Nano cellulose and preparation method thereof

A technology of nanocellulose and cellulose, applied in the field of materials, can solve the problems of intractable hydrolysis products, strong corrosiveness of reaction equipment, and difficult recycling of reaction liquids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

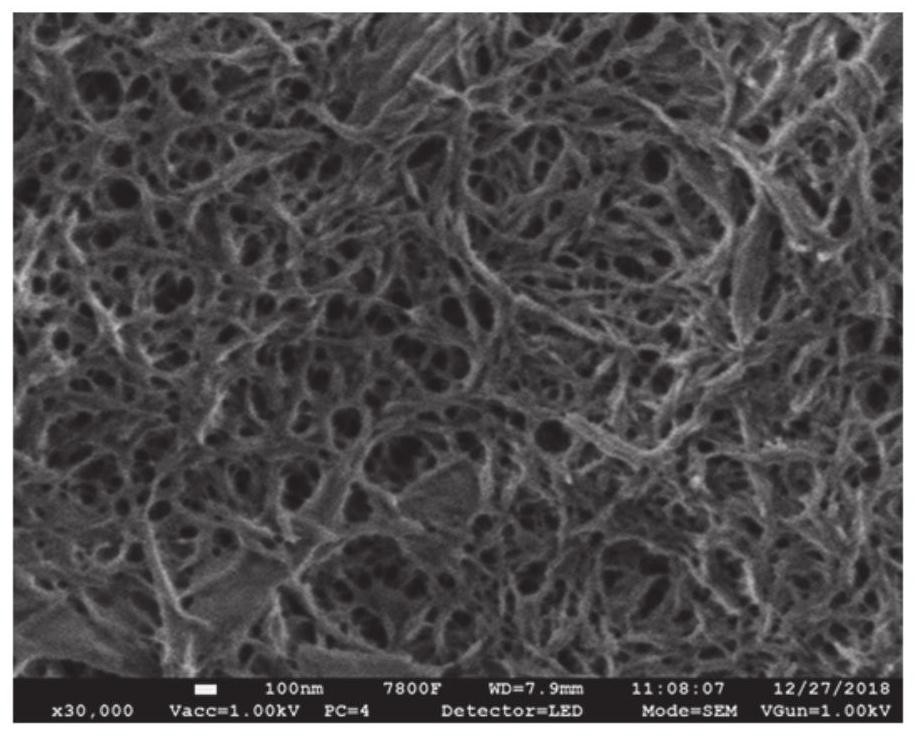

Image

Examples

Embodiment 1

[0037] Weigh the cellulose pulp of 0.5g pine wood and add in the reaction kettle, add formic acid and water simultaneously, the total volume of formic acid and water is 9.6ml, wherein contains 0.5g formic acid and 9.5g water, stirs and makes it fully mix. Seal the reaction kettle, close the gas inlet and outlet, heat up to 180°C by electric heating under 600rpm magnetic stirring, and react for 600min. After the reaction, the reactor was cooled to room temperature with ice water, the stirring was stopped, and the reaction solution was centrifuged to obtain the solid nanocellulose part and the recovered reaction solution, and the solid was washed 3 times with deionized water until neutral. The nanocellulose product is obtained by drying the nanocellulose solid at 30° C. for 36 hours in a vacuum box with a vacuum degree of -0.1 MPa. The recovered reaction solution can be further recycled to prepare nanocellulose.

[0038] The nanocellulose labeled as #1 sample was obtained with ...

Embodiment 2

[0050] Weigh 1g of pine wood cellulose pulp into the reactor, add acetic acid and water at the same time, the total volume of acetic acid and water is 21.0ml, which contains 1.5g acetic acid and 20.1g water, stir to make it fully mixed. Seal the reaction kettle, close the air inlet and outlet, and raise the temperature to 160°C by electric heating under 800rpm magnetic stirring, and react for 1000min. After the reaction, the reactor was cooled to room temperature with ice water, the stirring was stopped, and the reaction solution was centrifuged to obtain the solid nanocellulose part and the recovered reaction solution, and the solid was washed 5 times with deionized water until neutral. The nanocellulose product is obtained by drying the nanocellulose solid at -20° C. for 12 hours in a freeze-drying oven with a vacuum degree of -0.1 MPa. The recovered reaction solution can be further recycled to prepare nanocellulose.

[0051] It was obtained that the yield of nanocellulose ...

Embodiment 3

[0053] Weigh the cellulose pulp of 0.6g pine and add in the reaction kettle, add propionic acid and water simultaneously, the total volume of propionic acid and water is 10.4ml, wherein contains 0.8g propionic acid and 10.0g water, stirs and makes it fully mix. Seal the reaction kettle, close the air inlet and outlet, heat up to 150°C by electric heating under 800rpm magnetic stirring, and react for 800min. After the reaction, the reactor was cooled to room temperature with ice water, the stirring was stopped, and the reaction liquid was centrifuged to obtain the solid nanocellulose part and the recovered reaction liquid, and the solid was washed 4 times with deionized water until neutral. The nanocellulose product is obtained by drying the nanocellulose solid at -20° C. for 12 hours in a freeze-drying oven with a vacuum degree of -0.1 MPa. The recovered reaction solution can be further recycled to prepare nanocellulose.

[0054] The yield of nanocellulose was 89.7%, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com