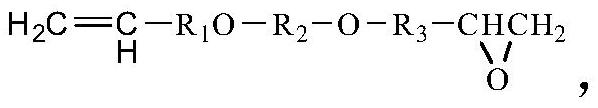

Epoxy-terminated vinyl ether monomer as well as preparation method and application thereof

A technology of epoxy-terminated vinyl ether and hydroxy-terminated alkenyl ether, which is applied in the field of epoxy-terminated vinyl ether monomer and its preparation, can solve the problems of environmental protection, slow reaction rate, brittle dielectric constant of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

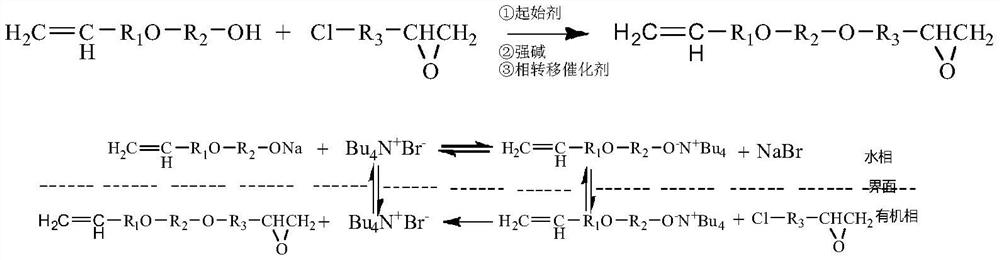

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Synthesis of 2-vinyloxyethyl glycidyl ether and its application in polysulfide rubber

[0033] Take 176g of ethylene glycol monovinyl ether, 88g of sodium hydroxide, and 370g of epichlorohydrin, feed them into a 2L reaction kettle, add 1.5g of tetrabutylammonium bromide, 0.5g of hydroquinone, and 0.1g of hydrogenated Sodium, quickly closed reactor. Start stirring, use the heat of reaction to heat up to 55°C, then turn on the heating device to quickly raise the temperature to 105°C, keep the total pressure in the kettle constant (the pressure after constant is 0.6kPa) and keep it warm for 3 hours, then cool down to 50°C and keep it warm for 3 hours to discharge. Distillation under reduced pressure can obtain 260g 2-vinyloxyethyl glycidyl ether product, its structure is 99.0% purity.

[0034]Dithiol-terminated liquid polysulfide rubber (relative molecular mass 1000, mercapto group content is 6.6%) 500g and 40g 2-vinyloxyethyl glycidyl ether are mixed at room ...

Embodiment 2

[0036] Example 2 Synthesis of 2-vinyloxybutyl glycidyl ether and its application on polysiloxane

[0037] Take hydroxybutyl vinyl ether (H 2 C=CHO(CH 2 ) 4 OH) 348g, potassium hydroxide 168g, epichlorohydrin 416g, feed in 3L reactor, add 5g benzyltriethylammonium chloride successively, 1g polyethylene glycol (4000), 1g hydroquinone, 0.5g sodium ethoxide, quickly close the reaction kettle. Turn on the stirring, use the heat of reaction to heat to 65°C, then turn on the heating to quickly raise the temperature to 115°C, keep the total pressure in the kettle constant (the pressure after constant is 1.4kPa) and keep it warm for 6 hours, then cool it down to 50°C and keep it warm for 3 hours to discharge. Crude distillation recovers epichlorohydrin, vacuum distillation obtains hydroxybutyl vinyl ether and 2-vinyloxybutyl glycidyl ether mixture, and rectification can be separated to obtain 400g 2-vinyloxybutyl glycidyl ether product, 98.5% purity.

[0038] Hydrogen-terminated s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com