Preparation method of copper-based composite metal catalyst

A metal catalyst, copper-based composite technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy sintering, high cost, and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

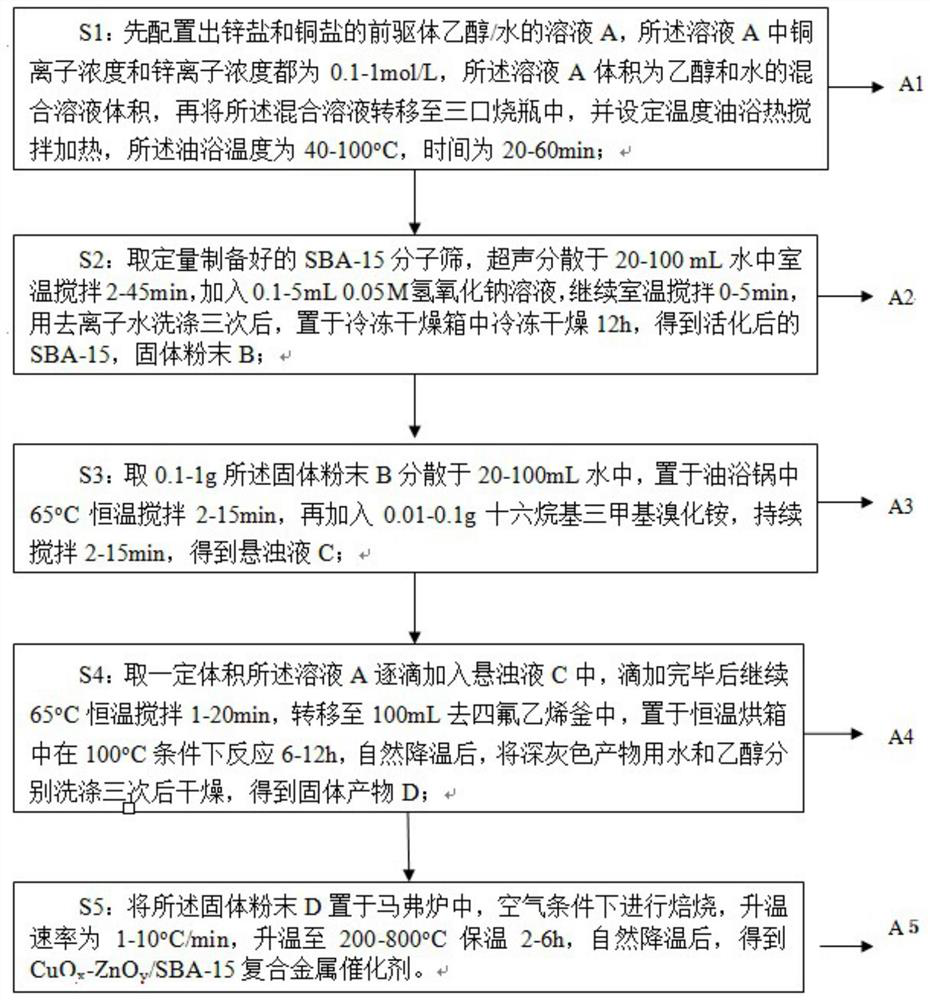

[0027] Such as figure 1 Shown, a kind of preparation method of copper-based composite metal catalyst, described copper-based composite metal catalyst is used in methanol water reforming hydrogen production technology, wherein SBA-15 molecular sieve is carrier, contains SiO in SBA-15 molecular sieve 2 and a small amount of metal oxide, ZnO is a cocatalyst, and CuO is a main catalyst, specifically including the following steps:

[0028] S1: First configure the solution A of zinc salt and copper salt precursor ethanol / water, the copper ion concentration and zinc ion concentration in solution A are both 0.1-1mol / L, the volume of solution A is the volume of the mixed solution of ethanol and water, Then transfer the mixed solution to a three-necked flask, and set the temperature of the oil bath to stir and heat, the temperature of the oil bath is 40-100°C, and the time is 20-60min;

[0029] S2.: Take the quantitatively prepared SBA-15 molecular sieve, ultrasonically disperse it in ...

Embodiment 2

[0052] (1) Dissolve 5g of copper nitrate and 1.6g of zinc nitrate in a mixed solution of 40mL of water + 60mL of ethanol, place in an oil bath at a constant temperature of 75°C and stir for 20min to obtain a mixed solution A;

[0053] (2) Ultrasonic dissolve 2g of SBA-15 prepared into 100mL water and stir at room temperature for 15min, add 5mL of 0.05M sodium hydroxide solution, continue to stir at room temperature for 1min, wash with deionized water three times, and place in a freeze-drying box to freeze-dry 12h, obtain activated SBA-15, solid powder B;

[0054] (3) Take the above 0.8g of solid powder B and disperse it in 100mL of water, place it in an oil bath at 65°C and stir for 15min at a constant temperature, then add 0.05g of hexadecyltrimethylammonium bromide, and keep stirring for 5min to obtain a suspension C;

[0055] (4) Take 10mL of the above-mentioned solution A and add it to the suspension C dropwise. After the dropwise addition, continue to stir at a constant ...

Embodiment 3

[0058] (1) Dissolve 6g of copper nitrate and 1.8g of zinc nitrate in a mixed solution of 40mL of water + 60mL of ethanol, place in an oil bath at a constant temperature of 75°C and stir for 20min to obtain a mixed solution A;

[0059] (2) Ultrasonic dissolve 2g of SBA-15 prepared into 100mL water and stir at room temperature for 15min, add 5mL of 0.05M sodium hydroxide solution, continue to stir at room temperature for 1min, wash with deionized water three times, and place in a freeze-drying box to freeze-dry 12h, obtain activated SBA-15, solid powder B;

[0060] (3) Take the above 0.8g of solid powder B and disperse it in 100mL of water, place it in an oil bath at 65°C and stir for 15min at a constant temperature, then add 0.05g of hexadecyltrimethylammonium bromide, and keep stirring for 5min to obtain a suspension C;

[0061] (4) Take 10mL of the above-mentioned solution A and add it to the suspension C dropwise. After the dropwise addition, continue to stir at a constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com