Synthetic method of nanofiber membrane-shaped efficient water body solid-phase denitrification carbon source

A nanofiber membrane, nitrocarbon source technology, applied in chemical instruments and methods, fiber treatment, water pollutants, etc., can solve the problems of limited application of efficiency, precipitation of other pollutants, insufficient reaction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

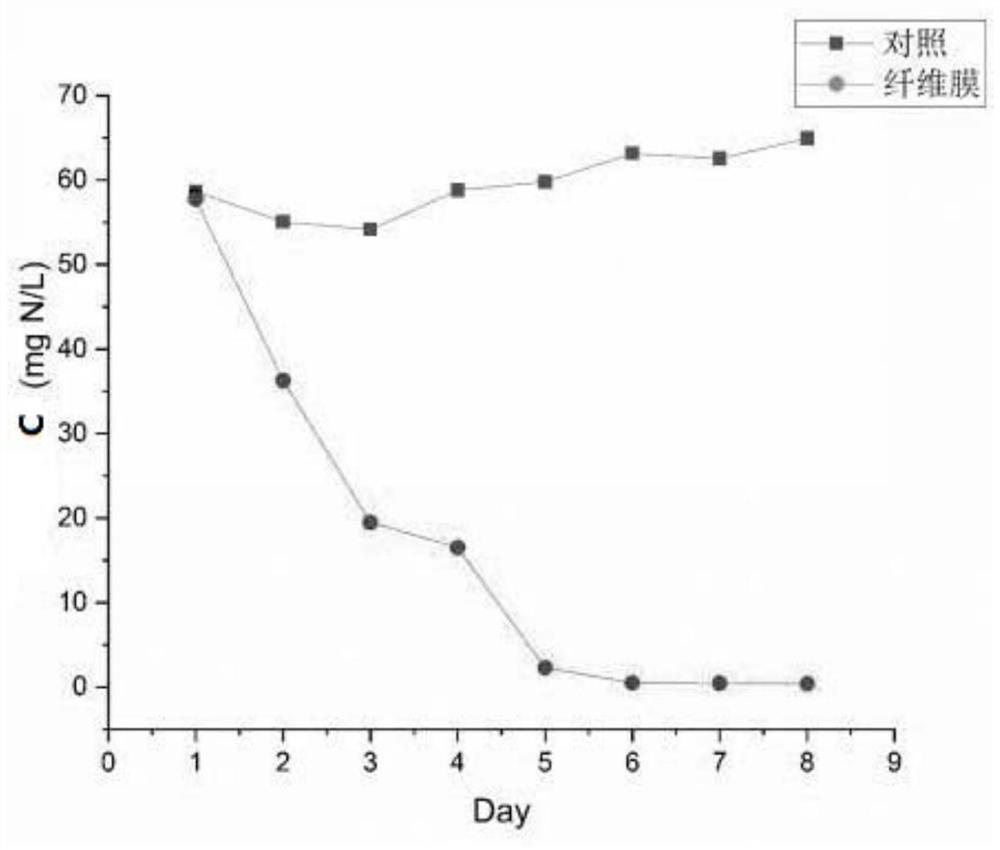

[0020] Example 1, PHB (polyhydroxybutyrate), PHBV (polyhydroxyvalerate) and PLA (polylactic acid) were mixed at 1:1:1 to form a solid phase mixture, and DMF (dimethylformamide) After mixing with chloroform at 1:9 to form a liquid phase mixture, the solid phase mixture was blended into the liquid phase mixture at 35°C to obtain 8wt.% PHB (polyhydroxybutyrate) / PHBV (polyhydroxyvalerate) / PLA (polylactic acid) content of the polymer solution; above-mentioned polymer solution is carried out electrospinning, and regulating spinning voltage is 25kv, and receiving distance is 25cm, and ambient humidity is 35% relative humidity, and temperature is 30 ℃, on release paper Collect the obtained electrospun nanofiber membrane; place the electrospun nanofiber membrane in a vacuum oven at 60°C for 2 hours to evaporate the liquid solvent, then wash it with deionized water and bake it in an oven at 80°C for 2 hours to dry , to obtain a nanofiber film-like high-efficiency solid phase nitrificati...

Embodiment 2

[0023] Example 2, PBS (polybutylene succinate), PHA (polyhydroxyalkanoate) and PLA (polylactic acid) are mixed at 1:5:1 to form a solid phase mixture, and DMF (dimethyl formamide) mixed with chloroform 2:8 to form a liquid phase mixture, and the solid phase mixture was blended into the liquid phase mixture at 40°C to obtain 7wt.% PHB (polyhydroxybutyrate) / PHBV (polyhydroxyvalerate ) / PLA (polylactic acid) content of the polymer solution; the above-mentioned polymer solution is electrospun, the adjustment spinning voltage is 20kv, the receiving distance is 25cm, the ambient humidity is 30% relative humidity, and the temperature is 35°C. The electrospun nanofiber membrane collected on the type paper; place the electrospun nanofiber membrane in a vacuum oven at 60°C for 2 hours to evaporate the liquid solvent, then wash it with deionized water and bake it in an oven at 80°C for 2 hours to drying to obtain a nanofiber film-like high-efficiency solid phase nitrification carbon sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com