3C2Tx, repeatedly add water to the multilayer Ti3C2Tx and shake the upper layer. Black rice dumpling liquid, preferably, repeat 3 to 5 times to combine the collected black rice dumpling liquid. Obtain single-...

Embodiment 2

[0051] An improvement is made on the basis of the method provided in Example 1, except that the concentration of the ionic liquid is 20 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com