Cable material and preparation method thereof

A cable material and mixing technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of difficult tensile strength, elongation, aging characteristics and flame retardant properties of cable materials, and achieve low cost. , Sufficient oil absorption, easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] At the same time, the embodiment of the present application also provides a preparation method for the above-mentioned cable material, including the following steps:

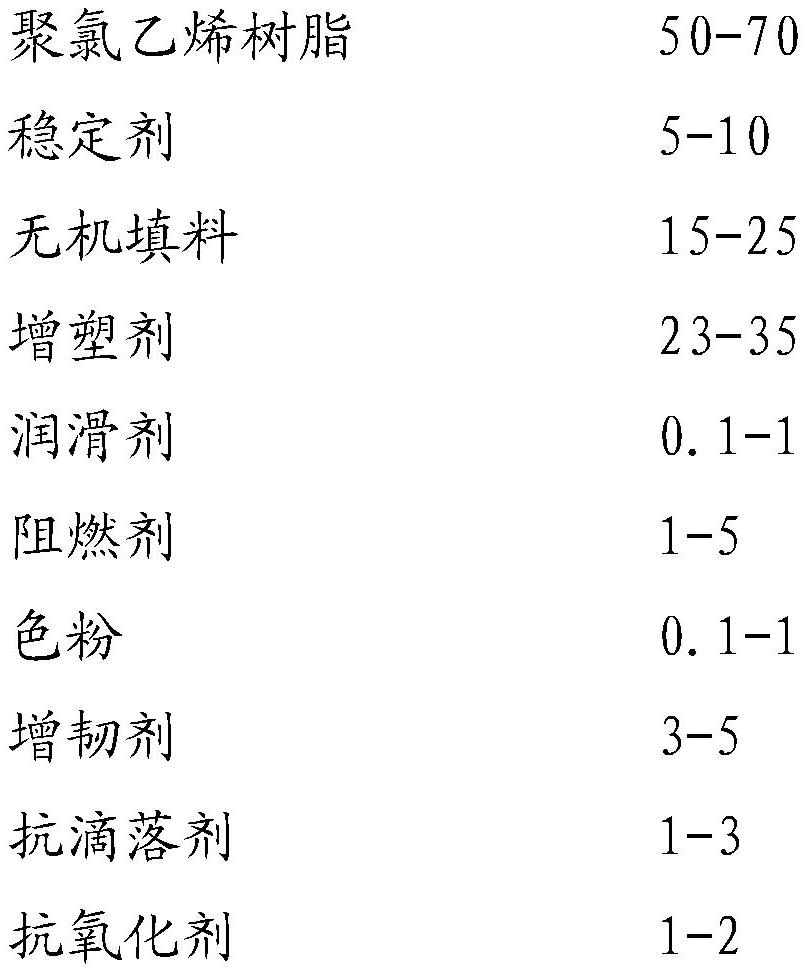

[0046] Preheating and mixing, preheating the mixing equipment to 35-40°C, adding 50-70 parts by weight of the polyvinyl chloride resin, 5-10 parts of the stabilizer, 15-25 parts of the inorganic filler, 23-35 parts of the plasticizer, 0.1-1 part of the lubricant, 1-5 parts of the flame retardant, 0.1-1 part of the toner, 3-5 parts of the toughening agent, 1-3 parts of the anti-dripping agent, 1-2 parts of the antioxidant, so that all components are uniformly mixed and dispersed to obtain a mixture of cable materials;

[0047] Pelletizing, placing the mixture in a granulating device for further mixing, plasticizing into a viscous substance, extruding and cutting into pellets to obtain the cable material.

[0048] In this preparation method, the main contribution to the prior art is that the mixing equipme...

