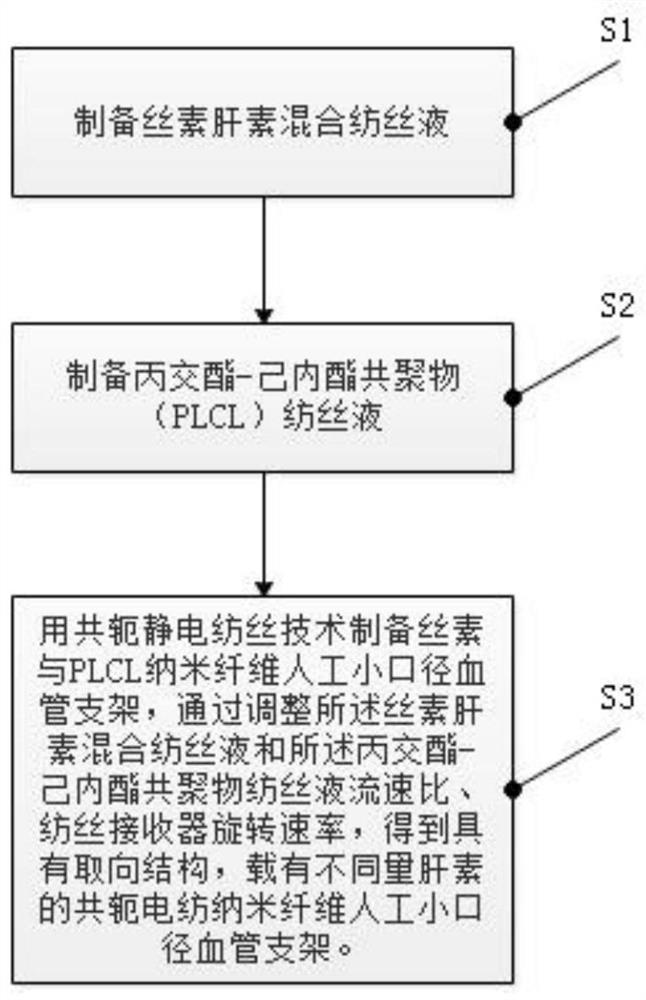

Preparation method of conjugate electrospinning nanofiber artificial small-caliber intravascular stent and product

A technology of electrospinning nanofibers and vascular stents, which is used in textiles and papermaking, food packaging, pharmaceutical packaging, etc. Stenosis and other problems, to achieve the effect of simple and effective patency rate, good biocompatibility, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) To prepare a silk fibroin solution, dissolve the silk fibroin in purified water at room temperature with a silk fibroin concentration of 10%, and stir for 1 hour to ensure that the silk fibroin is fully dissolved.

[0021] (2) Add PEO to the silk fibroin solution, the concentration is 1%, and the ratio of PEO to silk fibroin is 1:10

[0022] (3) Prepare silk fibroin and heparin mixed spinning solution, dissolve heparin in the prepared PEO-silk fibroin solution, the heparin concentration is 1%.

[0023] (4) Prepare PLCL spinning solution, dissolve lactide-caprolactone copolymer PLCL in hexafluoroisopropanol HFIP at a concentration of 8%.

