Texturing additive capable of regulating and controlling hydrophilicity and hydrophobicity of silicon wafer and texturing method

A technology of additives and silicon wafers, which is applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems that the texturing liquid cannot be handled, and achieve the conversion of easy hydrophilicity and hydrophobicity, simple operation process, and meet the processing needs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

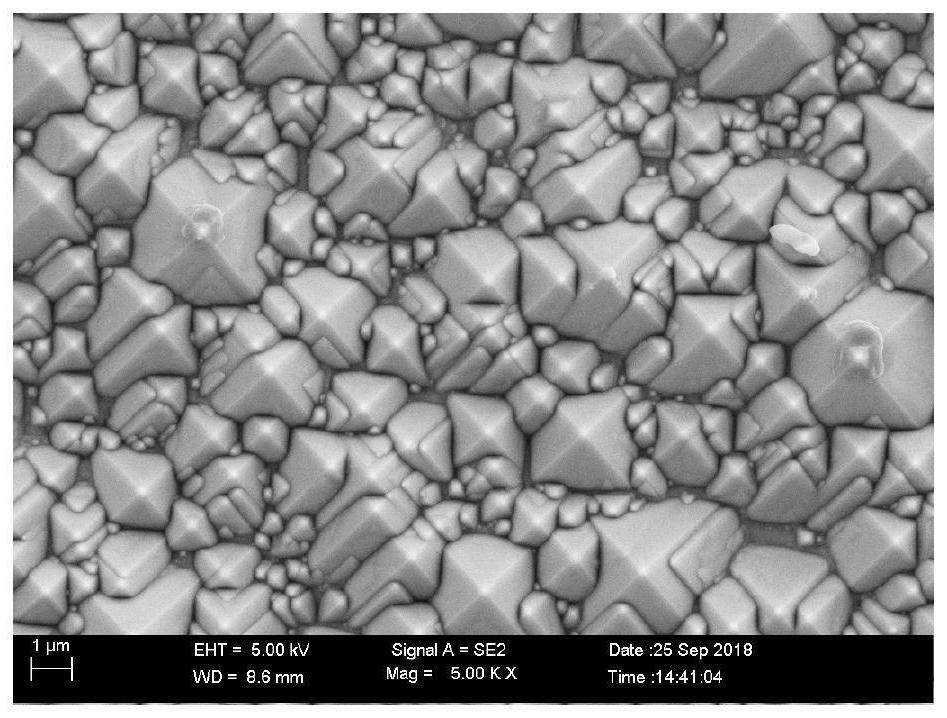

Embodiment 1

[0032] Preparation of hydrophilic texturizing additives: Weigh the following substances by weight in order for ultrasonic dissolution: 0.05% sodium lignosulfonate, 0.0001% sodium methylene bis-naphthalenesulfonate and the rest of water;

[0033] Add the above-mentioned texturizing additive into 1.8% sodium hydroxide or potassium hydroxide solution, mix evenly at a temperature of 20°C, wherein the mass ratio of the texturing additive to the alkali solution is 1:100, and obtain the texturing liquid.

[0034] The method for making texture on the surface of monocrystalline silicon comprises the following steps:

[0035] Step 1: Pre-treat the monocrystalline silicon wafer. The pretreatment process is as follows: the first step, put the monocrystalline silicon wafer in absolute ethanol for 8 minutes, and clean it with deionized water; the second step, put the monocrystalline silicon wafer Put the wafer in propanol for 8 minutes and clean it with deionized water; in the third step, p...

Embodiment 1a

[0038] In Example 1a, the surface texturing temperature of monocrystalline silicon is 80° C., the texturing time is 1200 s, and other parameters are the same as in Example 1.

Embodiment 1b

[0040] In Example 1b, the texturing temperature on the surface of the monocrystalline silicon was 83° C., the texturing time was 900 s, and other parameters were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com