Composite film with titanium dioxide layer and gold nanoparticles on surface and preparation method and application of composite film

A technology of nano-gold particles and titanium dioxide, which is applied in the field of membrane separation, can solve the problems of easy peeling off of the antibacterial layer, long time required for antibacterial, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

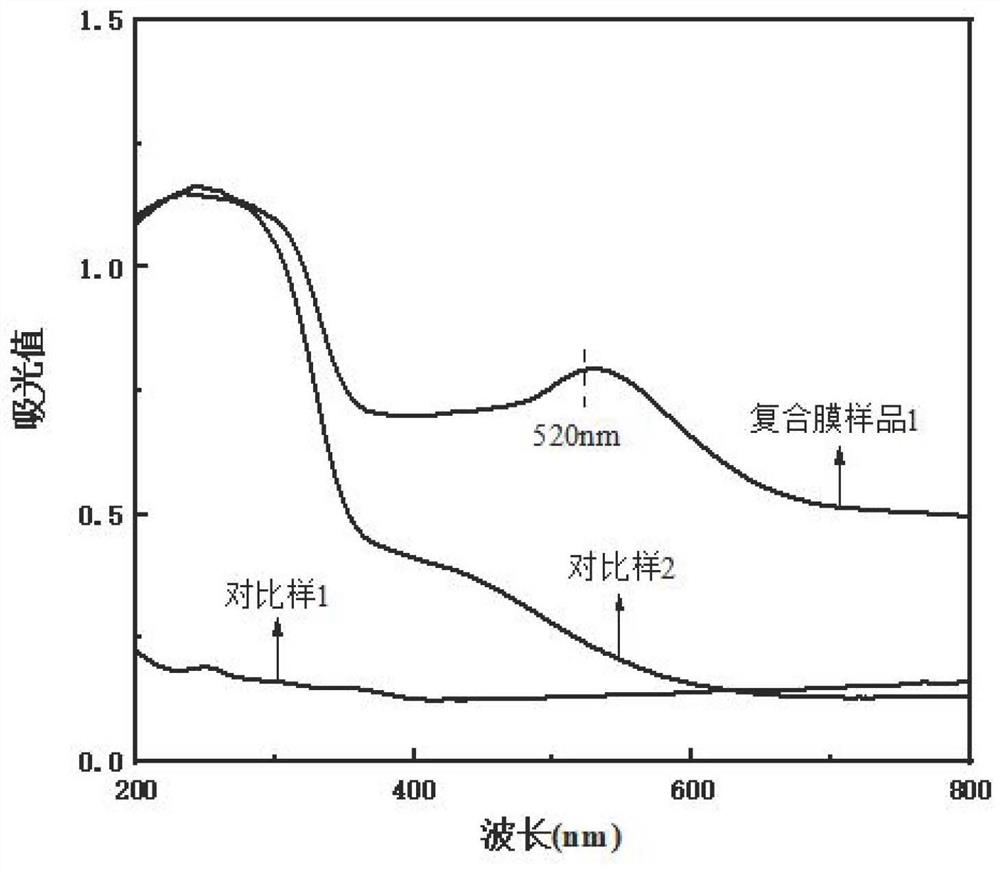

[0046] This example is the preparation of composite membrane sample 1.