Embodiment 1

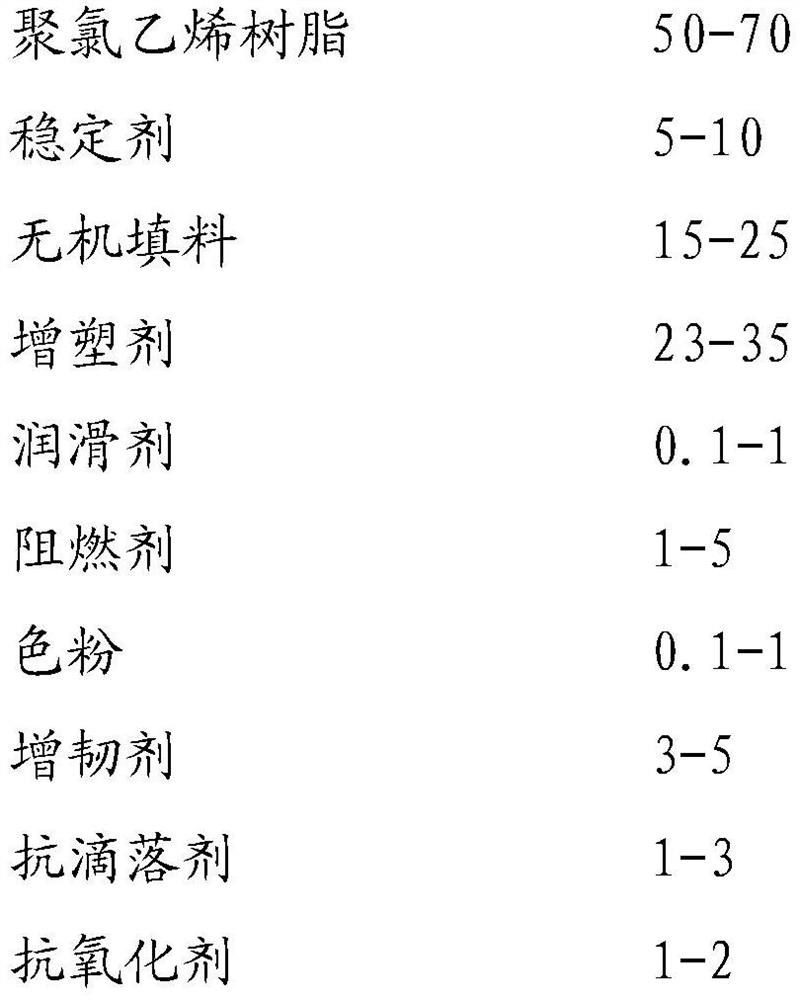

[0055] The embodiment of the present application provides a cable material, which includes the following components in parts by weight:

[0056]

[0057] Wherein, the inorganic flame retardant can be one or more in the halogen-free inorganic flame retardants such as aluminum hydroxide, magnesium hydroxide, and present embodiment preferably adopts aluminum hydroxide.

[0058] Among them, the toughening agent can be ethylene-vinyl acetate copolymer, styrene-butadiene thermoplastic elastomer, acrylonitrile-butadiene-styrene copolymer, vinyl chloride-polyvinylidene chloride copolymer, chlorinated polyvinyl chloride copolymer, One or more of ethylene, nitrile rubber, and polyvinyl acetate. In this embodiment, ethylene-vinyl acetate copolymer is preferably used.

[0059] Wherein, anti-dripping agent can be one or more in polytetrafluoroethylene anti-dripping agent, silicone powder anti-dripping agent, and present embodiment preferably adopts silicone powder.

[0060] Wherein, anti...

Embodiment 2

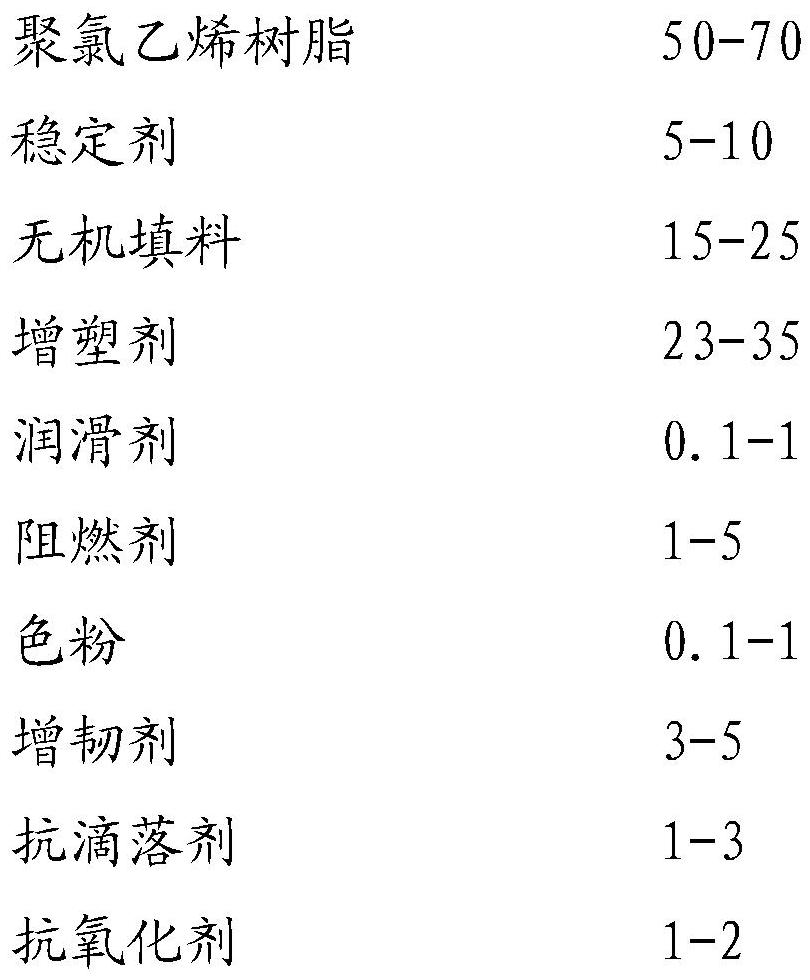

[0066] The embodiment of the present application provides a cable material, which includes the following components in parts by weight:

[0067]

[0068] Wherein, the inorganic flame retardant can be one or more in the halogen-free inorganic flame retardants such as aluminum hydroxide, magnesium hydroxide, and present embodiment preferably adopts aluminum hydroxide.

[0069] Among them, the toughening agent can be ethylene-vinyl acetate copolymer, styrene-butadiene thermoplastic elastomer, acrylonitrile-butadiene-styrene copolymer, vinyl chloride-polyvinylidene chloride copolymer, chlorinated polyvinyl chloride copolymer, One or more of ethylene, nitrile rubber, and polyvinyl acetate. In this embodiment, styrene-butadiene thermoplastic elastomer is preferably used.

[0070] Wherein, anti-dripping agent can be one or more in polytetrafluoroethylene anti-dripping agent, silicone powder anti-dripping agent, and present embodiment preferably adopts silicone powder.

[0071] Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com