Method for degrading organic pollutants based on biochar

A technology for organic pollutants and biochar, which is applied in the restoration of water pollutants and polluted soil, chemical instruments and methods, etc., can solve the problems of unsatisfactory reduction of organic pollutants, etc., and achieve non-toxic and reactive products. High, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of biochar comprises the following steps:

[0033] (1) The sawdust biomass is washed with clear water, dried and crushed for subsequent use;

[0034] (2) Heat the sawdust biomass dried in step (1) to 350°C, 500°C and 700°C in a nitrogen-filled muffle furnace respectively, at a heating rate of 5°C / min to 8°C / min, and heat for 4 hours Cool to room temperature afterward, pass through 100 mesh sieves and obtain three kinds of biochars for use;

[0035] (3) In step (2), 500°C biochar and hydrogen peroxide solution with a mass fraction of 10% were mixed and stirred for 5 hours, and the stirring speed was 100-200r / min, then washed and dried with ultrapure water, and passed through 100 Mesh sieve to obtain oxidized biochar stand-by;

[0036] (4) In step (2), 500°C biochar and potassium borohydride solution with a mass fraction of 5% were mixed and stirred for 5 hours. Mesh sieve to obtain reduced biochar for use.

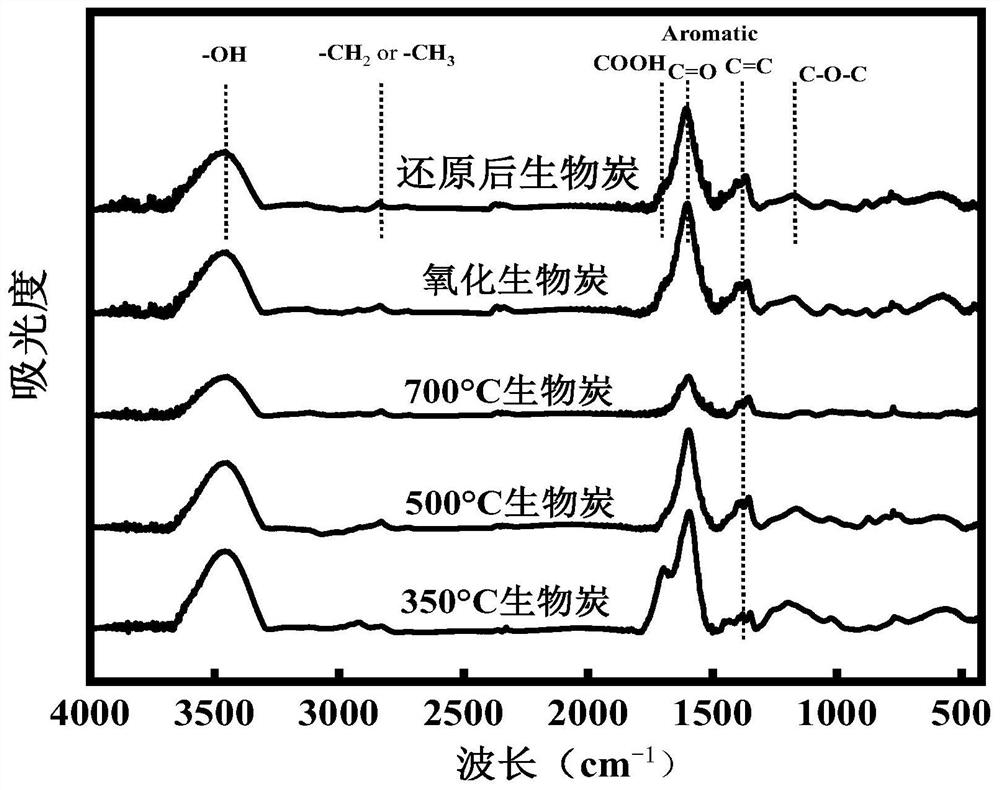

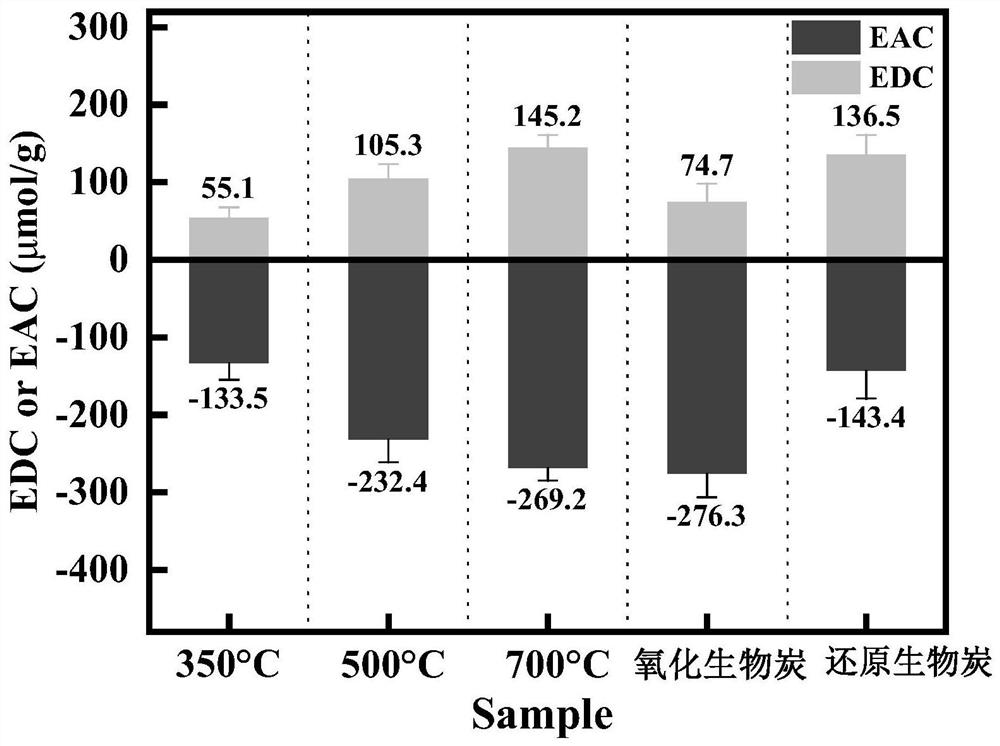

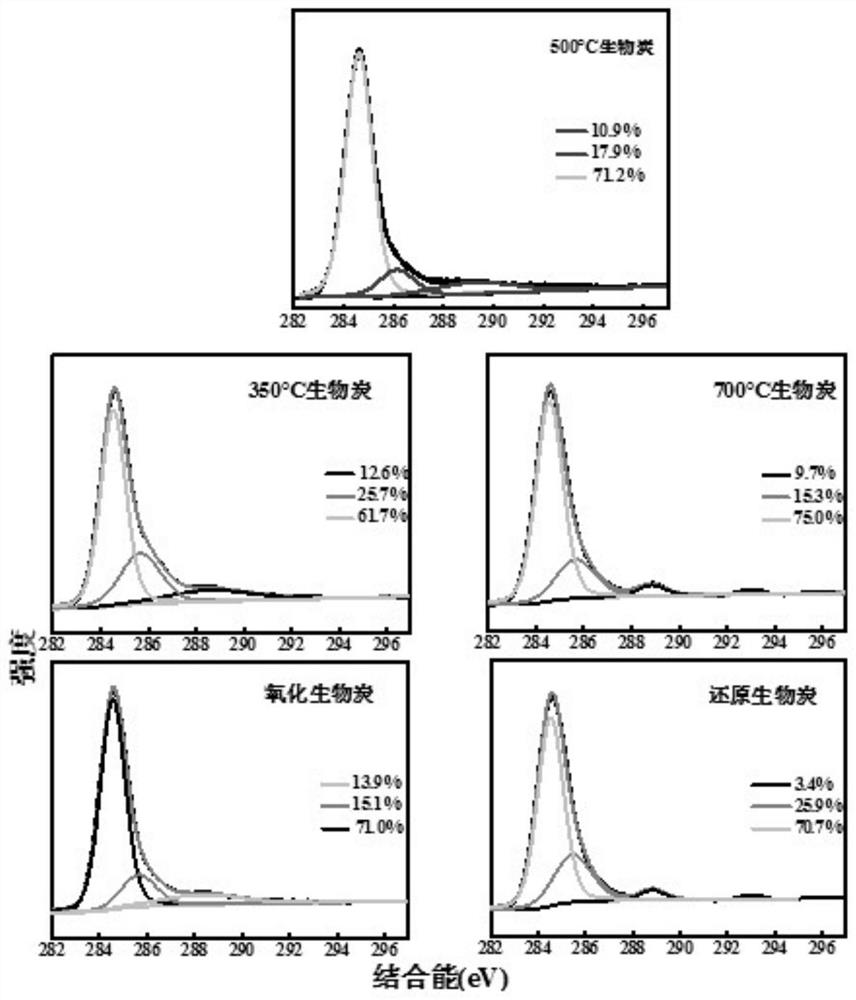

[0037] figure 1 The infrared spectr...

Embodiment 2

[0045] In order to study the influence of pH value on the reaction process, the organic pollutant 2,4-dichlorophenol was oxidatively degraded by using the 500°C biochar prepared in Example 1. The specific steps are as follows:

