Composite slurry for doping in semiconductor industry and curing film-forming processing method

A composite slurry and semiconductor technology, applied in semiconductor/solid-state device manufacturing, heating water/sewage treatment, electrical components, etc., can solve the problems of economy, environmental loss, cumbersome process, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0041] Weigh 30kg of rubber material (natural rubber, polyisoprene rubber or hydroxyl-terminated polybutadiene-styrene rubber) as the main body,

[0042] Take by weighing 15kg polyethylene glycol as dispersant;

[0043] Weigh 35kg of water and ethanol as the dispersion medium, and the ratio of water and ethanol is 1:2;

[0044] Take by weighing 30kg calcium carbonate as solid filler,

[0045] Take by weighing 15kg borax,

[0046] Stir the above materials evenly to form a viscous fluid.

preparation Embodiment 2

[0048] Weigh 40kg of rubber material (hydroxymethyl cellulose ether, ethyl cellulose or soluble starch) as the main body,

[0049] Take by weighing 9kg methyl amyl alcohol as dispersant;

[0050] Take by weighing 25kg toluene as dispersion medium;

[0051] Take by weighing 25kg titanium dioxide as solid filler,

[0052] Take by weighing 10kg trimethyl borate,

[0053] Stir the above materials evenly to form a viscous fluid.

preparation Embodiment 3

[0055] Weigh 50kg of rubber material (polyvinyl alcohol, polyvinyl butyral, polyvinyl formal or thermoplastic linear polyurethane (TPU)) as the main body,

[0056] Take by weighing 3kg fatty acid polyethylene glycol ester as dispersant;

[0057] Weigh 15kg of trichloroethylene and diethylene glycol as the dispersion medium, and the ratio of trichloroethylene and diethylene glycol is 1:1;

[0058] Weigh 20kg diatomaceous earth as solid filler,

[0059] Weigh 5kg phosphorus element,

[0060] Stir the above materials evenly to form a viscous fluid.

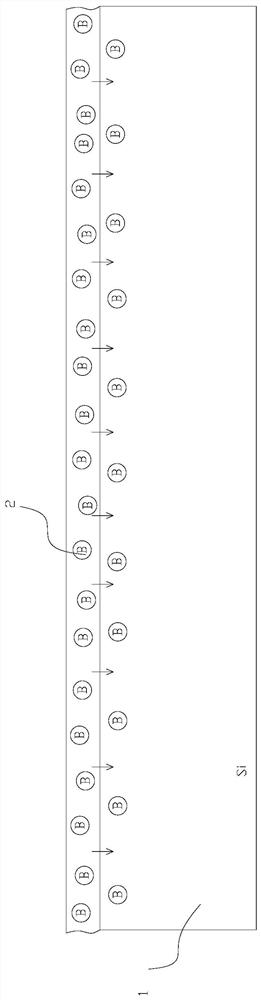

[0061] The invention relates to a solidification and film-forming processing method of a composite slurry for doping in the semiconductor industry. The composite slurry for doping is processed by wet papermaking equipment, and the doped The composite slurry is used for water washing, and the water washing adopts deionized water or ultrapure water.

[0062] During specific production, the above-mentioned slurry is immersed in pure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com