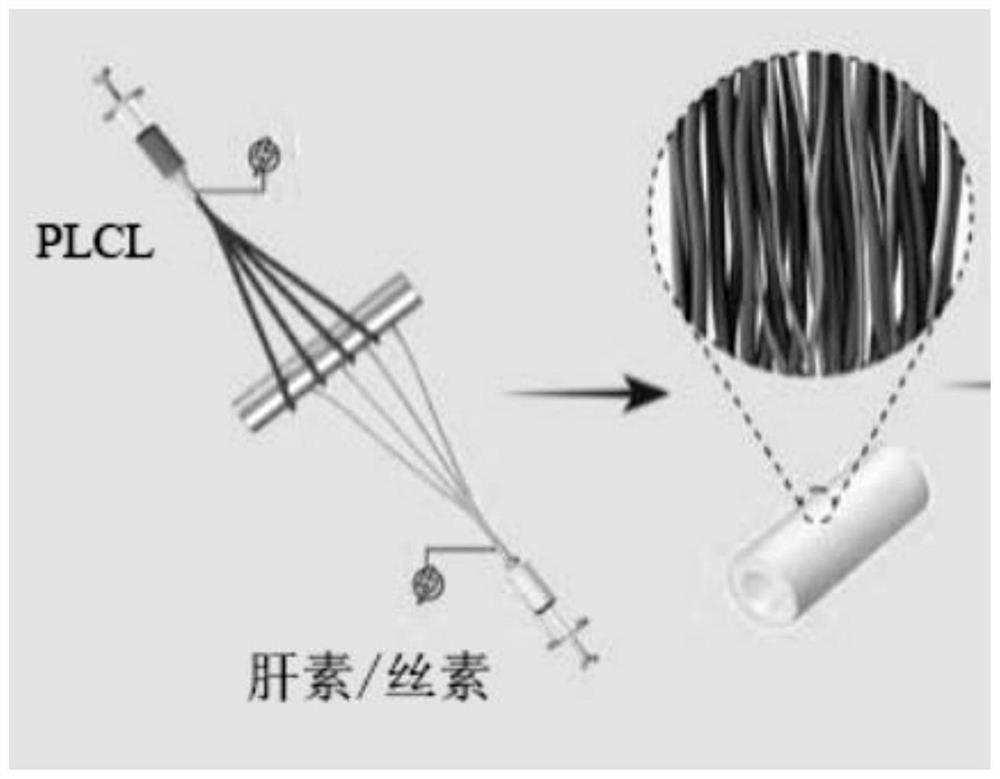

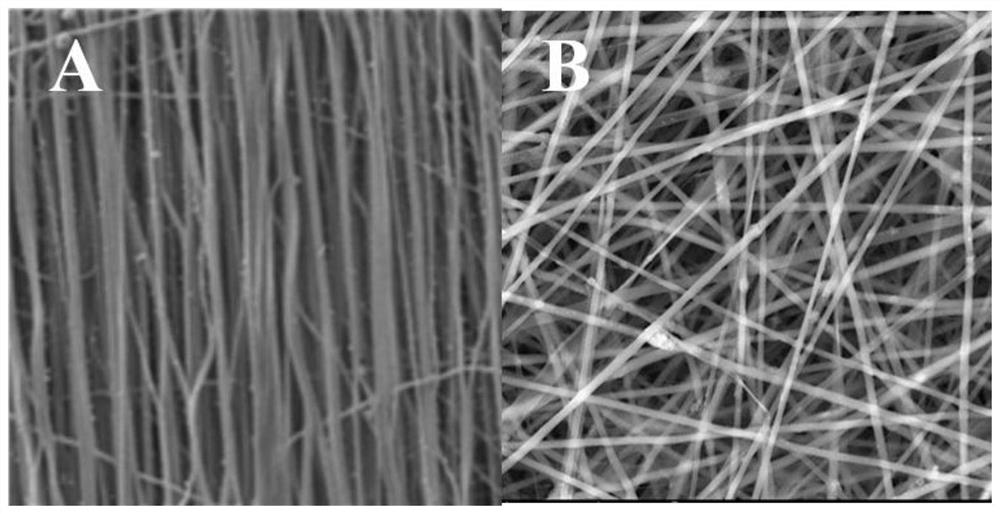

[0024] (5) Prepare silk fibroin and PLCL nanofiber artificial small-caliber vascular stent by conjugate electrospinning technology, the voltage of PLCL nanofiber spinning is 10kV, the solution flow rate is 1.0ML / h, and the voltage of silk fibroin nanofiber spinning is 10kV, the solution flow rate is 0.8ML / h.

[0025] (6) The rece...

Embodiment 2

[0028] (1) To prepare a silk fibroin solution, dissolve the silk fibroin in purified water at room temperature with a silk fibroin concentration of 20%, and stir for 1 hour to ensure that the silk fibroin is fully dissolved.

[0029] (2) Add PEO to the silk fibroin solution, the concentration is 2%, and the ratio of PEO to silk fibroin is 1:10

[0030] (3) Prepare silk fibroin and heparin mixed spinning solution, dissolve heparin in the prepared PEO-silk fibroin solution, the heparin concentration is 3%.

[0031] (4) Prepare PLCL spinning solution, dissolve lactide-caprolactone copolymer PLCL in hexafluoroisopropanol HFIP at a concentration of 10%.

[0032] (5) Prepare silk fibroin and PLCL nanofiber artificial small-caliber vascular stent by conjugate electrospinning technology, the voltage of PLCL nanofiber spinning is 15kV, the solution flow rate is 1.0ML / h, and the voltage of silk fibroin nanofiber spinning is 15kV, the solution flow rate is 1.2ML / h.

[0033] (6) The rot...

Embodiment 3

[0036] (1) To prepare a silk fibroin solution, dissolve the silk fibroin in purified water at room temperature with a silk fibroin concentration of 15%, and stir for 1 hour to ensure that the silk fibroin is fully dissolved.

[0037] (2) Add PEO to the silk fibroin solution, the concentration is 1.5%, and the ratio of PEO to silk fibroin is 1:10

[0038] (3) Prepare silk fibroin and heparin mixed spinning solution, dissolve heparin in the prepared PEO-silk fibroin solution, the heparin concentration is 3%.

[0039] (4) Prepare PLCL spinning solution, dissolve lactide-caprolactone copolymer PLCL in hexafluoroisopropanol HFIP at a concentration of 9%.

[0040] (5) Prepare silk fibroin and PLCL nanofiber artificial small-diameter vascular stent by conjugate electrospinning technology, the voltage of PLCL nanofiber spinning is 12kV, the solution flow rate is 1.0ML / h, and the voltage of silk fibroin nanofiber spinning is 12kV, the solution flow rate is 1.0ML / h.

[0041] (6) The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com