[0046] The initial concentration of 2,4-dichlorophenol was 50 mg / L (ppm), and the pH value was adjusted to 3, 5, 6, 7 and 9 with dilute sulfuric acid and dilute sodium hydroxide respectively. There were five groups in total, and the solution volume was 20 mL. , after adding ferric sulfate, sodium persulfate and biochar, the concentration of ferric ion is 0.2g / L, the concentration of sodium persulfate is 2.1g / L, and the dosage of biochar is 40mg. At the temperature of 298K, the rotational speed is Stirring treatment at 115rpm, oxidative degradation for 5 hours, detection at time 30min, 1h, 2h, 3h, 4h and 5h respectively.

[0047] Figure 4 is the influence curve of pH value on oxidative degradation; it can be seen from the figure that pH value has litt...

Embodiment 3

[0049] In order to study the influence of no dosage of biochar on the reaction process, the 500°C biochar prepared in Example 1 was used to conduct an oxidative degradation experiment on the organic pollutant 2,4-dichlorophenol. The specific steps are as follows:

[0050]The initial concentration of 2,4-dichlorophenol is 50mg / L (ppm), the pH value is 6 (the original solution without adding any acid and alkali), and the solution volume is 20mL. After adding ferric acetate, sodium persulfate, and biochar, The concentration of ferric ion is 0.2g / L, the concentration of sodium persulfate is 2.1g / L, and the dosage of biochar is 20mg, 30mg, 40mg and 50mg respectively. There are four groups in total. At the temperature of 298K, the rotation speed is 200r / Stirring treatment at 1 min, oxidative degradation for 5 hours, detection at time 30min, 1h, 2h, 3h, 4h and 5h respectively.

[0051] Figure 5 It is the effect curve of different doses of biochar on the removal of organic pollutan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com