Light-stable polypropylene resin composition and preparation method thereof

A technology of polypropylene resin and polypropylene copolymer, which is applied in the field of light-stabilized polypropylene resin composition and its preparation, and can solve problems such as high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

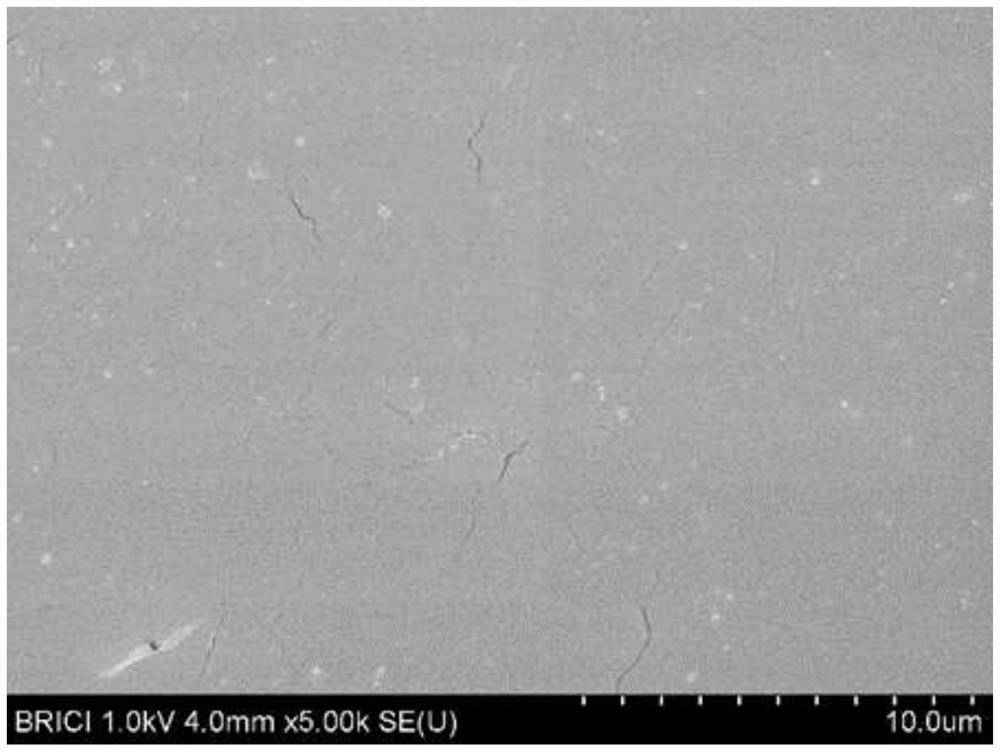

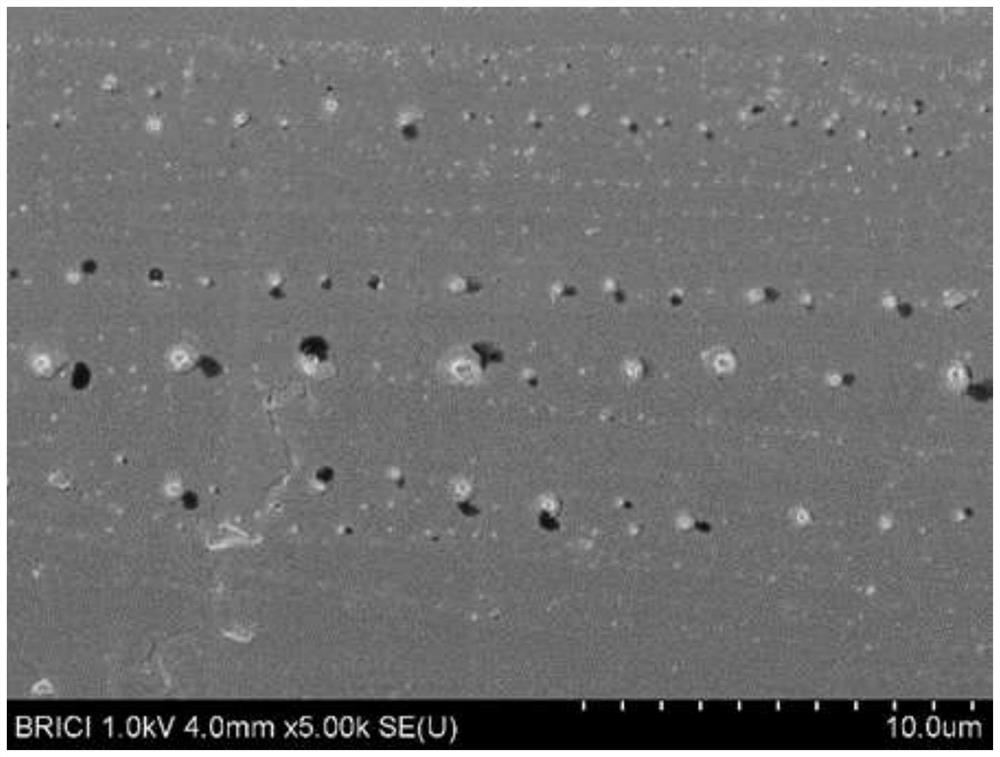

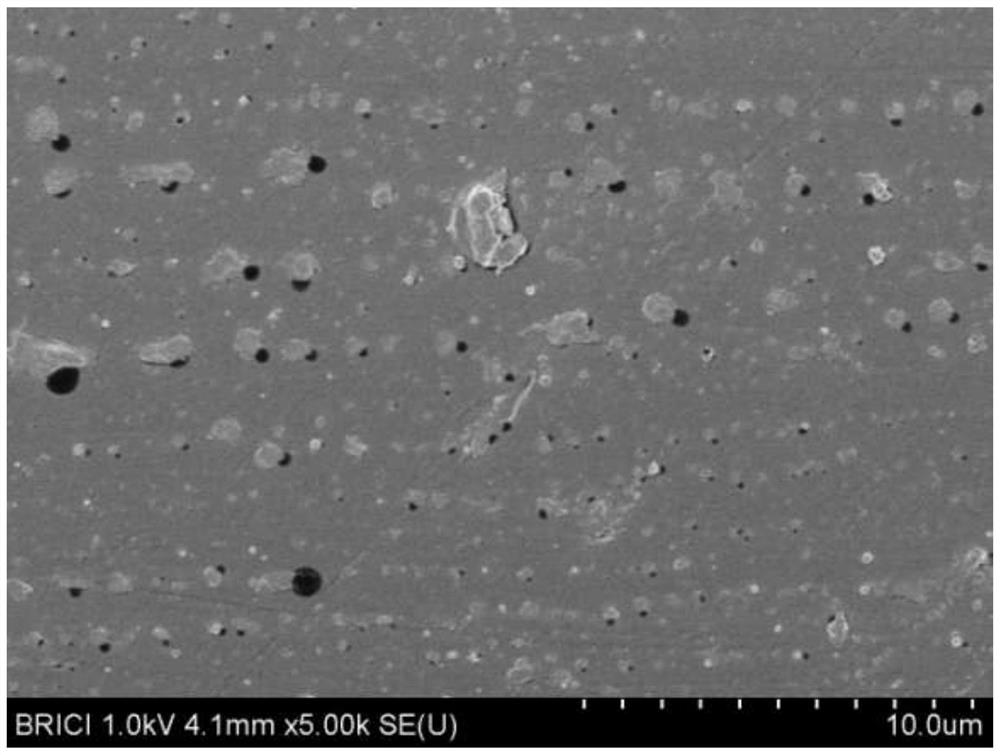

[0050] The preparation method of the alternating copolymer of maleic anhydride and styrene comprises the following steps: under the condition of nitrogen protection, monomer maleic anhydride and azobisisobutyronitrile (AIBN) initiator are joined in the isoamyl acetate medium After fully dissolving, add styrene to dissolve in the system, and react at 70°C for 8 hours to obtain a dispersion system of alternating copolymer of maleic anhydride and styrene, then centrifuge and vacuum dry to obtain maleic anhydride and styrene The white solid of the alternating copolymer (being microspheroidal, average particle diameter 400nm; The molar content of maleic anhydride is 30%), standby. Wherein, the mass percent concentration of reactants in the dispersion system is 10%, and the amount of AIBN initiator is 1% of the mass of maleic anhydride.

