A method for pretreatment of biomass cascade deashing

A biomass and pretreatment technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as mass loss, high cost of elution solvents, and biomass hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 (experimental group):

[0023] A method for pretreatment of biomass cascade deliming provided in this embodiment comprises the following steps:

[0024] (1) Soak the rice husk powder in water according to the solid-liquid ratio of 1:30, stir at 50°C for 4 hours, filter, and dry at 105°C for 24 hours to obtain stepwise water-washed biomass powder (C-H 2 O-RS).

[0025] (2) The water-washed biomass powder was soaked in 0.1mol / L acetic acid solution, stirred at 50°C for 4h, filtered, and dried at 105°C for 24h to obtain stepwise acetic acid-washed biomass powder (C-HAC-RS).

[0026] (3) Immerse the acetic acid-washed biomass powder in 0.1mol / L hydrochloric acid solution, stir at 50°C for 4h, and then filter to obtain the cascade hydrochloric acid-washed biomass powder, and finally obtain the cascade pretreated delimed biomass (C -RS).

[0027] (4) Using nitric acid and hydrogen peroxide as digestion agents, the samples were digested and kept at 220°C, and t...

Embodiment 2

[0028] Embodiment 2 (control group):

[0029] A method for pretreatment of biomass cascade deliming provided in this embodiment comprises the following steps:

[0030] (1) Soak the rice husk powder in water, 1.0mol / L acetic acid solution and 1.0mol / L hydrochloric acid solution according to the solid-liquid ratio of 1:30, stir at 50°C for 4h, filter, and dry at 105°C 24h to obtain the hydrated biomass mixture, the acetic acid biomass mixture and the hydrochloric acid biomass mixture respectively, and finally obtain the water-washed biomass (H 2 O-RS-1), acetic acid delimed biomass (HAC-RS-1) and hydrochloric acid delimed biomass (HCl-RS-1).

[0031] (2) Using nitric acid and hydrogen peroxide as digestion agents, the samples were digested and kept at 220°C, and the ash content in the obtained digestion solution was determined by ICP-OES.

Embodiment 3

[0032] Embodiment 3 (control group):

[0033] A method for pretreatment of biomass cascade deliming provided in this embodiment comprises the following steps:

[0034] (1) Soak rice husk powder in water, 0.1mol / L acetic acid solution and 0.1mol / L hydrochloric acid solution according to the ratio of solid to liquid: 1:30, stir at 50°C for 4h, filter, and dry at 105°C 24h to obtain the hydrated biomass mixture, the acetic acid biomass mixture and the hydrochloric acid biomass mixture respectively, and finally obtain the water-washed biomass (H 2 O-RS-0.1), acetic acid delimed biomass (HAC-RS-0.1) and hydrochloric acid delimed biomass (HCl-RS-0.1).

[0035] (2) Using nitric acid and hydrogen peroxide as digestion agents, the samples were digested and kept at 220°C, and the ash content in the obtained digestion solution was determined by ICP-OES.

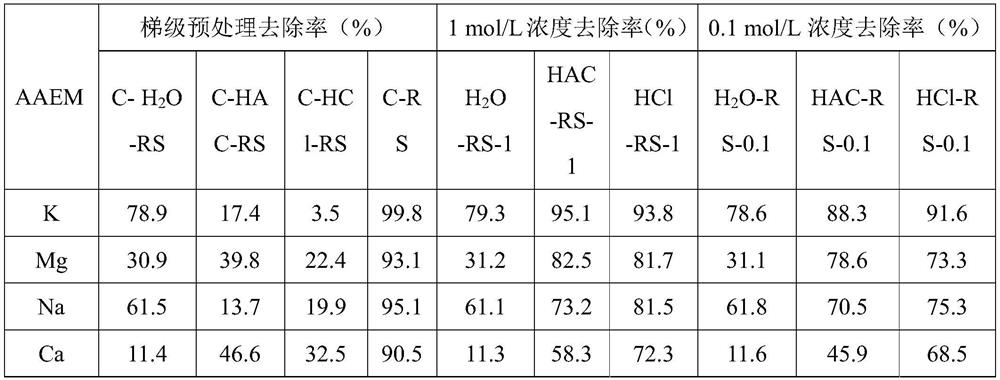

[0036] Table 1: Effects of different deliming agents, different concentrations and different removal methods on the content and remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com