Cross-linking agent, polyurethane prepolymer and one-component polyurethane adhesive

A technology of polyurethane prepolymer and crosslinking agent, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of high mechanical performance and tensile performance, and achieve high mechanical performance and huge application Excellent value and overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the polyurethane prepolymer needs only to polymerize the above-mentioned polymerizable composition. For example: take polyisocyanate, polyether polyol, polydimethylsiloxane, the crosslinking agent, and the first catalyst, and mix and react. The method of aggregation is not particularly limited. The order of adding each substance can be carried out according to conventional operations known to those skilled in the art.

[0067] In one embodiment, the temperature of the polymerization reaction is 40° C. to 80° C., and the reaction time is 1 h to 5 h. It can be understood that the way of mixing includes but not limited to stirring.

[0068] The present invention further provides a one-component polyurethane glue, the raw materials of which include: the above-mentioned polyurethane prepolymer, inorganic filler, coupling agent and second catalyst.

[0069] In one embodiment, the one-component polyurethane glue, in parts by weight, its raw materia...

Embodiment 1

[0081] Embodiment 1: the preparation of crosslinking agent

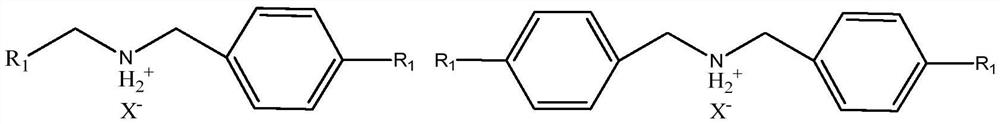

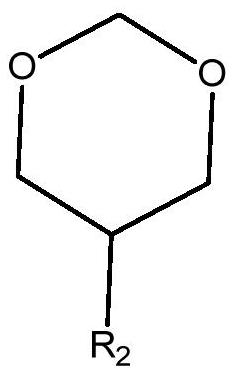

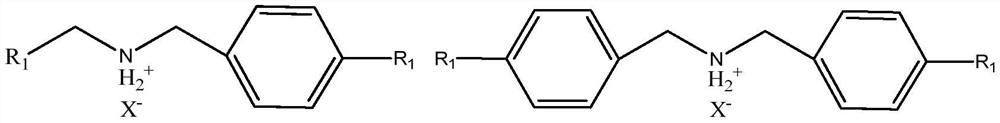

[0082] This embodiment provides a rotaxane crosslinking agent and a preparation method thereof. The preparation method is carried out according to the following synthetic route:

[0083]

[0084]

[0085] The preparation method specifically comprises the following steps:

[0086] Step 1: Add 100 parts of bisaldehyde dibenzo-24-crown-8 and 60 parts of dehydrated glycerol to 250 parts of tetrahydrofuran, then add 2 parts of p-toluenesulfonic acid catalyst, and heat to reflux at 100 ° C Stir azeotropically for 4 hours. The reaction solution was NaCO 3 washed with aqueous solution, and the organic layer was washed with K 2 CO 3 After drying, a white solid was obtained by rotary evaporation with a yield of 92%.

[0087] Product H NMR spectrum 1 HNMR (400MHz, CDCl 3 ), (TMS, ppm): δ=1.72-1.73 (two hydrogens on the six-membered ring of acetal); 3.49-3.51 (four hydrogens on the carbon to which the hydroxyl gro...

Embodiment 2

[0097] Embodiment 2: the preparation of polyurethane prepolymer (A)

[0098] Take 100 parts of Korean Kumho LL type liquefied MDI and 50 parts of polyether polyol of Nanjing Boben Polyurethane Co., Ltd. PPG-1000 type, add 0.1 part of stannous octoate catalyst, and accelerate the stirring reaction at 50 ° C for 2 hours . Then add 2 parts (ammonia value: 2 mmol / g, molecular weight: 1000) of amino-terminated amino silicone oil, and react for 1 hour. Thereafter, 5 parts of the cross-linking agent solution prepared in Example 1 were added, and the reaction was continued with stirring for 4 hours, followed by vacuum defoaming at 40° C. to 50° C. for 2 hours. The viscosity of the prepared polyurethane prepolymer (A) is 80000-125000mPa.s (25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com