Method and device for preparing olefin through catalytic conversion of petroleum hydrocarbon raw material

A technology for catalytic conversion and olefin production, which is used in hydrocarbon cracking to produce hydrocarbons, chemical instruments and methods, petroleum industry, etc., and can solve problems such as high reaction temperature, reduced catalytic cracking reaction effect, and reduced catalyst cracking activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

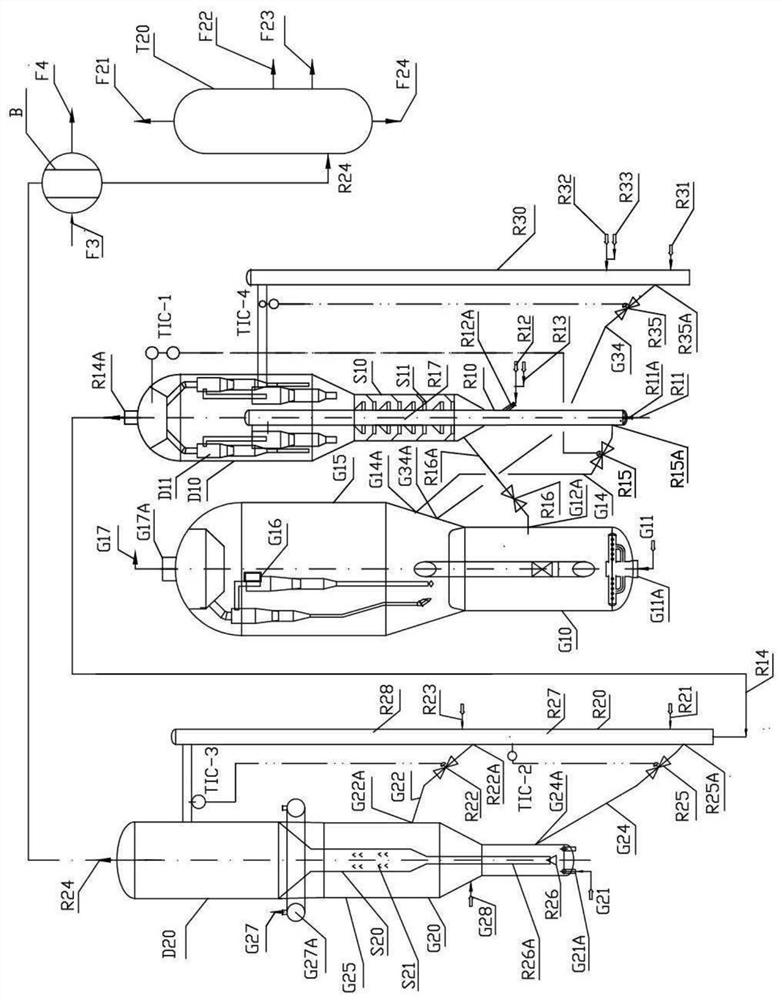

[0070] The method for producing olefins by catalytic conversion of petroleum hydrocarbon raw materials in this embodiment adopts figure 1 The catalytic conversion device shown is equipped with a first reaction regeneration system and a second reaction regeneration system, and uses heavy petroleum hydrocarbons and hydrocracking tail oil as raw materials. In specific implementation, heavy petroleum hydrocarbons can be vacuum wax oil, residue oil, coker wax oil, deasphalted oil, hydrogenated wax oil, hydrogenated residual oil, hydrogenated catalytic diesel oil, crude oil, condensate oil, or a mixture thereof, with a boiling point higher than 320°C; in the present invention, hydrocracking Tail oil is a well-known technical term in the art, and its properties are related to the feedstock oil used in hydrocracking. In practice, the BMCI value of hydrocracking tail oil capable of catalytic conversion is less than or equal to 20;

[0071] The first reaction regeneration system is equi...

