Elastic polyurethane antibacterial material and preparation method thereof

A technology of elastic polyurethane and antibacterial materials, which is applied in the direction of pharmaceutical formulations and medical preparations of non-active ingredients, etc., can solve the problems of affecting the physical and mechanical properties of polymer materials, and the loss of use value of materials, so that the use value is not affected, good Physico-mechanical properties, effects of improving mechanical properties and deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

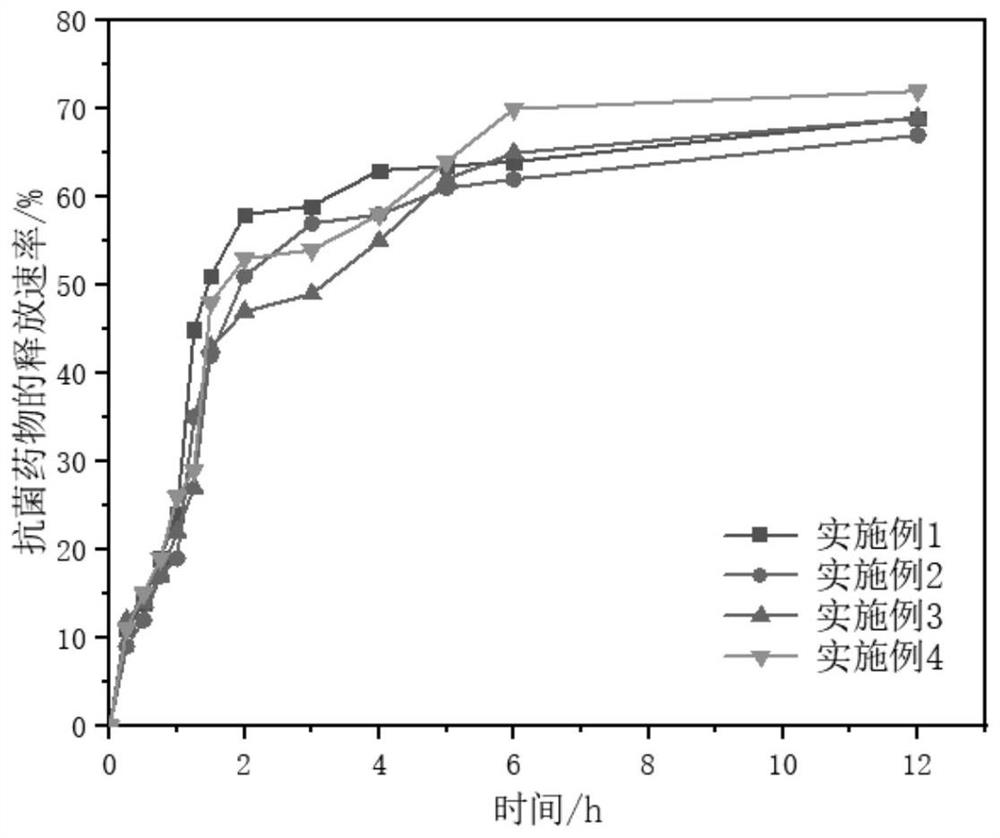

Examples

Embodiment 1

[0024] A preparation method of elastic polyurethane antibacterial material, comprising the steps of:

[0025] 1) Preparation of modified polypolyol

[0026] Add 15 parts by weight of tartaric acid and 150 parts by weight of polyethylene glycol with a molecular weight of 200-600 in a four-necked round bottom flask, then add 3 parts of catalyst 4-dimethylaminopyridine, and then keep the reactant at 60 ° C React for 1.5 hours; then raise the temperature to 120°C at a rate of 2°C per minute, and keep the temperature for 1 hour; finally cool the reaction mixture to 20°C to obtain the modified polypolyol;

[0027] 2) Preparation of polyurethane

[0028] Add 3 parts by weight of carvone and 2 parts by weight of emulsifier N-methyldiethanolamine to 30 parts by weight of modified polyol prepared in 1), and stir at 110° C. for 1.5 hours; then feed nitrogen into the reaction vessel Cool to 30°C; then add 55 parts by weight of hexamethylene diisocyanate and heat up to 60°C; add 1 part b...

Embodiment 2

[0030] A preparation method of elastic polyurethane antibacterial material, comprising the steps of:

[0031] 1) Preparation of modified polypolyol

[0032] Add 20 parts by weight of tartaric acid and 200 parts by weight of polypropylene glycol with a molecular weight of 400-2000 in a four-necked round bottom flask, then add 5 parts by weight of catalyst 4-dimethylaminopyridine, and then continue the reaction at 70 ° C 2.5 hours; then raise the temperature to 130°C at a rate of 3°C per minute, and keep the temperature for 2 hours; finally cool the reaction mixture to 30°C to obtain the modified polyol;

[0033] 2) Preparation of polyurethane

[0034] Add 5 parts by weight of cinnamaldehyde and 4 parts by weight of emulsifier N-methyldiethanolamine to 40 parts by weight of modified polyol prepared in 1), and stir at 120° C. for 2.5 hours; then feed nitrogen into the reaction vessel for cooling to 40°C; then add 60 parts by weight of cycloaliphatic diisocyanate, and heat up to...

Embodiment 3

[0036] A preparation method of elastic polyurethane antibacterial material, comprising the steps of:

[0037] 1) Preparation of modified polypolyol

[0038] Add the polyethylene adipate glycol of the tartaric acid of 25 weight parts and the molecular weight 400-1500 of 250 weight parts in the four-neck round bottom flask, add the catalyst 4-dimethylaminopyridine of 6 weight parts again, then will The reactant was continuously reacted at 80°C for 3.5 hours; then the temperature was raised to 135°C at a rate of 4°C per minute, and the temperature was kept for 3 hours; finally, the reaction mixture was cooled to 40°C to obtain the modified polypolyol;

[0039] 2) Preparation of polyurethane

[0040]Add 8 parts by weight of citral and 5 parts by weight of emulsifier N-methyldiethanolamine to 45 parts by weight of modified polyol prepared in 1), and stir for 4 hours at 140°C; then feed nitrogen into the reaction vessel for cooling to 50°C; then add 65 parts by weight of isophoron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com