Mesoporous nanorod-like catalyst as well as preparation method and application thereof

A nano-rod-shaped, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the waste of resources and energy, increase processing energy consumption, utilization rate Low and other problems, to achieve the effect of improving efficiency, saving processing energy costs, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

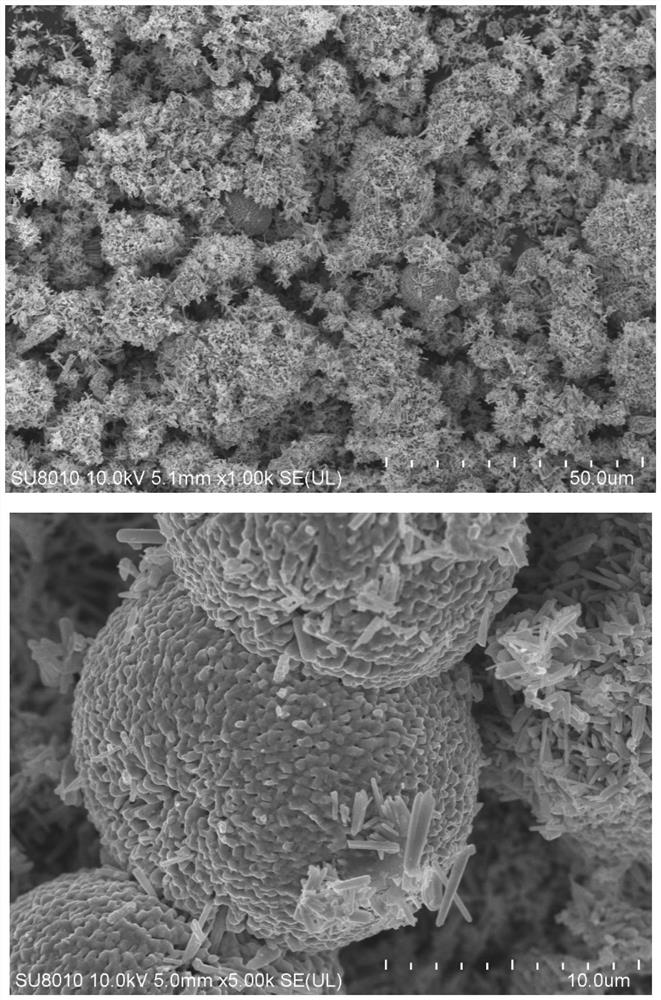

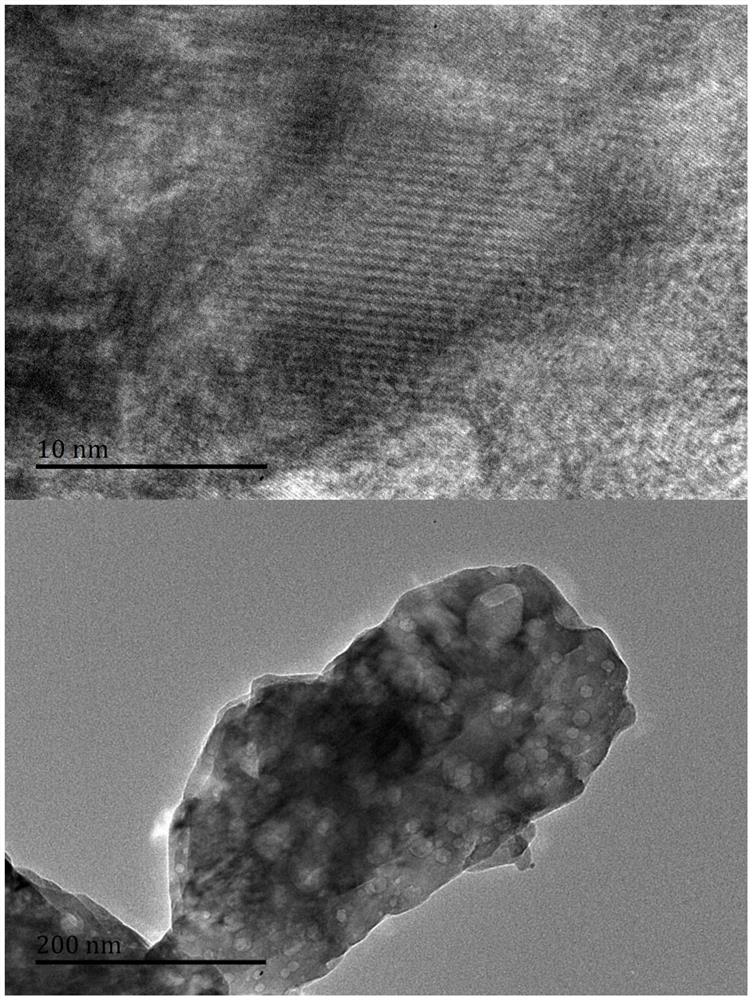

[0045] This implementation is an embodiment of a method for preparing a mesoporous nanorod catalyst of the present invention, which includes the following steps:

