In-situ regulated and controlled water-based super-amphiphobic coating layers and preparation method thereof

A super-amphiphobic, coating technology, used in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of complex preparation and hinder the flipping of surface active molecular chains, and achieve easy availability of raw materials and low cost. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

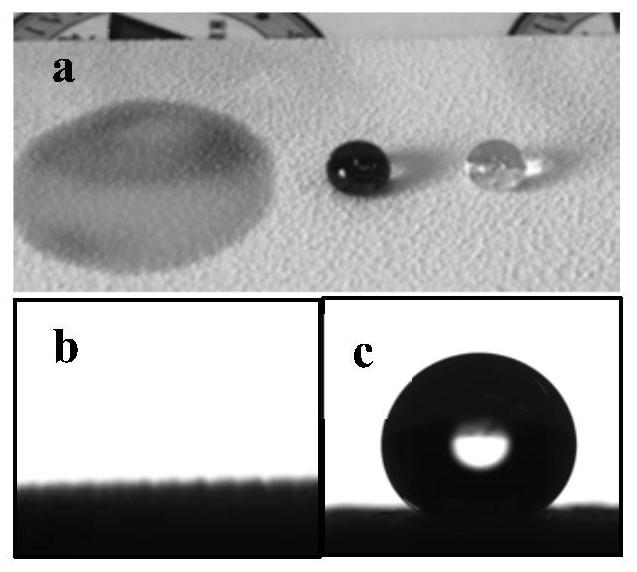

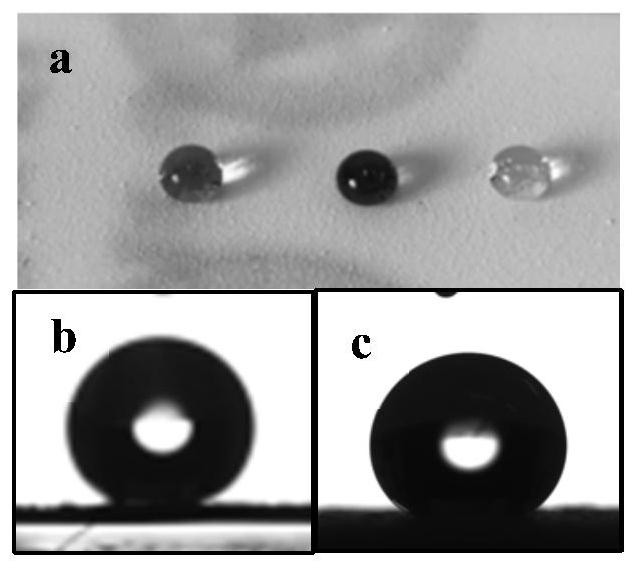

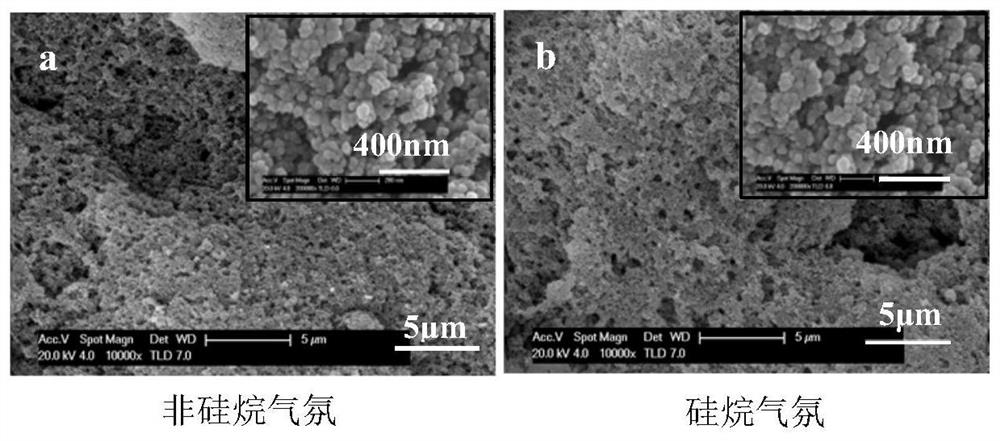

[0029] Disperse 15g of carboxylic acid-based fluorosurfactant Capstone FS-61 and 10g of silica particles with a maximum dimension of 7-40nm in 300g of water, stir mechanically for 30min until uniform, add 15g of water-based polyurethane film-forming agent, add 1.65g of disperse Sodium dodecylbenzene sulfonate and 1.65g thickener sodium polyacrylate were ultrasonically dispersed for 10 minutes, dispersed uniformly and then sprayed on the surface of the substrate to obtain the initial surface ( figure 1 : a). The initial surface is superhydrophilic and superoleophobic, and the static contact angle of water droplets is 0°( figure 1 : b), the static contact angle of the oil droplet is 152.7° ( figure 1 : c), the rolling angle is 8°; then it is 0.4mg / m at 80℃ 3 After being regulated in the atmosphere of heptadecafluorodecyltriethoxysilane for 15 minutes, the fluoroalkyl group is oriented outward, and a superamphiphobic material is obtained, and the coating is superamphiphobic ( ...

Embodiment 2

[0031]Disperse 10g of phosphoric acid-based fluorosurfactant Zonyl 9361 and 10g of sludge powder particles with a maximum dimension of 10-60μm in 300g of water, stir mechanically for 30min until uniform, add 15g of water-based acrylic film-forming agent, and add 1g of dispersant polysorbate (Tween) and 1.5g thickener polyvinylpyrrolidone, ultrasonically dispersed for 10min, evenly dispersed, brushed on the surface of the substrate, and dried naturally in the air for 2h to obtain the initial surface. The initial surface is superhydrophilic and superoleophobic, the static contact angle of water droplets is 0°, the static contact angle of oil droplets is 152.7°, and the rolling angle is 8°; 3 After being regulated in the ethanol atmosphere for 15 minutes, the halothane group is oriented outward, and the superamphiphobic material is obtained. The coating is superamphiphobic. The static contact angle of water droplets is 159°, the rolling angle is 3°, and the static contact angle of...

Embodiment 3

[0033] 150g of carboxylic acid-based fluorosurfactant FS-61 and 90g of TiO2 with the largest dimension of 200nm 2 Disperse the particles in 3000g water, stir mechanically for 60min until uniform, add 150g water-based polybutadiene resin film-forming agent, add 10g dispersant fatty acid sorbitan (Span) and 15g thickener polyacrylate copolymer emulsion, ultrasonically disperse for 10min, Dip coating on the surface of the substrate after uniform dispersion to obtain the initial surface, the initial surface is super-hydrophilic and super-oleophobic, the static contact angle of water droplets is 0°, the static contact angle of oil droplets is 150.7°, and the rolling angle is 10°; At ℃, 0.1mg / m 3 After being regulated in the acetone atmosphere for 7 minutes, the halothane group is oriented outward, and the superamphiphobic material is obtained. The coating is superamphiphobic. The static contact angle of water droplets is 157°, the rolling angle is 7°, and the static contact angle o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com