Embodiment 1

[0082] A factory uses heavy petroleum hydrocarbons and hydrocracking tail oil as raw materials to catalytically convert olefins, using equipment and processes such as figure 1 As shown, the implementation parameters are as follows:

[0083] The reaction materials are atmospheric heavy oil and hydrocracking tail oil, and the hydrocracking tail oil is fed separately. Atmospheric heavy oil, density 0.91, hydrogen content 12.8% (weight), residual carbon 3.8%, saturated hydrocarbon content 61%, Ni less than 4.0ppm, V less than 0.1ppm; hydrocracking tail oil density 0.82, BMCI value 10.6; hydrogenation The amount of cracked tail oil accounts for 10% of the raw oil;

[0084] Atmospheric heavy oil preheating temperature is 220°C; hydrocracking tail oil temperature is 300°C;

[0085] The reaction conditions of the first reactor: the reaction temperature (i.e. the reaction temperature at the outlet of the reactor) TIC-1 is 530°C, the reaction time is 1.0s (seconds); the temperature of...

Embodiment approach 2

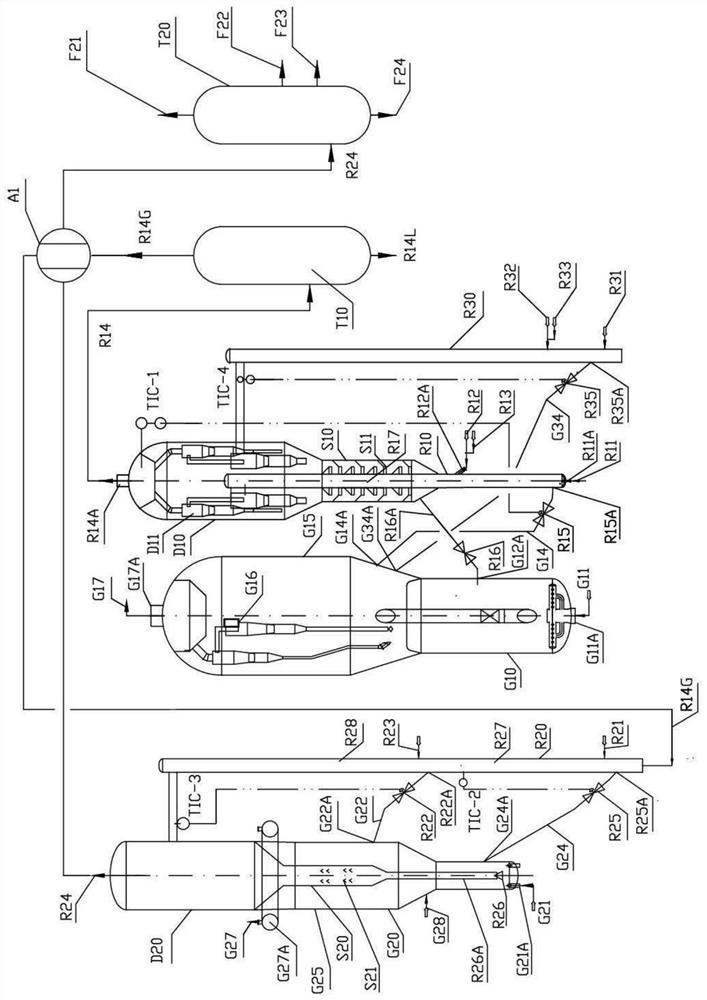

[0098] The method for producing olefins by catalytic conversion of petroleum hydrocarbon raw materials in this embodiment adopts figure 2 The catalytic conversion device shown is provided with a first reaction regeneration system and a second reaction regeneration system;

[0099]The second reaction system product R24 drawn from the top outlet of the second settler D20 enters the fractionation tower T20 after heat exchange and cooling by the heat exchanger A1, and the second reaction system product R24 is separated into liquefied gas and dry gas gas product F21, gasoline group Fraction F22, light cycle oil component F23 and tower bottom heavy component F24;

[0100] A logistics pipeline is arranged between the first reaction gas product outlet R14A and the bottom of the second reactor R20, and the first reaction system product heavy component separation tower T10 is arranged on the logistics pipeline at the same time; the first reaction system product R14 first passes through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear index | aaaaa | aaaaa |

| Wear index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com