Method for synthesizing granular activated carbon catalyst while self-activating coconut shells under catalysis of calcium

A technology for synthesizing particles and self-activation, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of uneven dispersion of metal oxides, complicated preparation steps, Problems such as specific surface area and pore volume decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

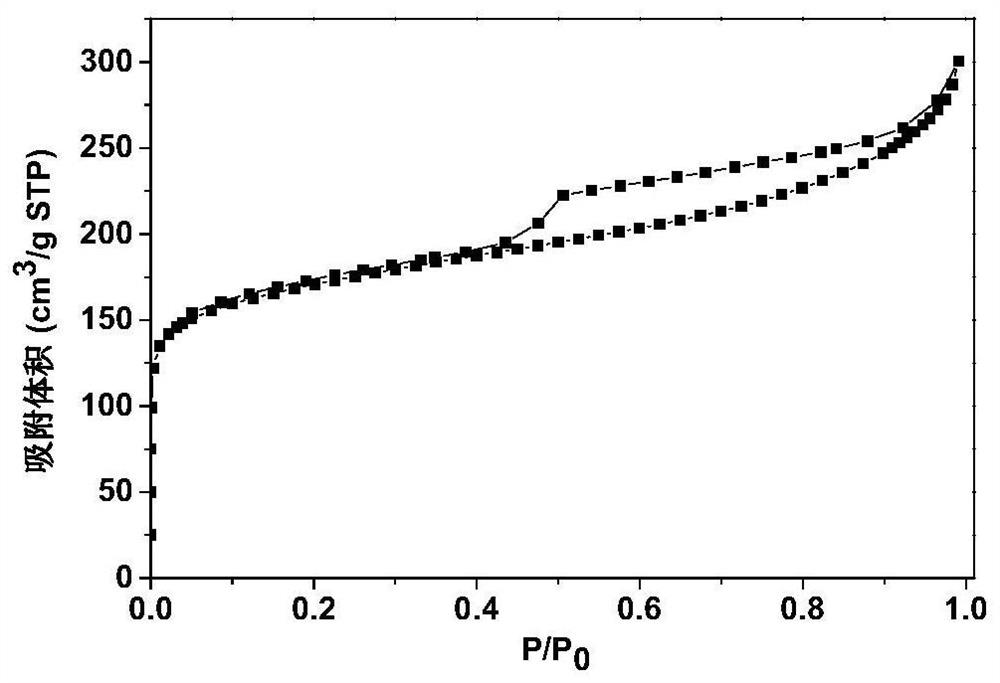

Embodiment 1

[0026] Mix dry coconut shells with a particle size of 0.18mm~0.28mm and 0.5mol / L lanthanum nitrate solution at a solid-to-liquid ratio of 1g:1.5mL, vacuum impregnate for 25 hours, and vacuum dry; place Ca-coir in the middle of the tube furnace , close the inlet valve, and after the tube furnace is pumped to vacuum, close the outlet valve, raise the temperature to 800°C, control the pressure at 0.12~0.13MPa by adjusting the outlet valve, and activate the catalytic pyrolysis for 4 hours; feed nitrogen into the tube furnace (200mL / min), heated to 900°C and calcined under normal pressure for 2h to prepare a hierarchical porous carbon-based CaO catalyst. The specific surface area of the catalyst is 712.3m 2 / g, the total pore volume is 0.509cm 3 / g, the mesoporosity is 47.47%, and the average particle size of nano-CaO is 23.2nm.

Embodiment 2

[0028] Mix dry coconut shells with a particle size of 0.18mm~0.28mm and 0.5mol / L lanthanum nitrate solution at a solid-to-liquid ratio of 1g:1.5mL, vacuum impregnate for 24 hours, and vacuum dry; place Ca-coir in the middle of the tube furnace , close the inlet valve, and after the tube furnace is pumped to vacuum, close the outlet valve, raise the temperature to 800°C, control the pressure at 0.12~0.13MPa by adjusting the outlet valve, and activate the catalytic pyrolysis for 2 hours; feed nitrogen into the tube furnace (200mL / min), heated to 900°C and calcined under normal pressure for 2h to prepare a hierarchical porous carbon-based CaO catalyst.

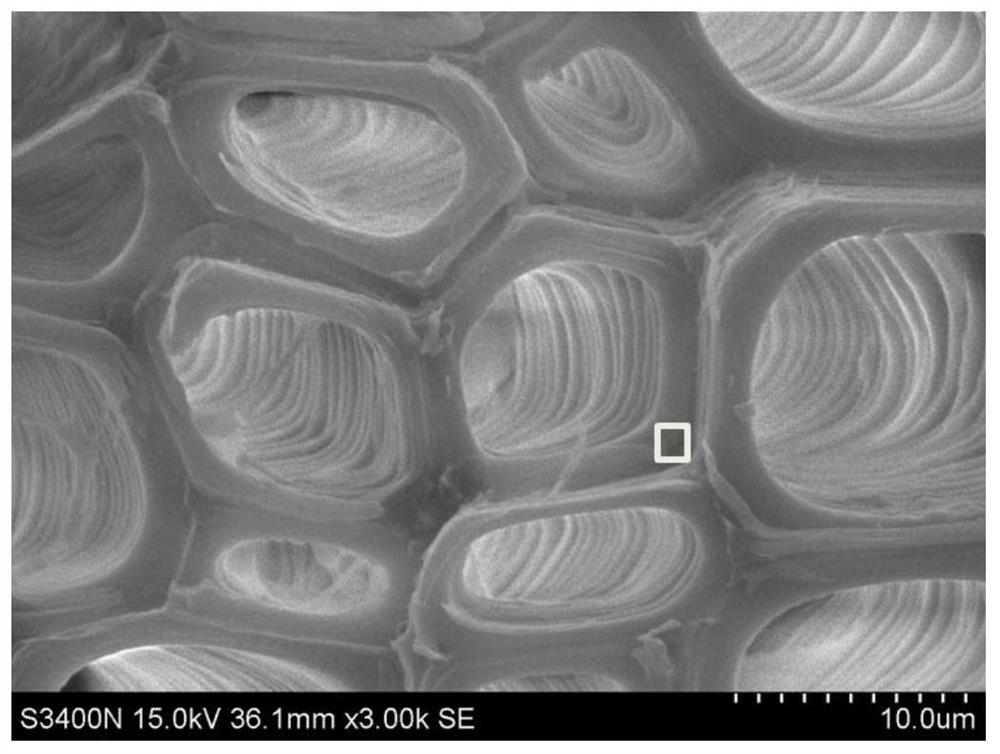

[0029] figure 1 After the Ca-coconut shell obtained in this implementation case is cut and processed, the scanning electron microscope-X-ray energy spectrum analysis diagram of the inner cell wall shows no obvious change in the inner cell wall, and the elemental analysis at the box is detected to contain 2.77wt% lanthanum element...

Embodiment 3

[0037] Mix dry coconut shells with a particle size of 0.18mm~0.28mm and 0.5mol / L lanthanum nitrate solution at a solid-to-liquid ratio of 1g:1.5mL, vacuum impregnate for 24 hours, and vacuum dry; place Ca-coir in the middle of the tube furnace , nitrogen gas (200mL / min) was introduced into the tube furnace, the temperature was raised to 800°C for 2 h, and the temperature was raised to 900°C for 2 h under normal pressure to prepare the carbon-based CaO catalyst. The specific surface area of the catalyst is 451.5m 2 / g, the total pore volume is 0.232cm 3 / g, the mesoporosity is 20.00%, and the average particle size of nano-CaO is 7.6nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com