[0046] (1) 2.975g of Zn(NO 3 ) 2 ·6H 2 O and 2.416g of Cu(NO 3 ) 2 ·3H 2 O was added to 100mL deionized water, and stirred at 35°C for 30 minutes to obtain a solution;

[0047] (2) Add 50 mL of 0.4 mol / L sodium hydroxide solution to the solution obtained in step (1), stir and mix well, then adjust the pH value of the system to 11 with ammonia water to obtain a mixed system A;

[0048] (3) Put the mixed system A obtained in step (2) in a closed reaction vessel, and carry out a hydrothermal reaction at a temperature of 150° C., and the hydrothermal reaction time is 8 hours, to obtain a mixed system B;

[0049] (4) After the solid-liquid separation of the mixed system B, the solid was collected, washed with deionized water, dried, and ground in sequence to obtain solid C;

[0050] (5) Put the solid C in a tube f...

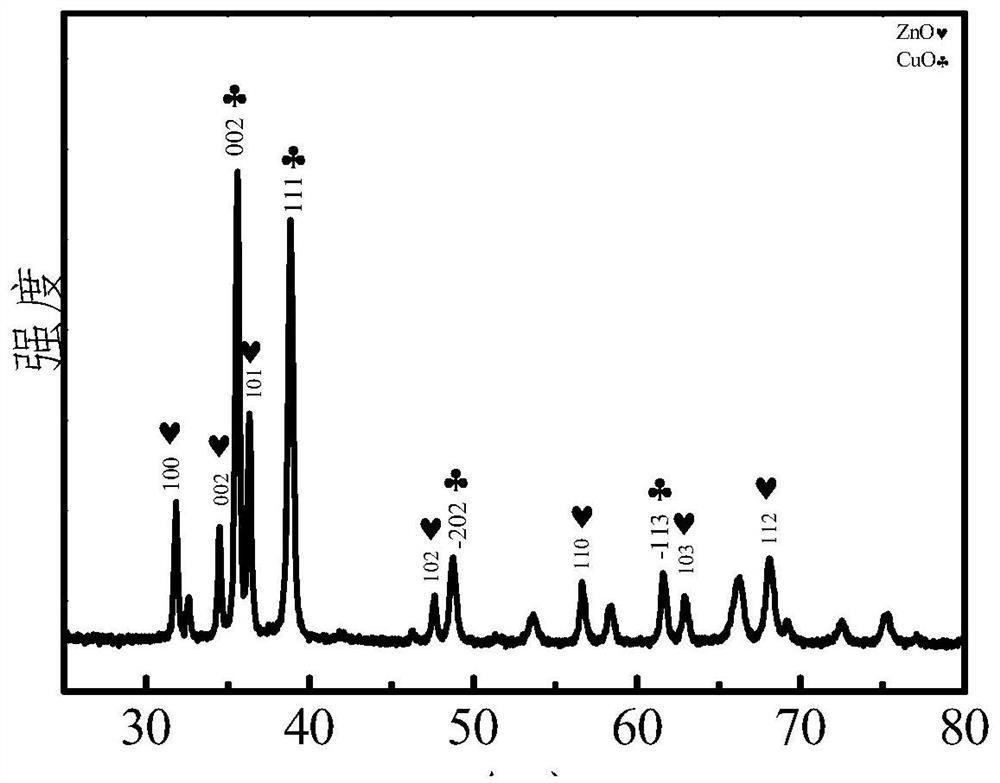

Embodiment 2

[0054] This implementation is an embodiment of a method for preparing a mesoporous nanorod catalyst of the present invention, except for the Cu(NO 3 ) 2 ·3H 2 Except that the quality of O is 1.208g, the others are the same as in Example 1, and the catalyst obtained is a copper oxide-doped zinc oxide catalyst, which is referred to as ZnCu 0.5 O catalyst.

Embodiment 3

[0056] This implementation is an embodiment of a method for preparing a mesoporous nanorod catalyst of the present invention, except for the Cu(NO 3 ) 2 ·3H 2 Except that the quality of O is 4.832g, others are the same as in Example 1, and the obtained catalyst is a copper oxide-doped zinc oxide catalyst, which is referred to as ZnCu 2 O catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com