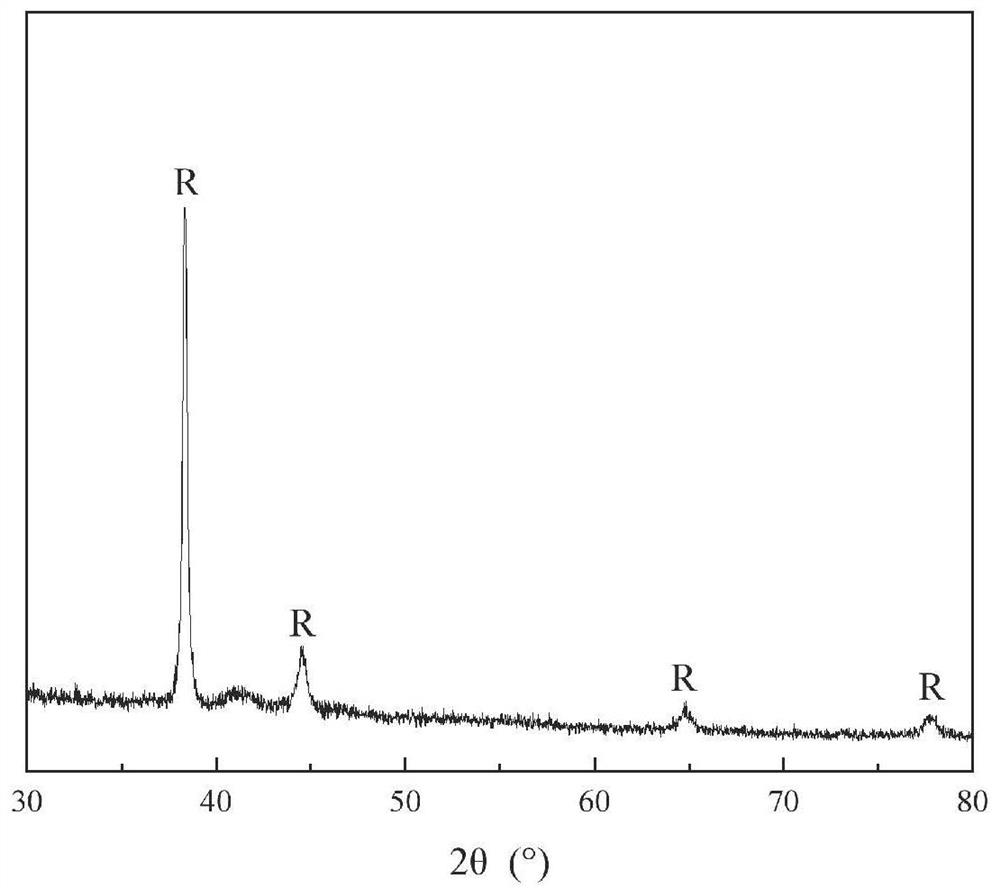

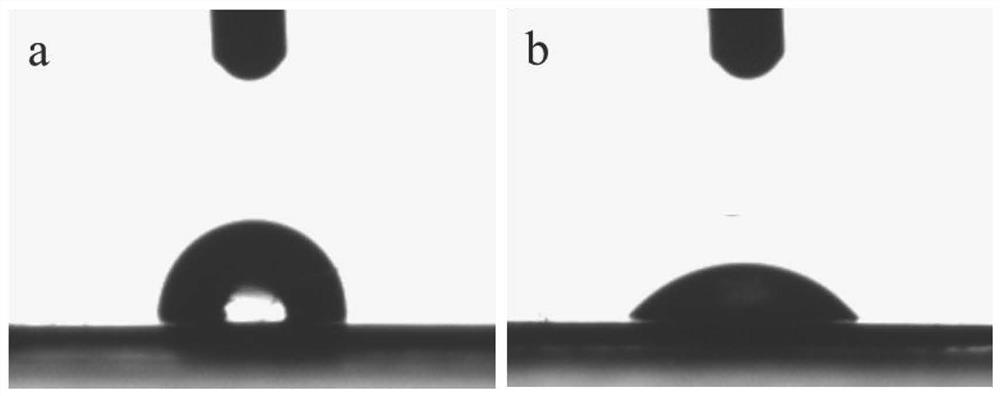

[0047] (1) Set the area to 0.05cm 2 The PVDF base film pretreatment method is: rinse with water and isoglycol in sequence and then dry. (2) Put the base film treated in step (1) into the atomic layer deposition reaction device, vacuumize, control the pressure to 50Pa, add titanium precursor to deposit layer by layer, the number of layers is 200 layers, and the temperature is controlled at 100°C. (3) Place the PVDF base film with a titanium dioxide-modified layer on the surface in a mixed solution containing methanol and chloroauric acid, and place it under a high-pressure xenon lamp (PLS-SEX300UV, 300W, Beijing Bofeilai Technology Co., Ltd.) for 30 minutes, After the light deposition, the obtained composite film was dried in a vacuum oven at 60° C. to obtain Comparative Sample 3. Wherein the mixed solution consumption is 5mL, the gold chlorate concentration in the solution is 400mg / L, and methanol accou...

Embodiment 2

[0052] This example is the preparation of composite membrane sample 2.

[0053] (1) Set the area to 0.05cm 2 The PVDF base film pretreatment method is: rinse with water and isoglycol in sequence and then dry. (2) Put the base film treated in step (1) into the atomic layer deposition reaction device, vacuumize, control the pressure to 50Pa, add titanium precursor to deposit layer by layer, the number of layers is 200 layers, and the temperature is controlled at 100°C. (3) Place the PVDF base film with a titanium dioxide-modified layer on the surface in a mixed solution containing methanol and chloroauric acid, and place it under a high-pressure xenon lamp (PLS-SEX300UV, 300W, Beijing Bofeilai Technology Co., Ltd.) for 30 minutes, After the photo-deposition, the obtained composite film was dried in a vacuum oven at 60° C. to obtain Comparative Sample 3. The amount of the mixed solution is 20 μL, the concentration of gold chlorate in the solution is 1000 mg / L, and methanol acco...

Embodiment 3

[0057] In this embodiment, the antibacterial properties of the comparative sample 1, the comparative sample 2, the composite membrane sample 1, and the composite membrane sample 2 were detected by the plate counting method: Escherichia coli was used as the strain for the test. The membrane samples to be tested were exposed to Escherichia coli bacterial suspension (10 8 cfu / mL) 3h. After discarding the bacterial suspension, use excess saline solution to rinse unattached cells from the membrane. The membrane to be tested was then transferred into 5 mL of saline solution and sonicated for 5 min in an ultrasonic bath (26W L-1, FS60 ultrasonic cleaner) to detach the bacteria from the membrane surface. After removing the bacteria from the membrane surface, the supernatant was diluted 10-fold, 100-fold and 1000-fold, then immediately cultured on LB agar medium and incubated overnight at 37°C for cfu counting. Taking the cfu of PVDF base film comparison sample 1 as a reference, calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com