[0051] The preparation method of the alternating copolymer of maleic anhydride and α-methylstyrene comprises the following steps: under the condit...

Embodiment 1

[0053] Get 1000g copolymerized polypropylene powder (M60ET, Zhenhai refining and chemical production, ethylene content 1%), add 0.5g antioxidant 1010 (BASF), 0.5g antioxidant 168 (Basf), 0.5g calcium stearate Cast ( Sinopharm Group Chemical Reagent Co., Ltd.), the alternating copolymer (average particle diameter 400nm, maleic anhydride molar content 30%) of 1g maleic anhydride and styrene, carry out initial mixing, then in twin-screw extruder, screw speed setting Set at 200r / min, set the processing temperature at 175°C, extrude and granulate, and then prepare samples by injection for performance testing.

Embodiment 2

[0055] Get 1000g polypropylene powder (M60ET, produced by Zhenhai Refinery, ethylene content 1%), add 0.5g antioxidant 1010 (BASF), 0.5g antioxidant 168 (Basf), 0.5g calcium stearate Cast (Chinese medicine Group Chemical Reagent Co., Ltd.), 1g of alternating copolymers of maleic anhydride and styrene were initially mixed, and then in a twin-screw extruder, the screw speed was set at 200r / min, and the processing temperature was set at 175°C. After granulation, samples are prepared by injection for performance testing. The UV treatment time is 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com